Repeatedly-usable elevator apparatus

A technology of lifting device and pile fixing frame, which is applied in water conservancy projects, artificial islands, underwater structures, etc., can solve the problems of long construction time, sudden broken teeth of gears or racks, and difficulty in inserting and pulling pins, so as to save marine life. Construction time and construction cost, good economic and social benefits, and the effect of improving safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

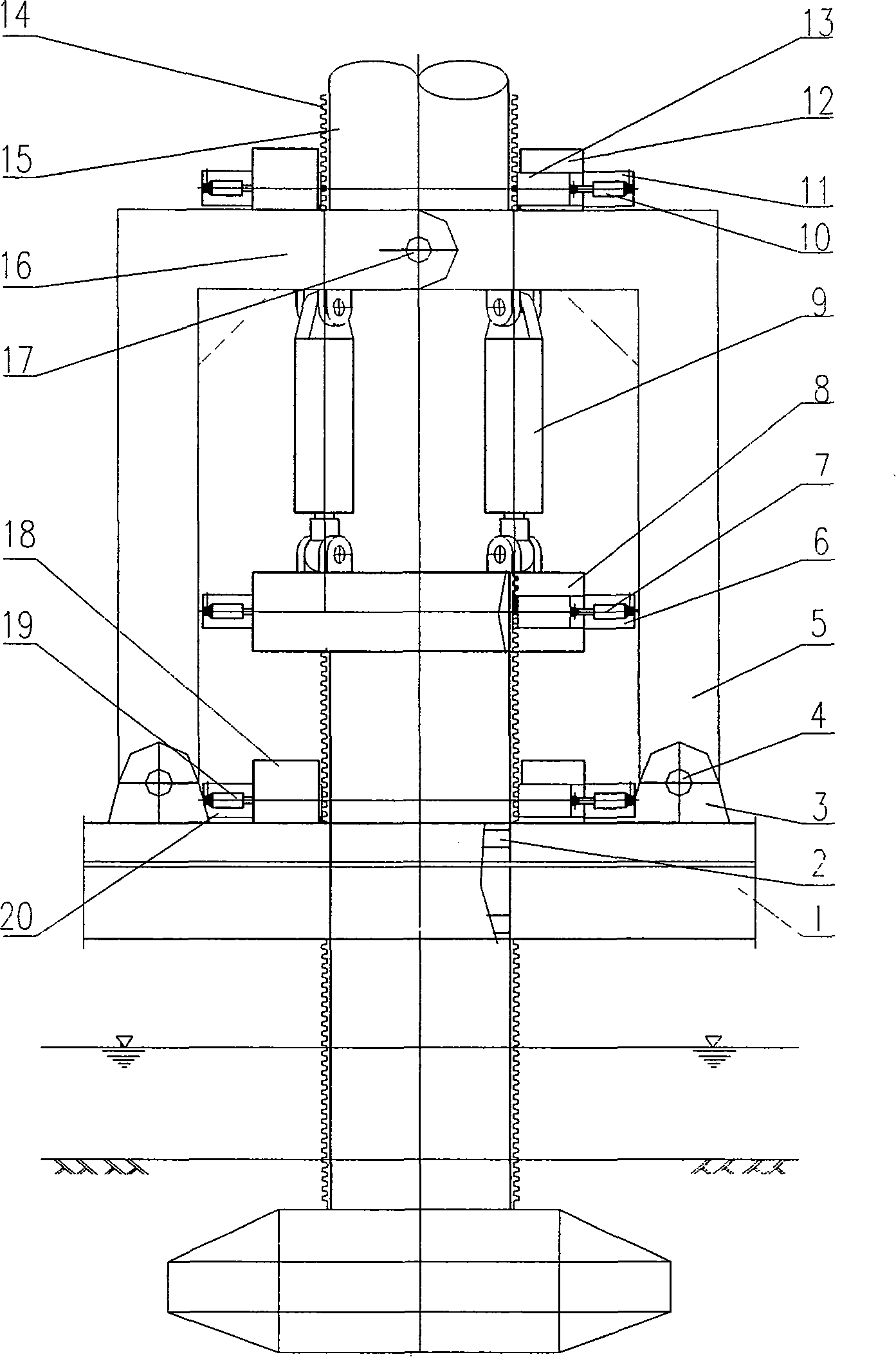

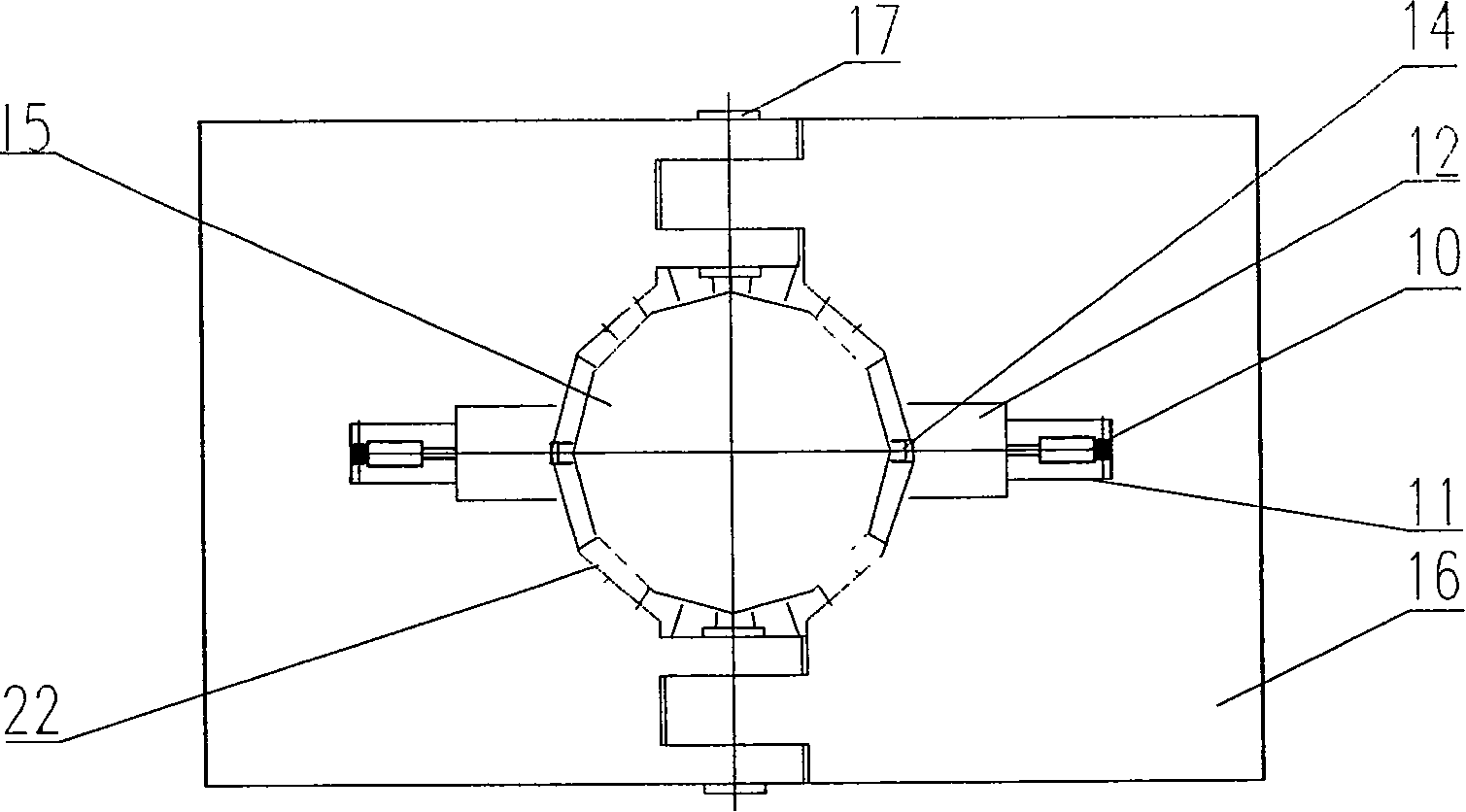

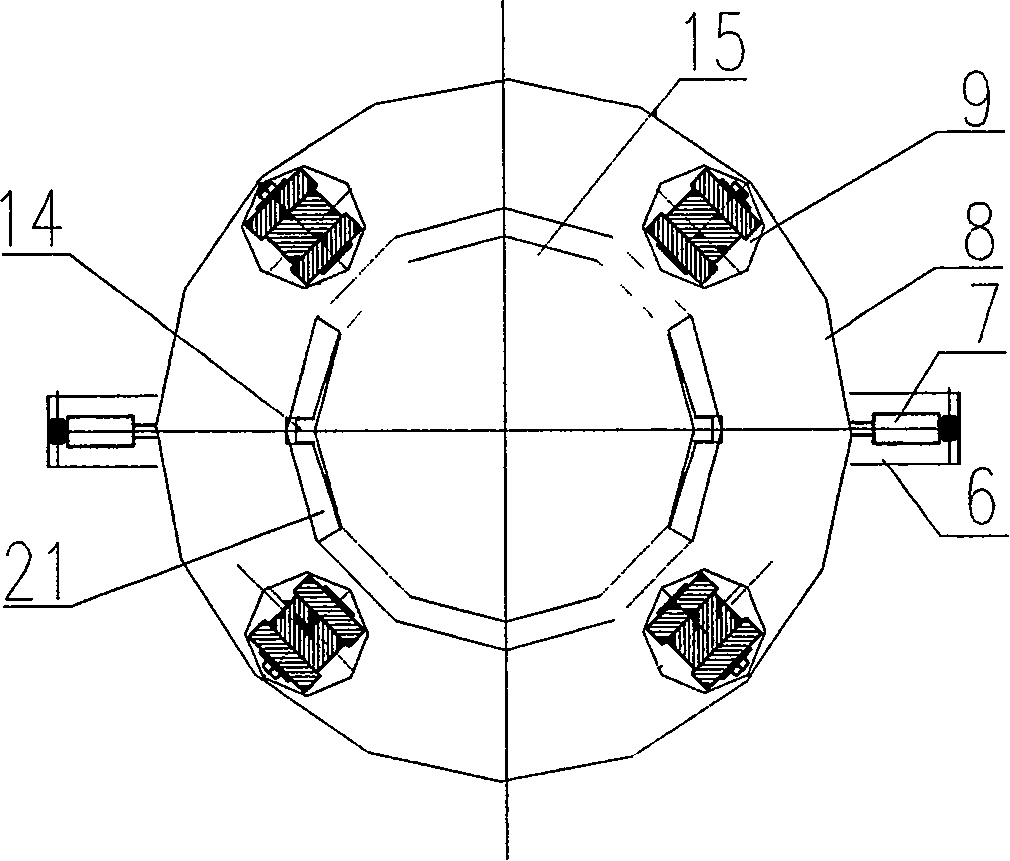

[0025] Now combined with the manual figure 1 , 2 , 3, the present invention is further described:

[0026] Lifting device platform body 1, guide ring 2, platform connecting body 3, platform connecting pin 4, movable pile fixing frame 5, ring beam plug-in cylinder bracket 6, ring beam plug-in cylinder 7, ring beam 8, lifting cylinder 9 , Upper row plug-in oil cylinder 10, upper row plug-in oil cylinder bracket 11, upper row tooth block connector 12, tooth block 13, rack 14, pile leg 15, square beam 16, pile fixing frame connecting pin 17, lower row Tooth block connecting body 18, lower row plug-in oil cylinder 19, lower row plug-in oil cylinder bracket 20, ring beam guide block 21, solid pile block 22 form.

[0027] The function of the lifting device is to connect the platform with the legs to form a force transmission. There are three force transmission methods: (1), the platform body 1 is integrated with the movable pile fixing frame 5 through the platform connecting body ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com