Little oil ignited swirling pulverized coal combustion device

A pulverized coal combustion and low-oil ignition technology, which is applied in the direction of using multiple fuels for combustion, combustion ignition, and combustion methods, can solve the problems of energy waste, large oil consumption, and high pollutant emissions from coal-fired boilers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

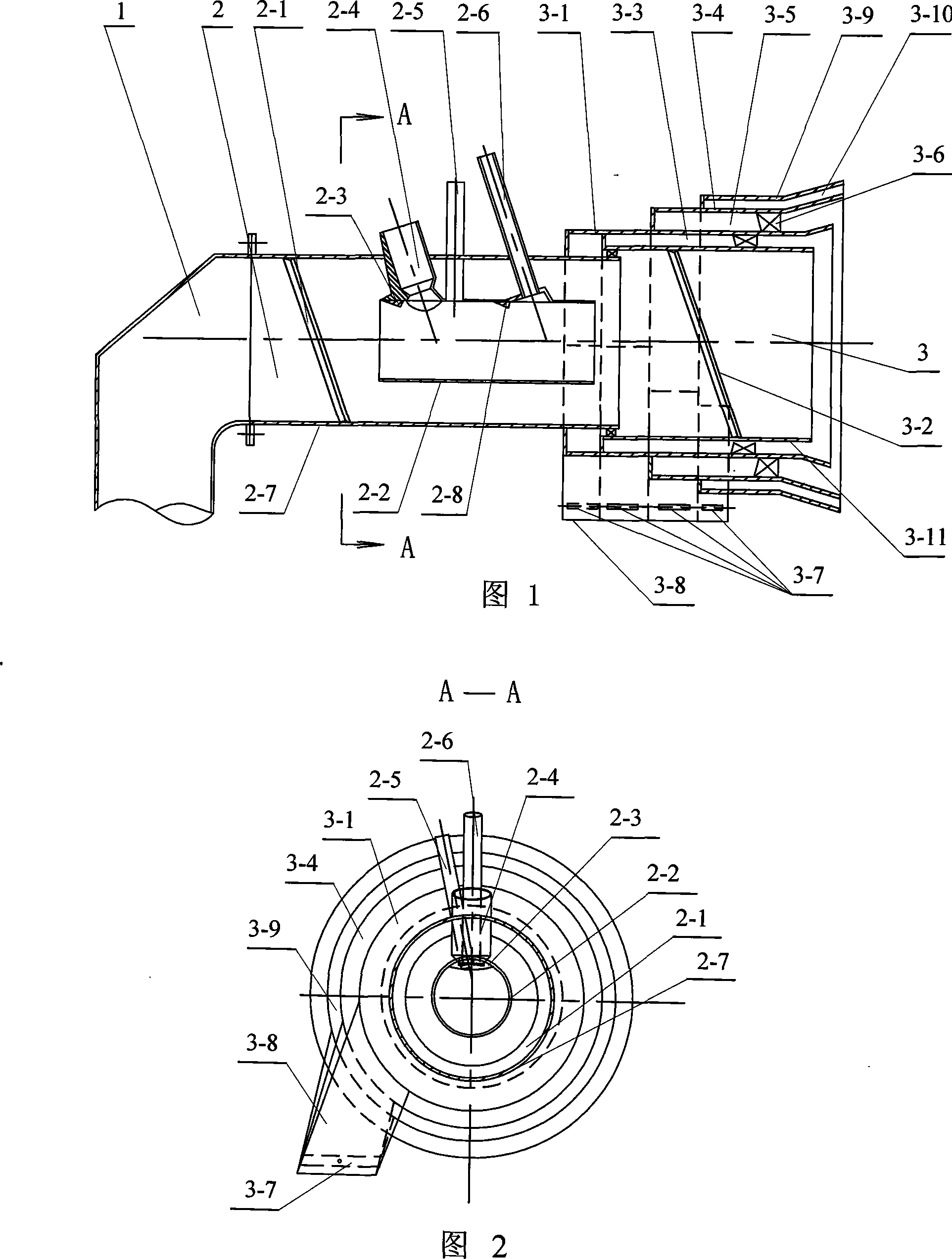

[0005] Specific embodiment one: (see Fig. 1, Fig. 2) present embodiment is made up of coal-fired ignition device 2 and graded burner 3, and coal-fired ignition device 2 is made up of oil, coal burner pipe 2-2, main fuel oil pipe 2- 4. Composed of fire detection pipe 2-5, auxiliary fuel pipe 2-6 and outer pipe 2-7, oil and coal burner pipe 2-2 is set on the outlet side of outer pipe 2-7, main fuel pipe 2-4 The outlet end of the main fuel pipe 2-4 is fixedly connected with the outer pipe 2-7, and the outlet end of the auxiliary fuel pipe 2-6 is connected with the oil and coal burner pipe 2-2. One side of the outlet end of the burner pipe 2-2 is connected, the middle part of the auxiliary fuel pipe 2-6 is fixedly connected with the outer pipe 2-7, and the flame detection pipe 2-5 is arranged on the main fuel pipe 2-4 and the auxiliary fuel pipe 2- 6, one end of the flame detection pipe 2-5 is connected with the oil and coal burner pipe 2-2, and the middle part of the flame detect...

specific Embodiment approach 2

[0006] Specific embodiment two: (referring to Fig. 1, Fig. 2) the difference between this embodiment and specific embodiment one is that the cross-sectional area of the oil and coal burner pipe 2-2 inlet end is less than the cross-sectional area of the outlet end. Other compositions and connections are the same as in the first embodiment. Changing the structure of the oil and coal burner tube 2-2 can make the pulverized coal gradually diffuse and fully mix with the oxygen added by the swirling wind on the inner wall, which is beneficial to the combustion and the fullness of the flame at the outlet of the pulverized coal combustion device.

specific Embodiment approach 3

[0007] Specific embodiment three: (referring to Fig. 1, Fig. 2) the difference between this embodiment and specific embodiment one is that the cross-sectional area of the oil and coal burner pipe 2-2 outlet end is equal to the cross-sectional area of the inlet end. Other compositions and connections are the same as in the first embodiment. Changing the structure of the oil and coal burner tube 2-2 can increase the amount of concentrated coal powder and reduce the amount of air, so that the burning coal powder is gradually diffused and fully mixed with the oxygen added by the swirling wind on the inner wall.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com