Condenser microphone for smd using sealing pad and method of making the same

A technology of condenser microphones and microphones, applied in the direction of electrostatic transducer microphones, sensors, electrical components, etc., can solve the problems of reduced productivity and poor appearance, and achieve the effects of reduced defective rate, simplified manufacturing process, and low height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

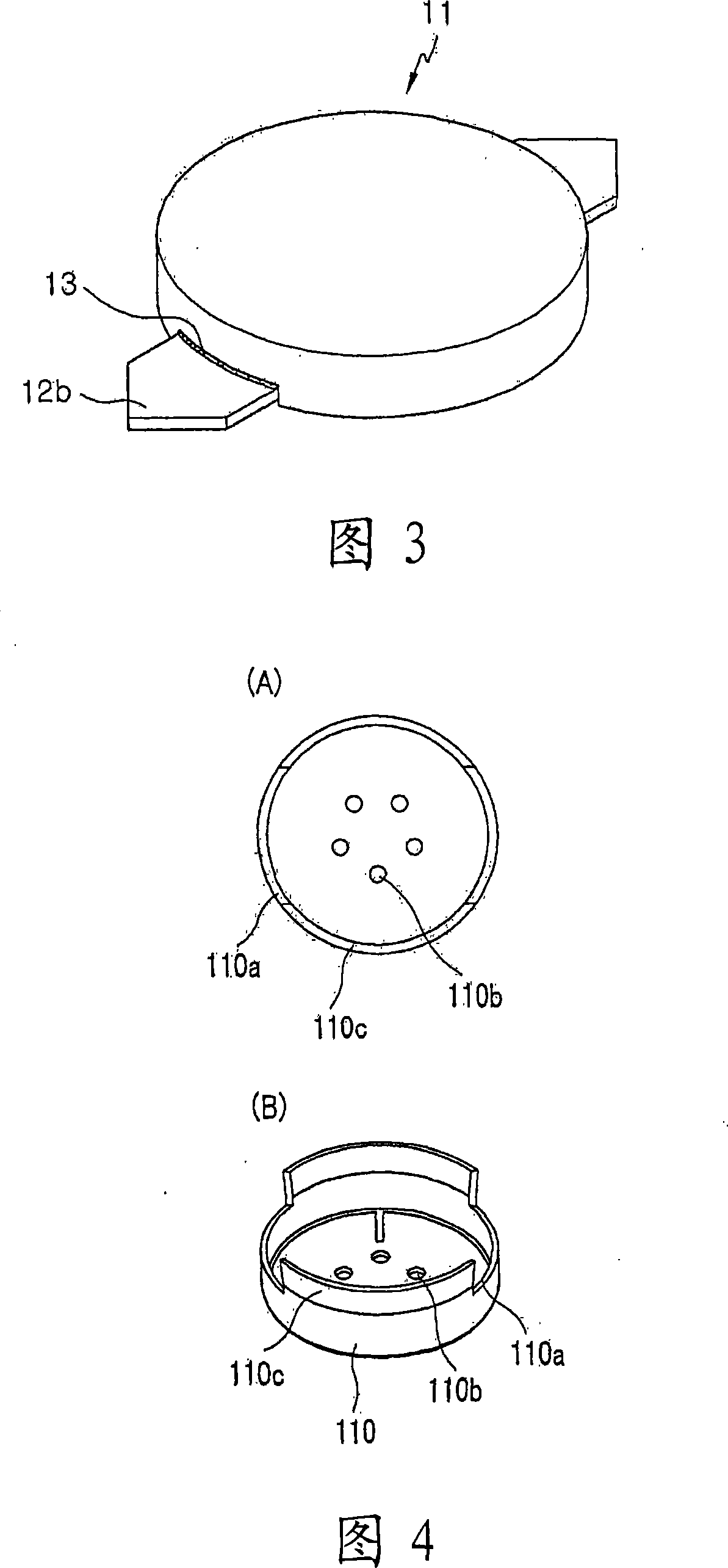

[0042] As shown in FIG. 7, the method of manufacturing a condenser microphone using the above-mentioned main components according to the first embodiment of the present invention includes: a step S11 of preparing a casing 110; a step S12 of attaching a gasket 120 to the groove 110a of the casing ; a step S13 of inserting the internal components into the case 110; a step S14 of inserting the PCB 130; and a step S15 of crimping the protruding portion of the case.

[0043] Referring to FIG. 7, in step S11, the casing 110 having the groove 110a formed therein as shown in FIG. 4 is prepared, and in step S12, the gasket 120 shown in FIG. slot 110a. In step S13, such as a vibrating plate, a spacer, a first substrate, an electret backplane, and a second substrate are inserted into the housing 110, and in step S14 an integrated PCB with a tube 130a as shown in FIG. 130 is inserted into the housing 110 . The components inserted in step S13 may vary depending on the type of microphone....

no. 2 approach

[0048] 11 is a flowchart showing a manufacturing process of the condenser microphone according to the second embodiment of the present invention, and FIG. 12 is a diagram showing the condenser microphone according to the second embodiment of the present invention.

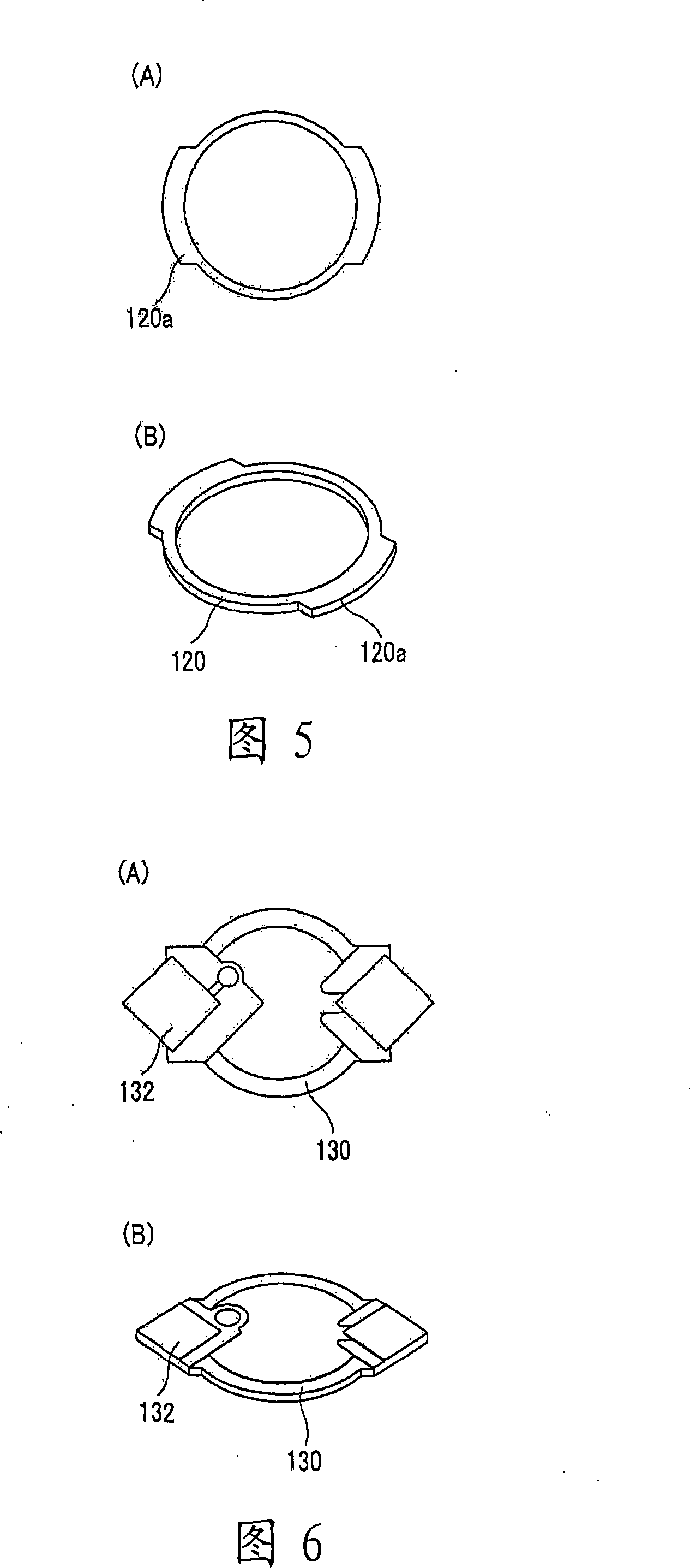

[0049] As shown in FIG. 11 , the manufacturing process of the condenser microphone according to the second embodiment of the present invention includes: a step S21 of preparing the casing 110; a step S22 of inserting internal components into the casing 110; Step S23 on the ring 140; step S24 of inserting the PCB 130; and step S25 of crimping the protruding portion of the case.

[0050] (A) and (B) of FIG. 12 are respectively a plan view and a side view showing a state where a gasket is stacked on an insulating ring, and (C) of FIG. 12 is a view showing a condenser microphone according to a second embodiment of the present invention. Side cutaway view. Referring to (C) of FIG. 12 , the vibrating plate 150 and the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com