Method of depositing hafnium silicate assisted by catalyst

一种沉积方法、催化剂的技术,应用在金属材料涂层工艺、气态化学镀覆、涂层等方向

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

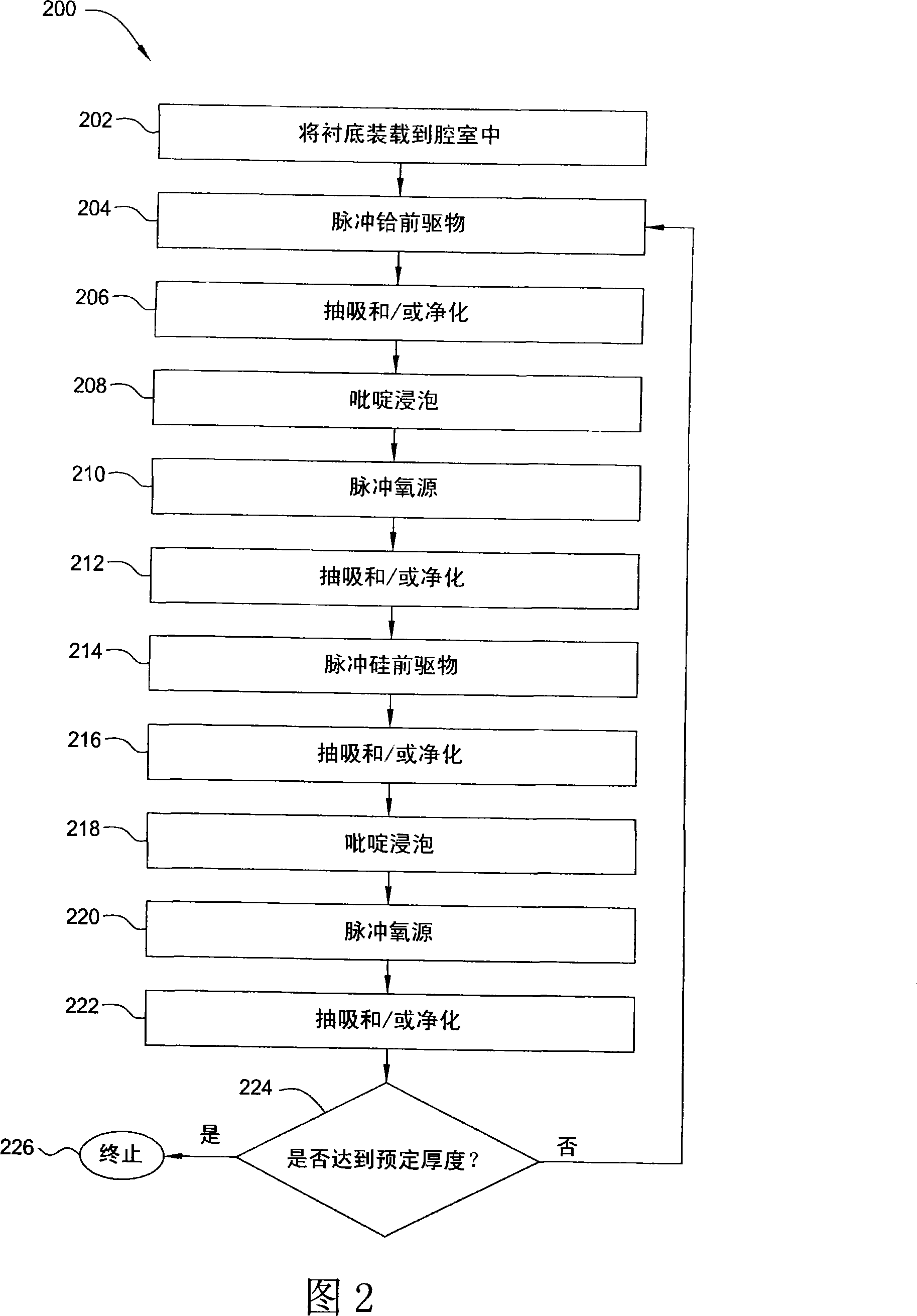

[0019] A hafnium silicate ALD method is described as an example of a high-k silicon method. To produce the hafnium silicate layer, the substrate may be exposed to pulses of hafnium precursors, pulses of oxidizing agents, pulses of silicon precursors, and pulses of other oxidizing agents. A siliconizing agent may additionally co-flow with one or more reactants into the chamber through a separate inlet. Alternatively, the siliconizing agent may flow into the chamber before the reactants are introduced into the soaking process. The hafnium silicate formation process can be performed rapidly and / or at low temperature by co-flowing with the catalyst through a separate inlet or by performing a catalyst soak.

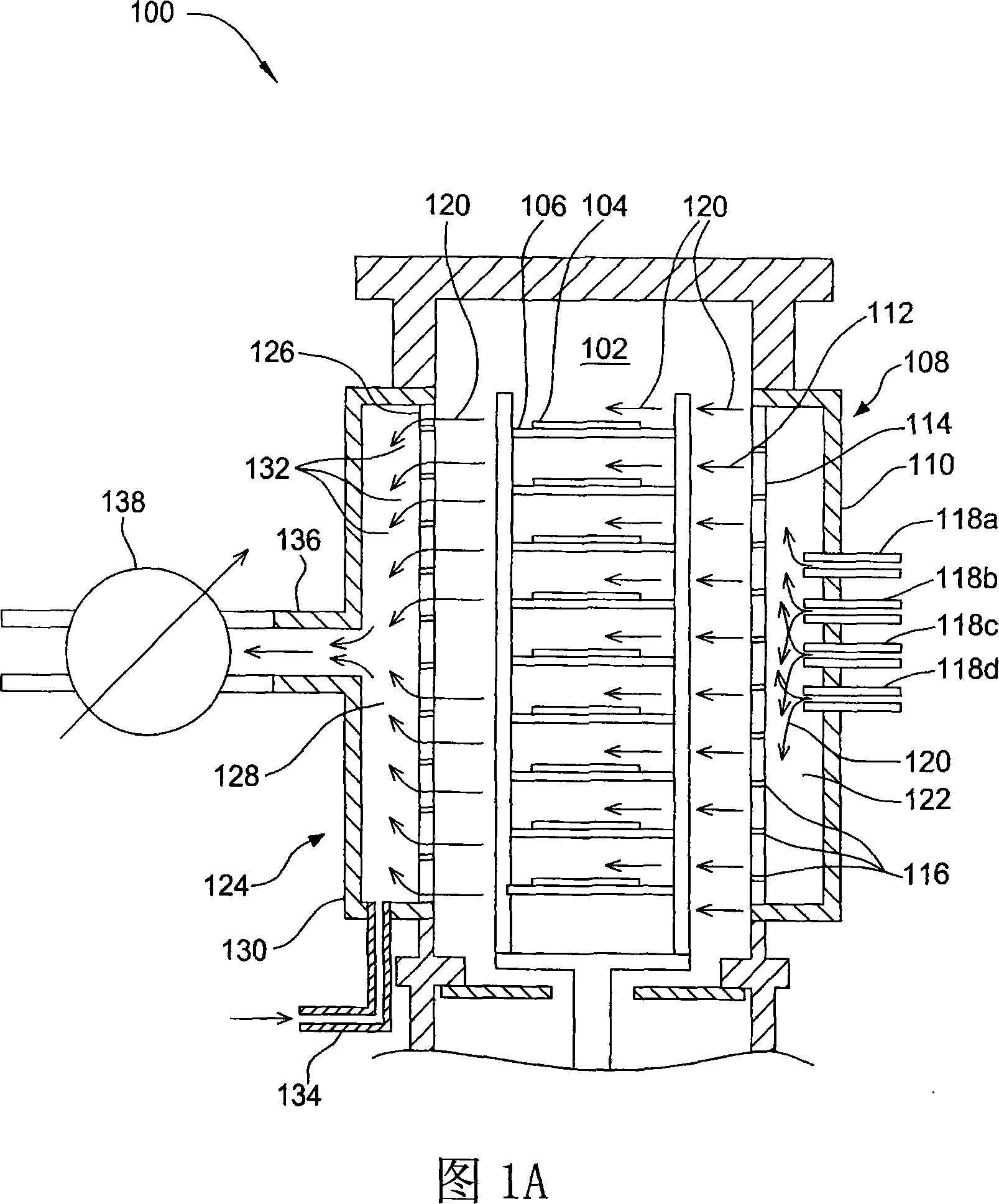

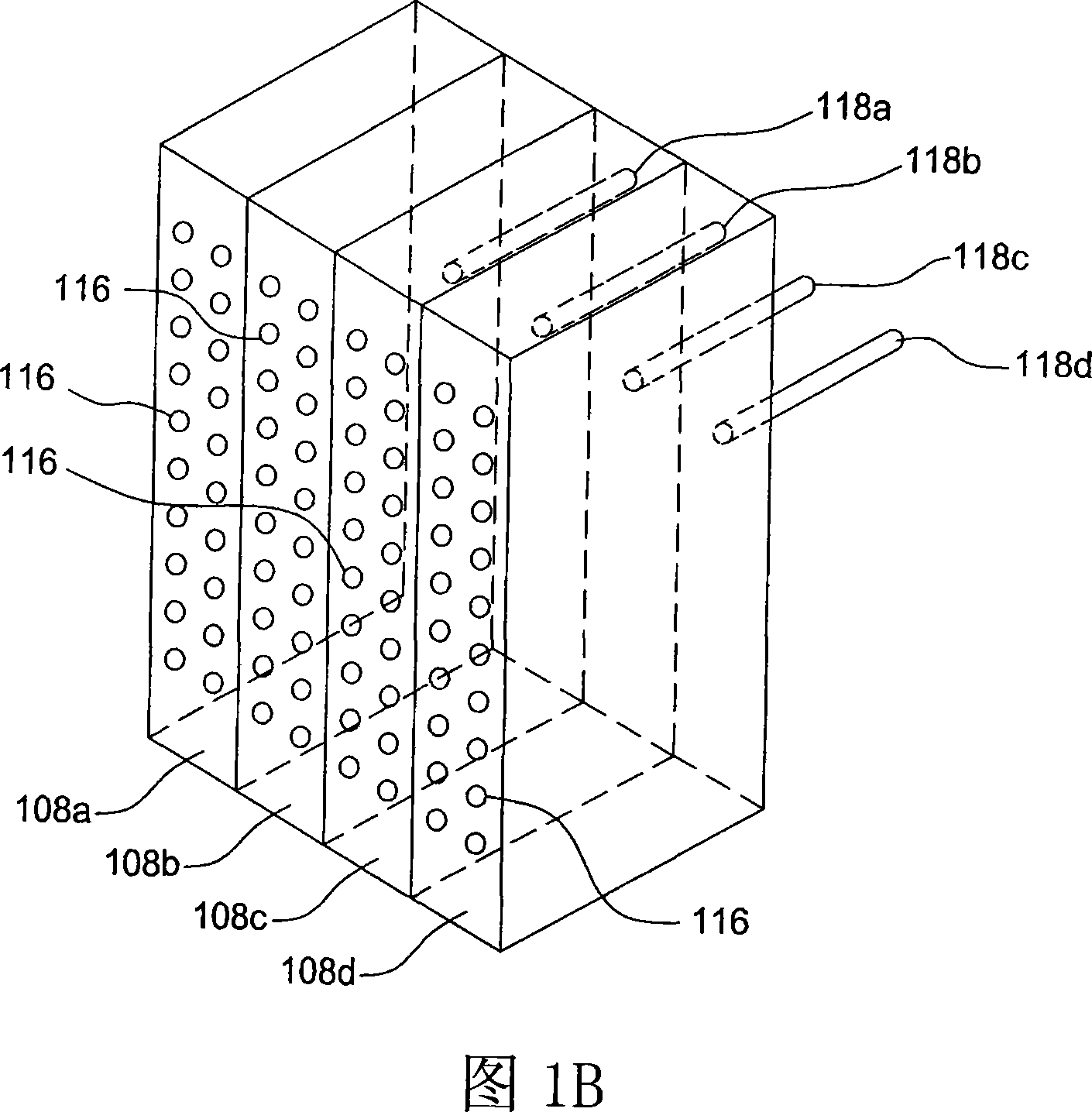

[0020] Figure 1A is a schematic view of an apparatus 100 according to one embodiment of the present invention. Apparatus 100 includes a vacuum chamber 102 . Apparatus 100 may be a batch processing apparatus 100 including one or more susceptors 106 upon which substrates 104 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com