Machine tool with two clamp points on separate carriages

A clamping position, machine tool technology, applied in milling machines, milling machine equipment, manufacturing tools, etc., can solve problems such as unfavorable workpieces, workpiece accessibility limitations, and difficulty in achieving machine rigidity, etc., to improve machining accuracy and high machining accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

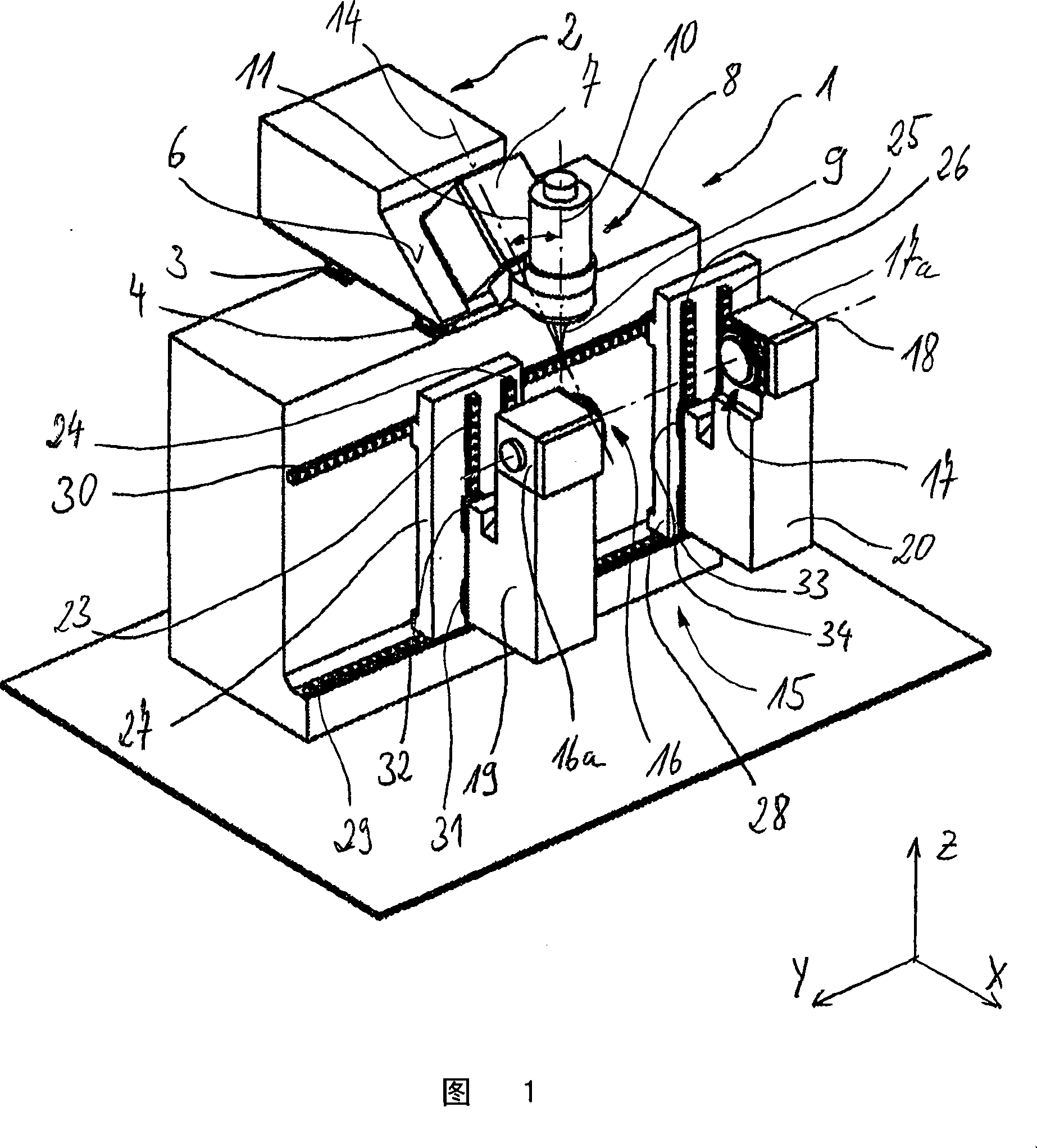

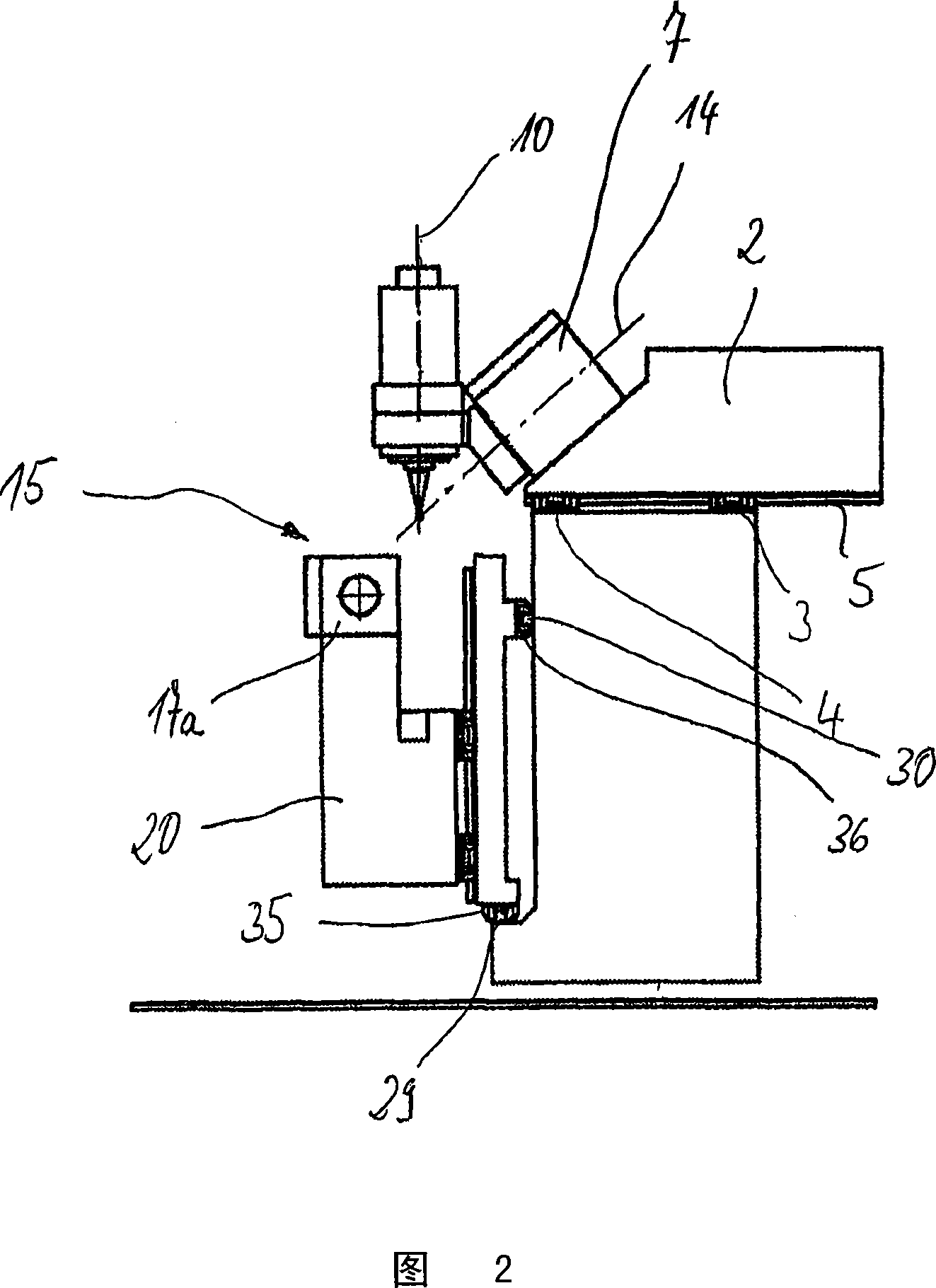

[0018] The machine tool shown very simply in FIG. 1 has a frame 1 on the upper side of which a first slide 2 is arranged. The slide 2 is movable in the X direction of the Cartesian coordinate system. The carriage 2 is displaceable via two linear displacement guides running parallel to one another, wherein a corresponding number of tool holder seats 3 , 4 are arranged on a linear displacement guide 5 . Only one of the guide rails 5 can be seen in the figure. In the tool carrier seats 3 , 4 on the linear movement guide, which has been mentioned several times before, the rolling bodies circulate in the circulation channel. In this case, the tool holders 3 , 4 are fixed on the frame 1 in a fixed position, while the guide rail 5 is mounted on the movable slide 2 .

[0019] The slide 2 is provided with an inclined surface 6 on which a tool slide 7 is arranged. The tool slide 7 is displaceable on this surface 6 in the X-direction and in the Z-direction by means of two further line...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com