Film tension control method in film production

A control method, film tension technology, applied in thin material processing, winding strip, transportation and packaging, etc., can solve the problems of poor absolute accuracy, inability to absorb, difficult to handle acceleration and deceleration, and achieve high stability and instant response , high durability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

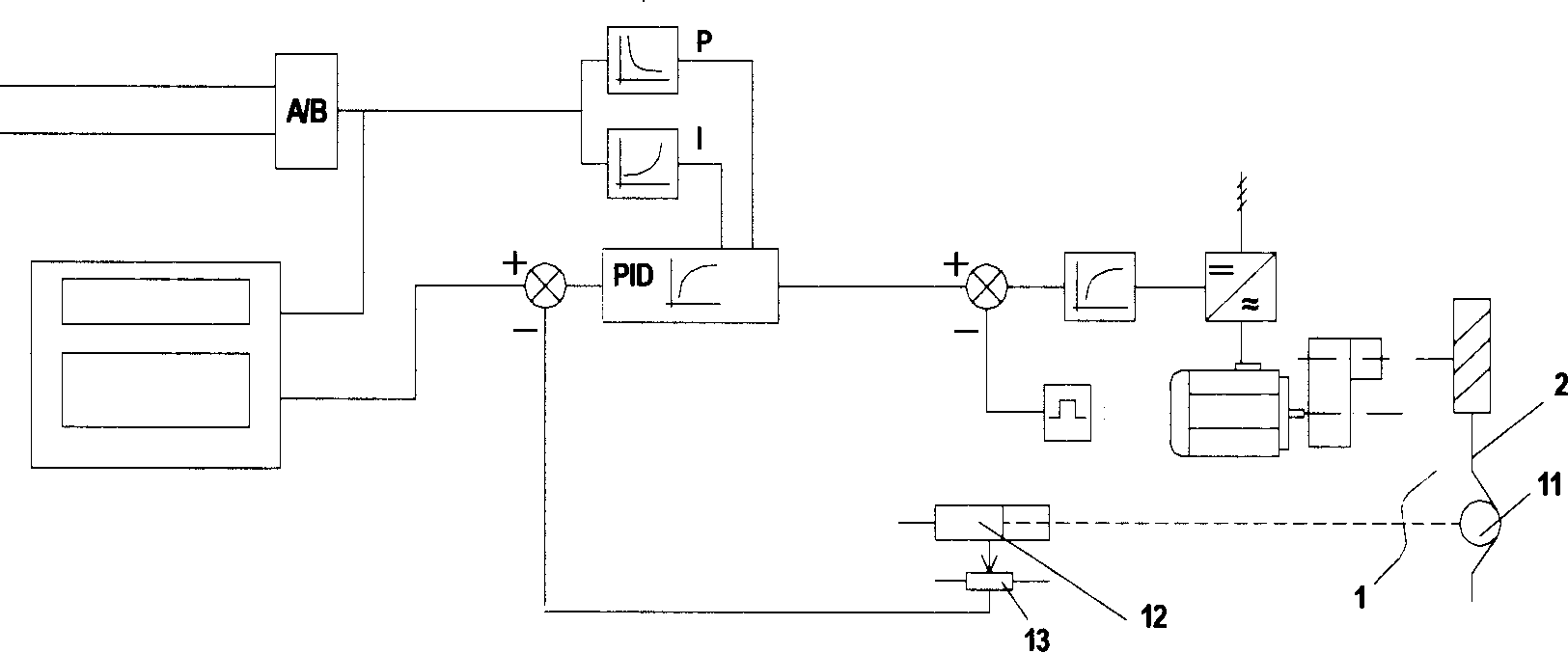

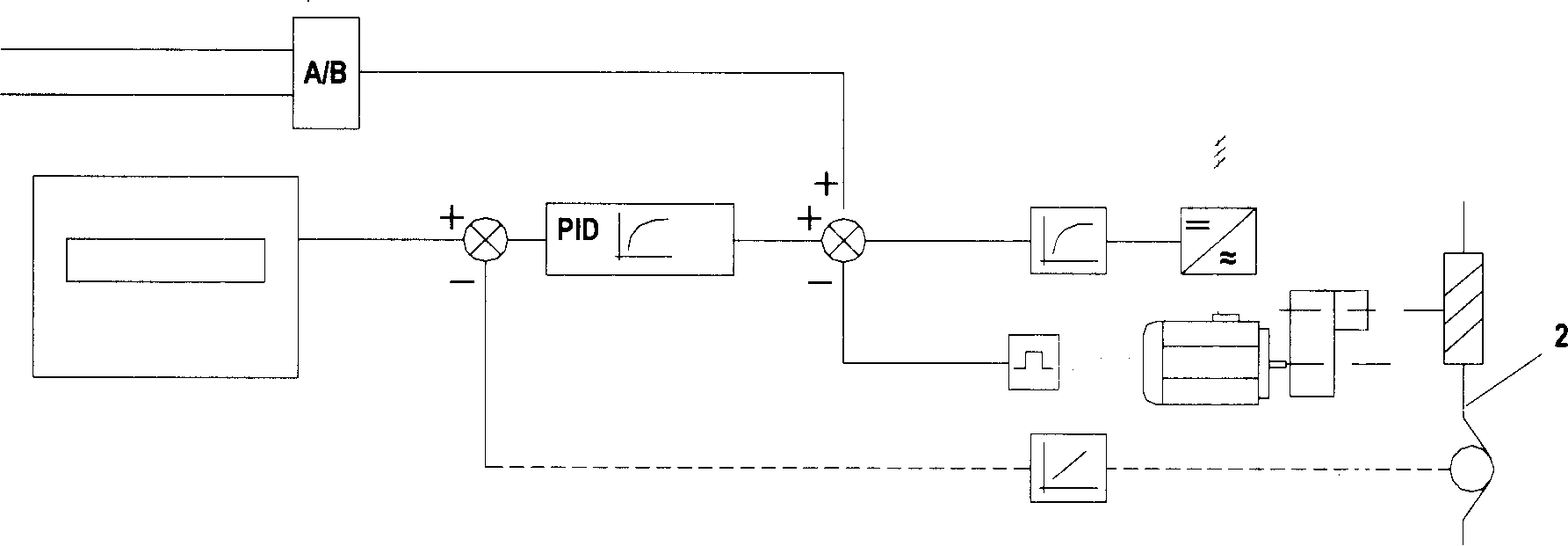

[0028] Such as figure 1 Shown is a specific embodiment of the film tension control method of the present invention, comprising the following steps:

[0029] First, in film production, a film production system including at least unwinding, tape, winding and tension controller, and servo drive device is established; floating roller mechanism 1 is set before winding, and floating roller mechanism 1 includes floating roller 11, and The swing rod and cylinder 12 linked by the floating roller 11, the floating roller potentiometer 13;

[0030] Thereafter, according to the preset cylinder pressure, the tension on the material belt 2 and the force of the cylinder 12 are kept in balance, so that the floating roller 11 is in the central position.

[0031] When the tension changes, the position of the floating roller 11 will rise or fall, and the pendulum will rotate to drive the floating roller potentiometer 13 to rotate together. The floating roller potentiometer 13 detects the positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com