Bottom wire-cutting device capable of adjusting length of cut suture line

A thread cutting and sewing technology, which is applied in the sewing machine to cut off the thread mechanism, sewing equipment, sewing machine components, etc. It can solve the problems of complicated procedures, affecting the appearance of the product, and the inability to adjust the cutter.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to understand more clearly the technical content of the present invention, the purpose of the invention and the effects it can achieve, the preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings:

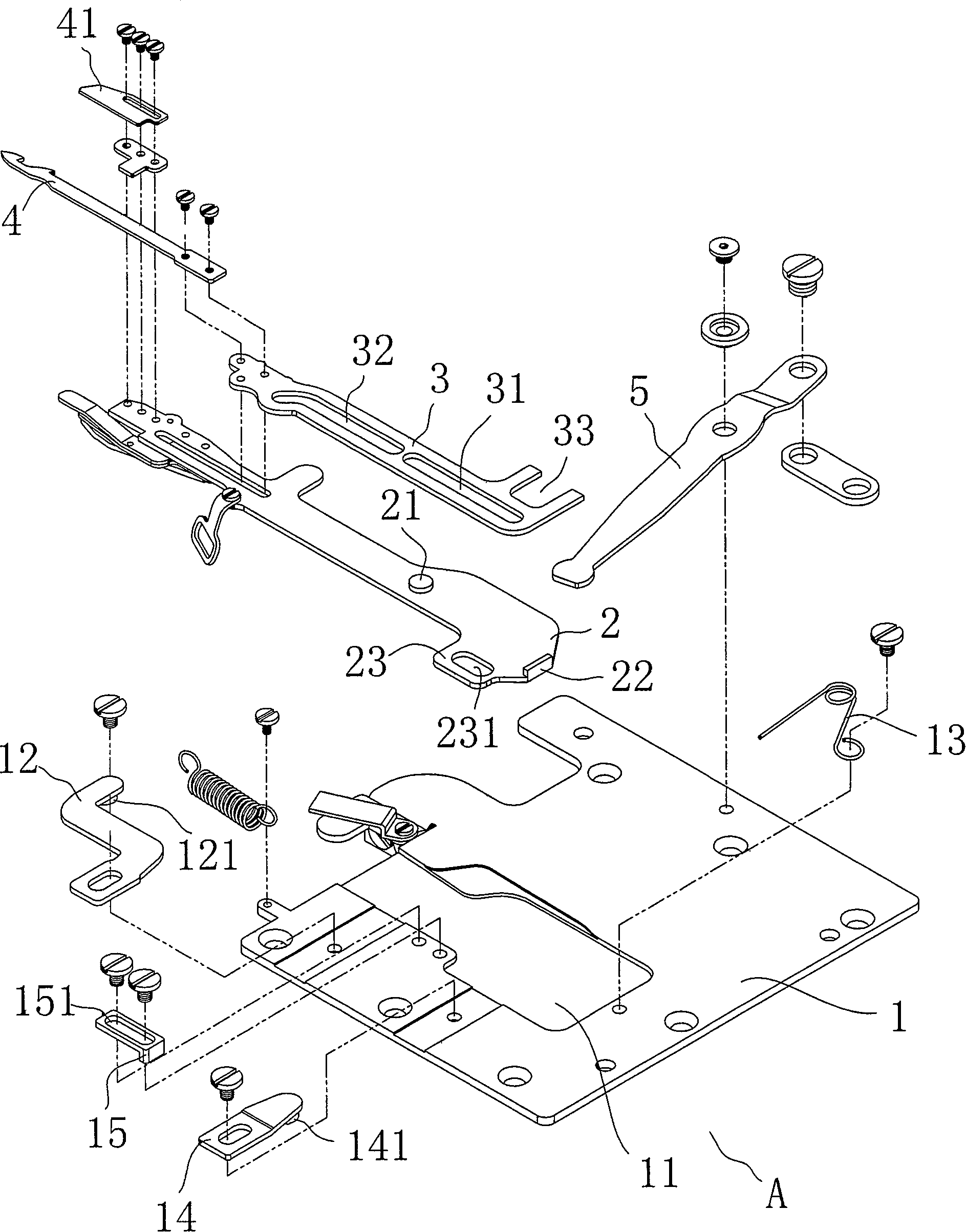

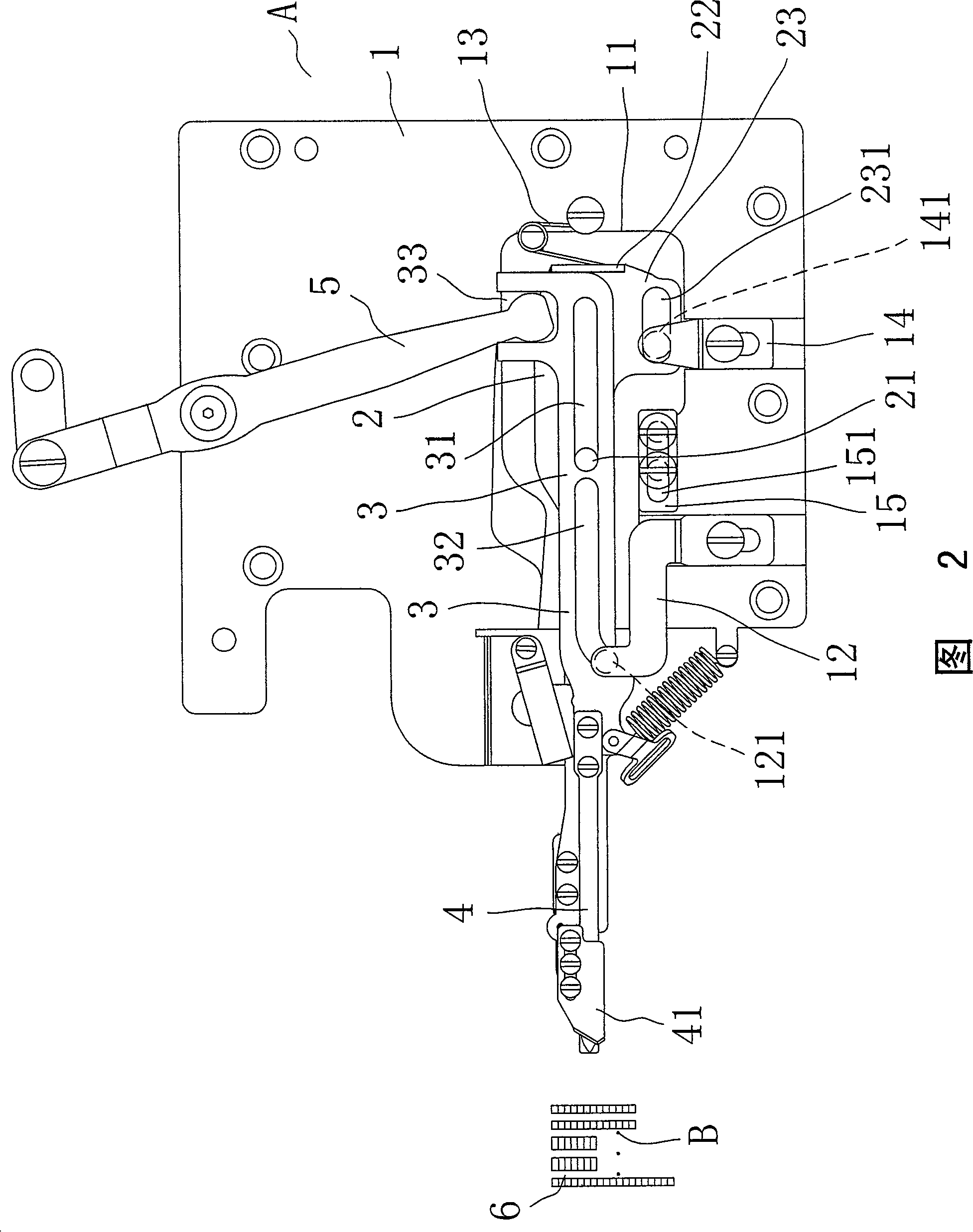

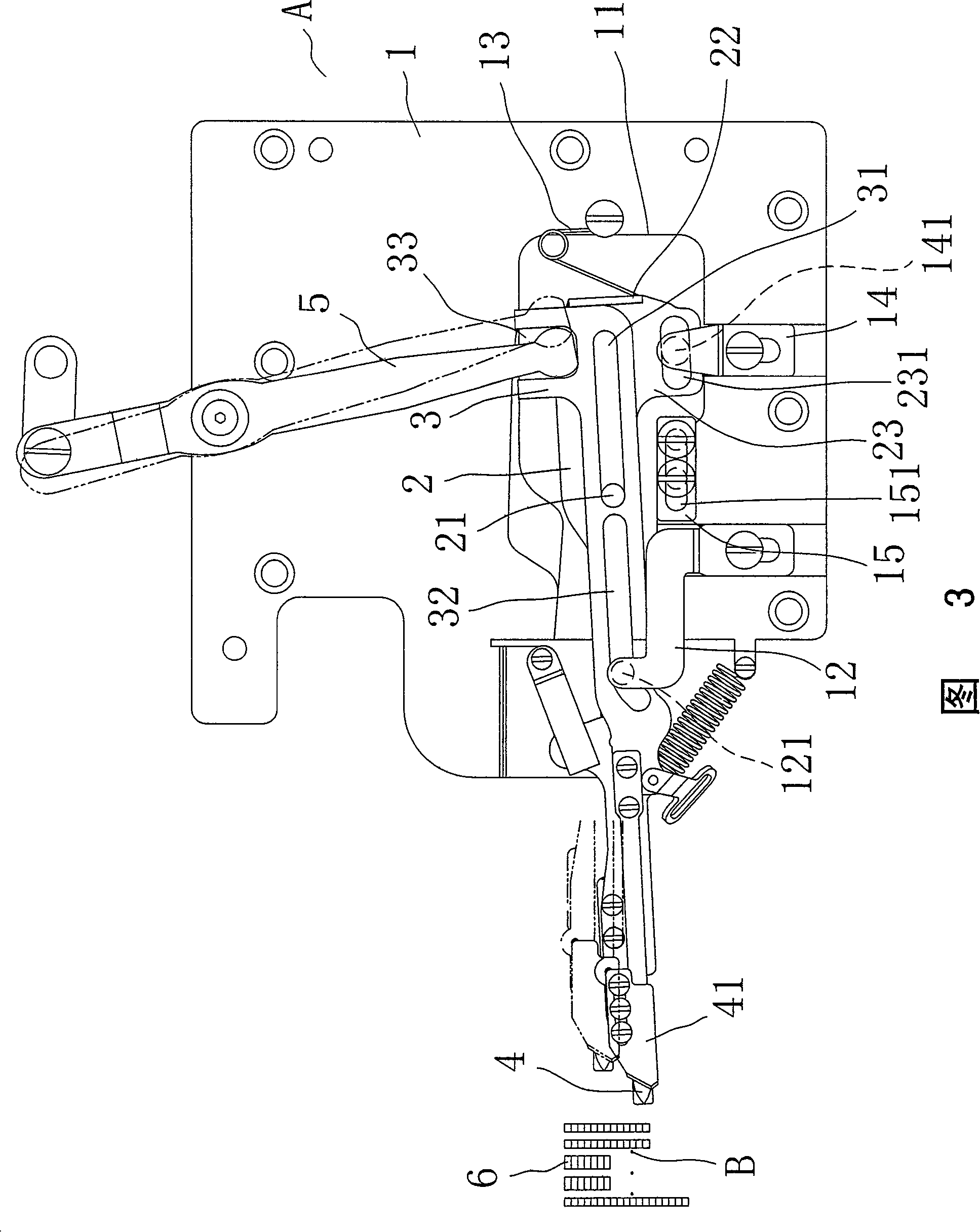

[0021] First, see figure 1 As shown, it is an overall exploded schematic view of the lower thread trimming device of the present invention that can adjust the length of the cut suture. The lower thread trimming device A is correspondingly assembled on the side of the needle suture. Correspondingly set a knife seat 2 in the groove 11, the front end of the knife seat 2 is provided with a blade 41, and a movable seat 3 with a guide groove 31 is correspondingly sleeved at the protrusion 21 of the knife seat 2, and the front end of the movable seat 3 is assembled with a Hook knife 4, the hook knife 4 can protrude from the blade 41 to hook the sewing thread, and then there is a turning groove 32 in front...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com