Heavy load balance mechanism

A technology of balancing mechanism and heavy load, applied in cranes, manipulators, mechanically driven excavators/dredgers, etc., can solve the problems of small balancing torque, complex assembly, small preload force, etc., to meet the requirements of large swing and simplify Assembly, the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

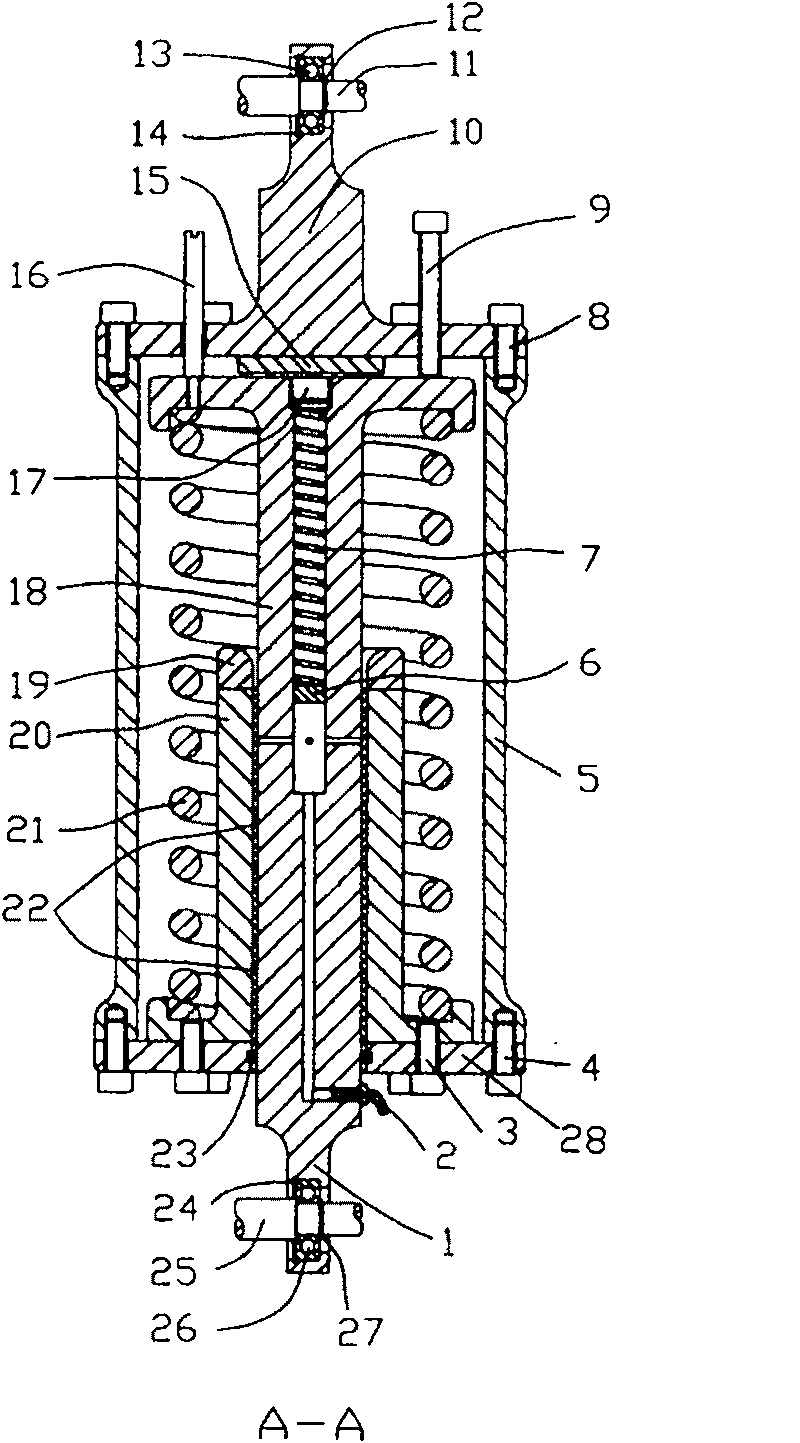

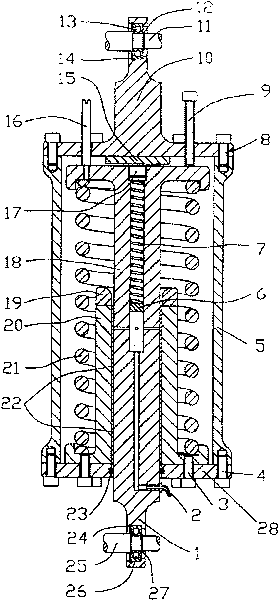

[0016] see figure 1 , an embodiment of the present invention, the heavy load balance mechanism includes a telescopic shaft assembly, a fixed shaft assembly, a compression spring, a fixed assembly, a guide assembly and a preload assembly, and the fixed assembly is passed through screws (including the first screw 8 and the second screw 3 ) connect the fixed shaft and the guide assembly, and the compression spring connects the guide assembly and the telescopic shaft assembly.

[0017] The telescopic shaft assembly includes a telescopic shaft 1, a first bearing 26, a first rotating shaft 25, a first large retaining ring 24, a first small retaining ring 27, a grease nipple 2, an extruding spring 7, a slider 6 and an oil plug 17, The slide block 6 is packed into the grease storage area in the middle of the telescopic shaft 1 to seal the storage area. The telescopic shaft 1 is also provided with an oil passage leading to the reciprocating bearing 22, and then the extrusion spring 7 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com