Buffering bicycle frame

A bicycle and frame technology, which is applied in the field of cushioning bicycle frames, can solve problems such as uncomfortable shoulders and heads, unsatisfactory shock absorption effects, etc., and achieve the effects of reducing bearing capacity, alleviating vibration or collision, and reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

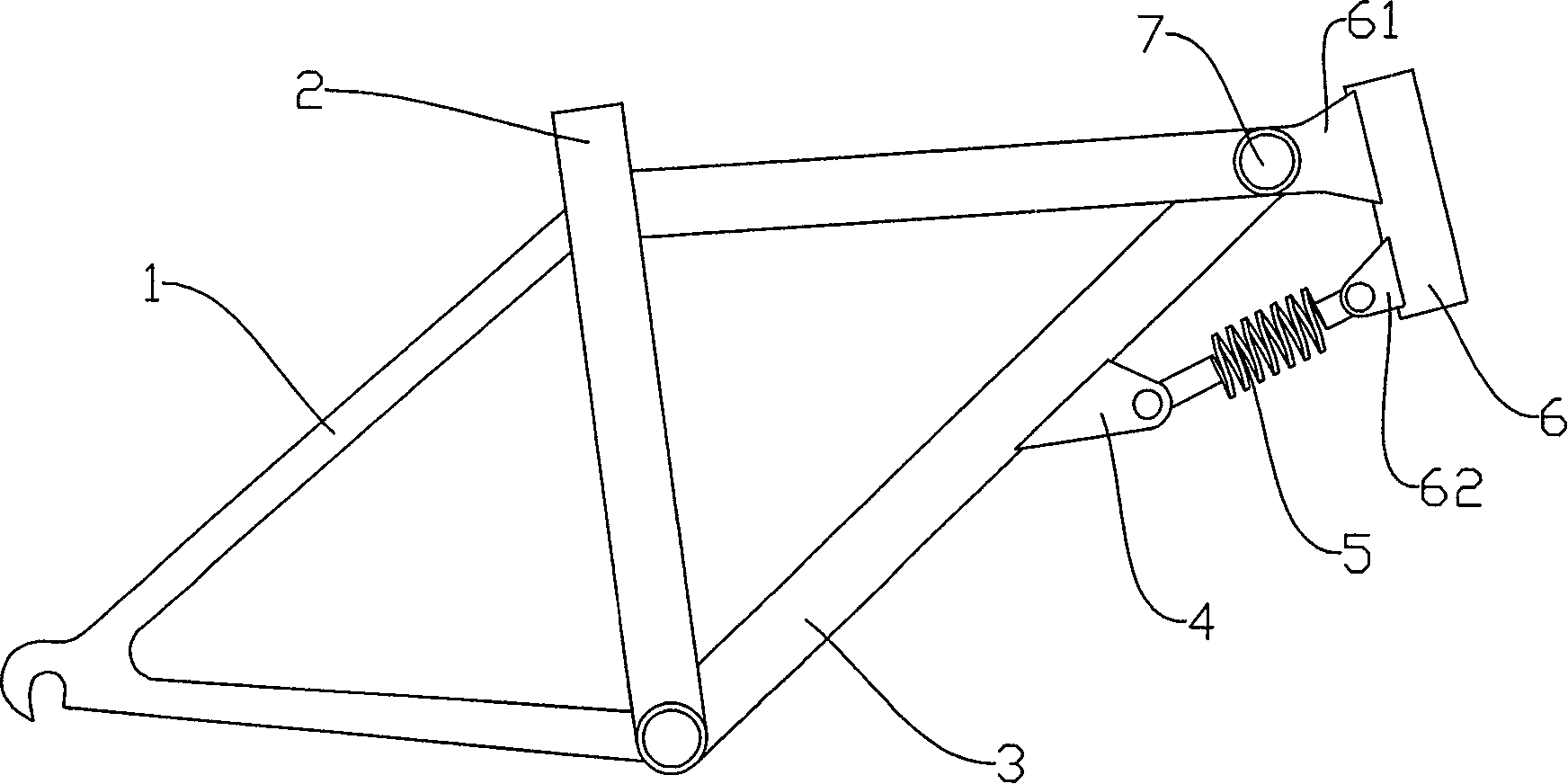

[0016] Embodiment 1, as attached figure 1 as shown in:

[0017] In this embodiment, the present invention includes a front tripod 3 and a rear tripod 1. In order to reduce the bearing capacity of the front fork and reduce the vibration of the headstock during travel, the present invention includes a headstock that is movably connected with the front tripod 3 Tube 6. A connecting piece is arranged on the head tube 6 , and a rotating shaft 7 is arranged on the connecting piece 61 , and the front tripod 3 is movably connected with the front tripod 3 through the rotating shaft 7 . A shock absorber 5 is arranged between the described head pipe 6 and the front tripod 3 . The shock absorber 5 is a shock absorber spring; one end of the shock absorber spring is connected to the front tripod through the connectors 4, 62, and the other end is connected to the head pipe 6. The connecting piece is to take and pay.

[0018] When the user needs to brake in an emergency or the road is rou...

Embodiment 2

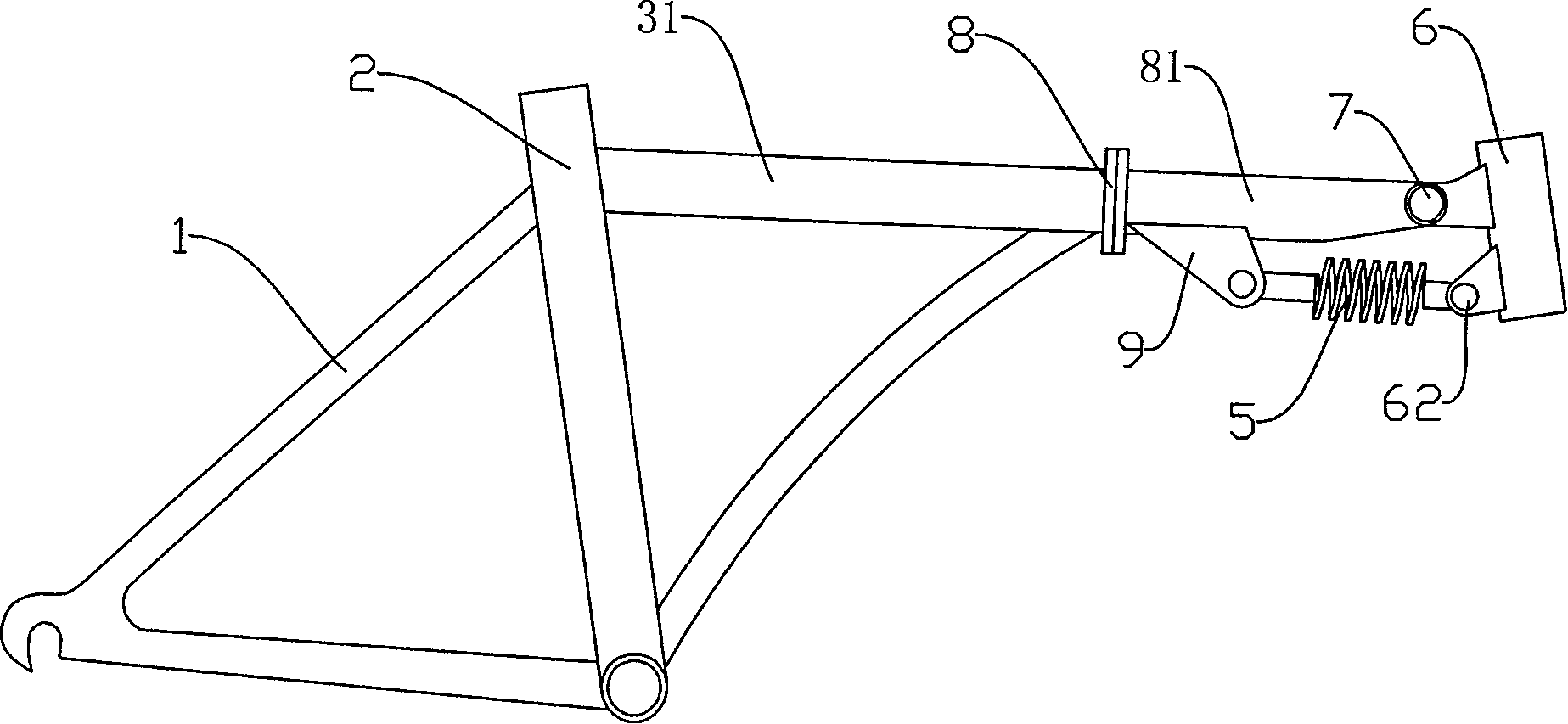

[0019] Example 2, such as figure 2 as shown in:

[0020] In this embodiment, the front tripod 3 is a folding front tripod with a folding shaft 8 , and the head end portion 81 of the folding front tripod is flexibly connected to the head tube 6 . A connecting piece 9 is arranged on the head end portion 81 of the front tripod 3 , the shock absorber 5 is connected to the connecting piece 9 , and the other end of the shock absorber is connected to the head pipe 6 .

[0021] The other parts of this embodiment are exactly the same as the embodiment.

Embodiment 3

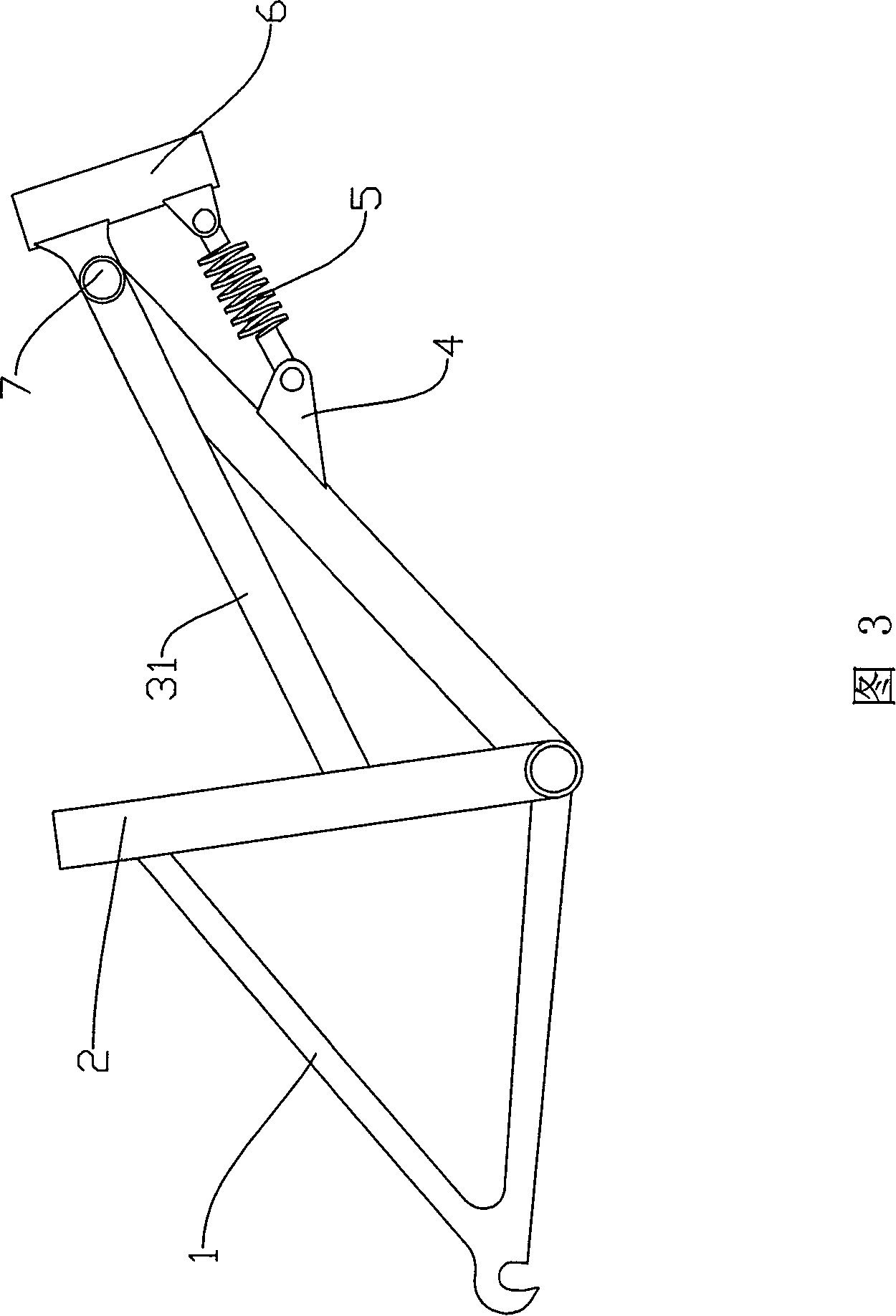

[0022] Embodiment 3, as shown in Figure 3:

[0023] In this embodiment, the front tripod 3 is a triangular front tripod, wherein the angle between the side of the beam 31 and the side of the vertical beam 2 is greater than 90°.

[0024] Other parts of this embodiment are the same as Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com