Encapsulated, flameproof, not hermetically sealed, rotationally symmetrical high-performance spark gap

A technology of rotational symmetry and spark gap, which is applied to spark gaps with auxiliary trigger devices, spark gaps, overvoltage arresters using spark gaps, etc., can solve problems such as unsuitability for low-voltage power grids, improve mechanical characteristics, and increase combustion rate , the effect of high mechanical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

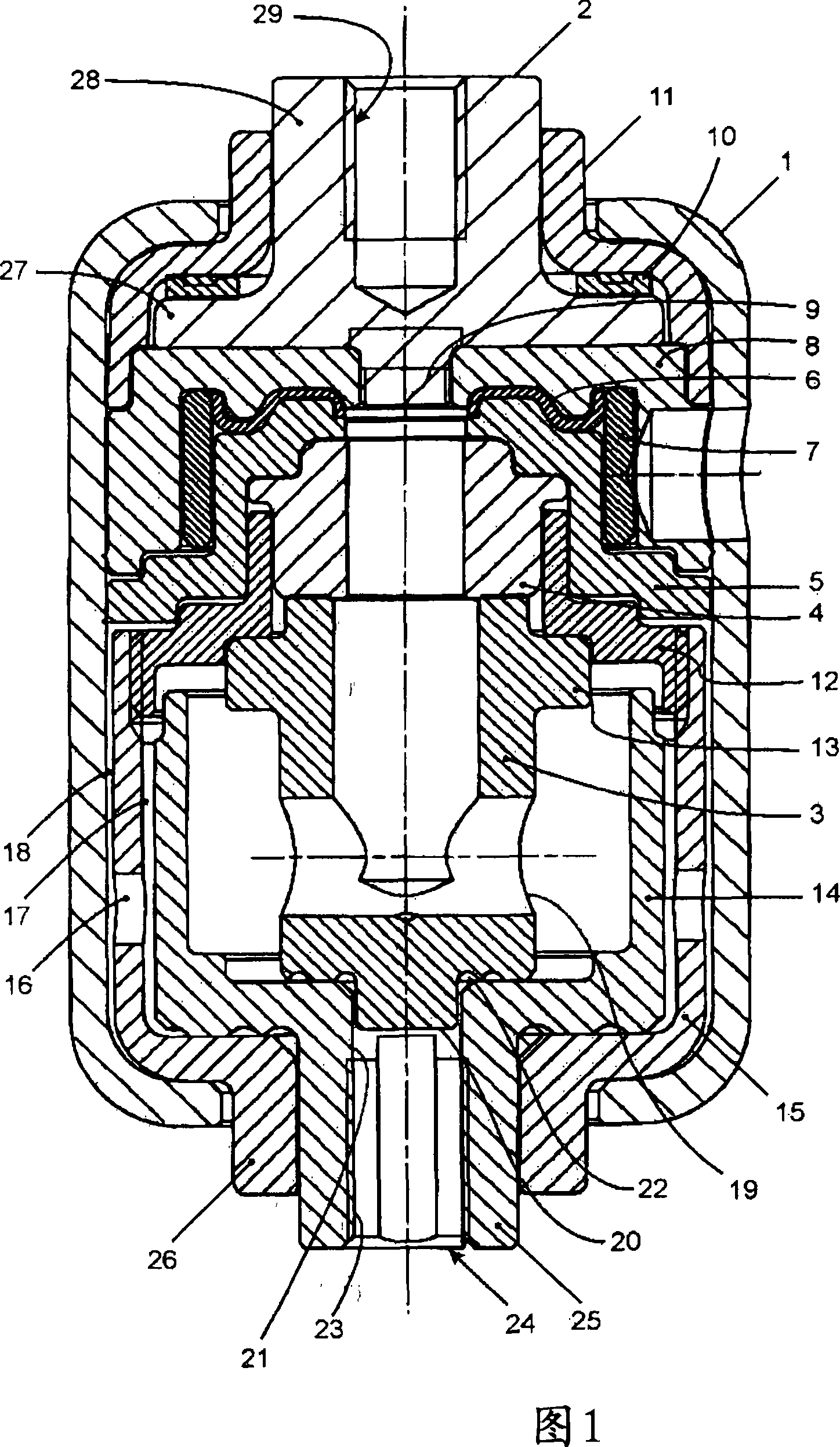

[0046] In the spark gap according to FIG. 1 , the active part and the passive part are arranged inside the housing 1 .

[0047] Firstly, in order to form a pressure-resistant cooling chamber, an inner cup 14 is provided, which is surrounded by an outer cup 15 at intervals for maintaining the gas cooling channels 17 .

[0048] One of the main electrodes protrudes into the cavity interior of the cup 14 as the electrode of the hollow-cylindrical blow-out electrode 3 .

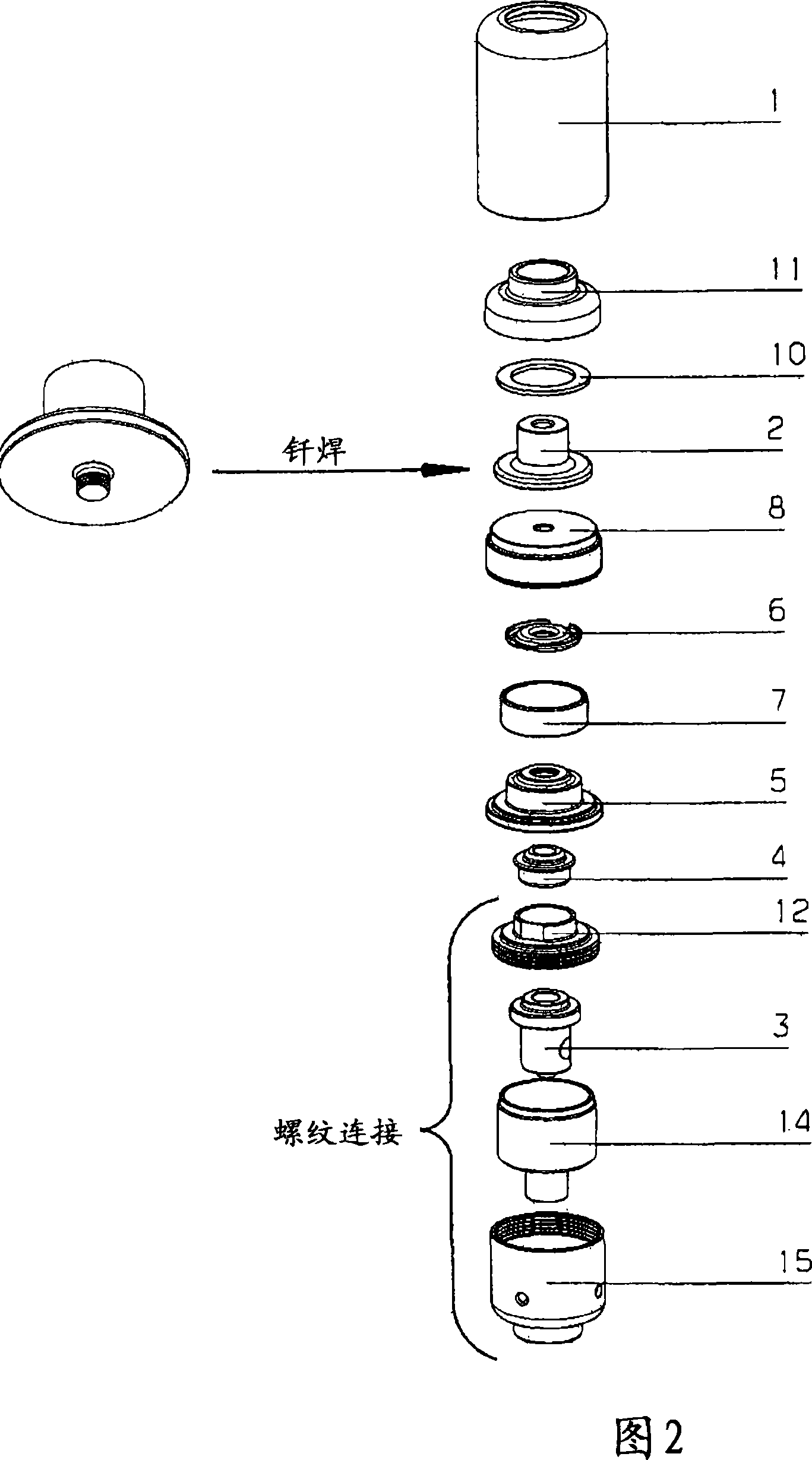

[0049] On the open side of the cup structure there is provided a support ring 12 which laterally surrounds the blow-off electrode 3 . The support ring 12 has an external thread corresponding to the internal thread on the outer cup 15 (see FIG. 2 ).

[0050] Lateral air outlet openings 16 are provided on the outer cup 15 , wherein at least the aforementioned gas cooling channels 17 are formed between the inner cup 14 and the outer cup 15 , and at the outer cup 15 Another slit-shaped gas cooling channel 18 is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com