Assembled indoor stepless decorative wall

An assembled, decorative wall technology, applied in covering/lining, construction, building structure, etc., can solve the problems of noise, site cost loss, hindering new social needs, etc., to achieve the effect of easy installation and quick disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

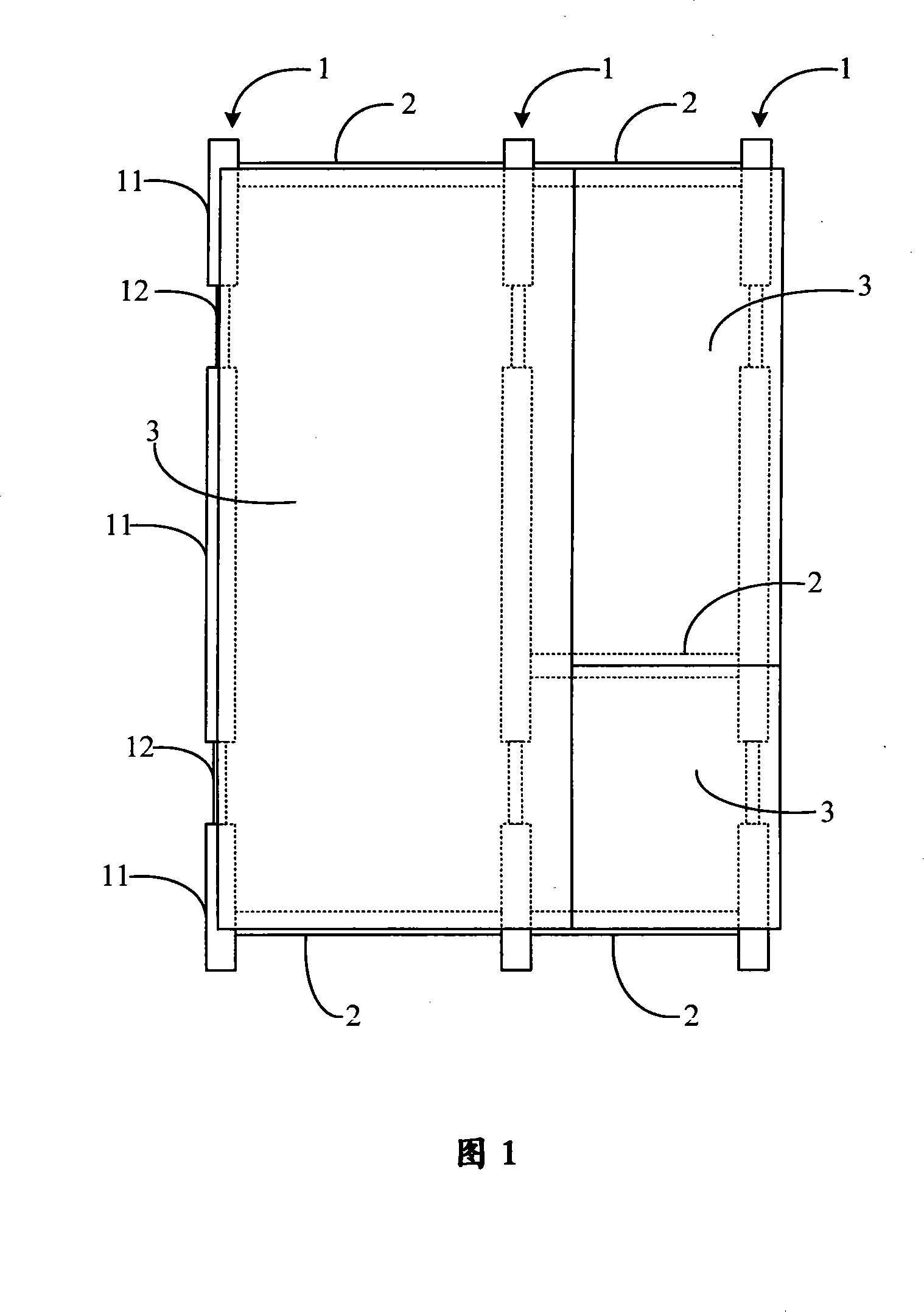

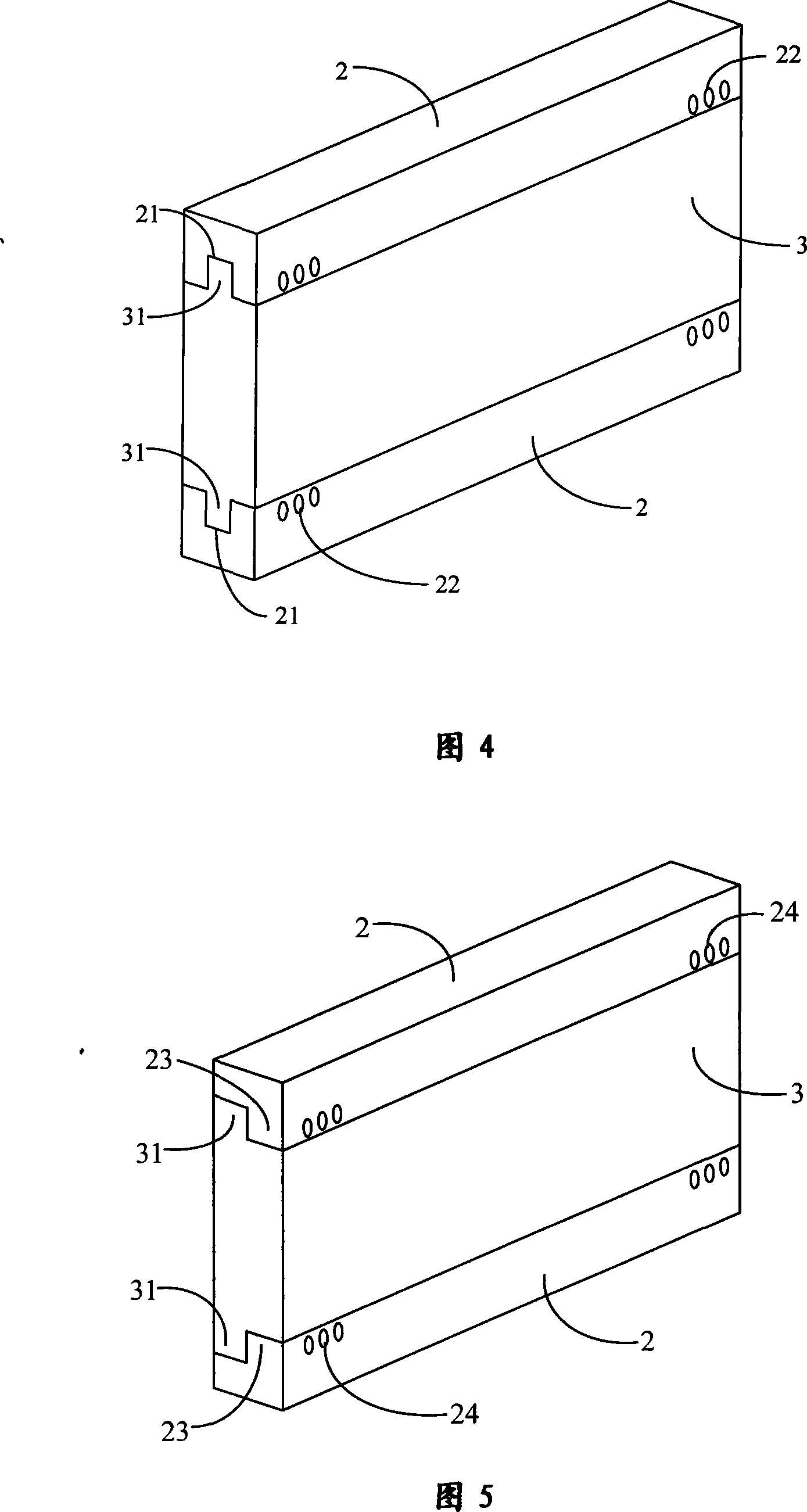

[0052] Figure 1 shows the basic structure of an indoor stepless decorative wall panel of the present invention, including a support body composed of three longitudinal pillars 1 and five transverse connecting rods 2 connected between the longitudinal pillars 1 . Three wall panels 3 of different sizes are installed on the support body. The longitudinal strut 1 is composed of three longitudinal unit columns 11 telescopically connected end-to-end through longitudinal connecting parts 12 . The transverse connecting rod 2 is provided with a receiving part, and the upper and lower ends of the wallboard 3 are respectively provided with mounting parts matching the receiving part. The wallboard 3 is installed on the support body through the mating connection between its installation part and the receiving part.

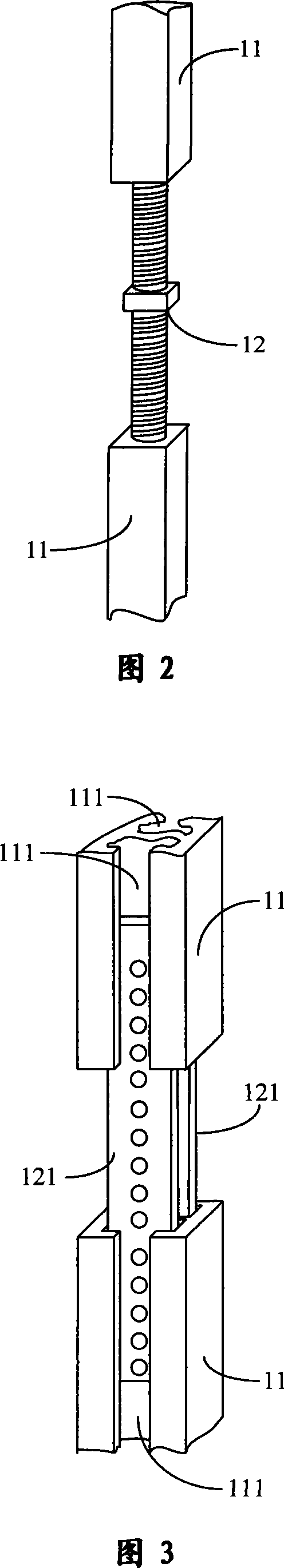

[0053] The connection structure between the longitudinal unit columns 11 is shown in FIG. 2 . The longitudinal unit column 11 is a column body with screw holes on the end su...

Embodiment 2

[0062] As shown in Figure 6, the difference between this embodiment and the above-mentioned first embodiment is that the transverse connecting rod is similar to the longitudinal column in the first embodiment, and also consists of two (or multiple) transverse unit rods 25 through the transverse The connecting parts 26 are telescopically connected from head to tail. Through this telescopic connection to form a transverse link, the height and width of the entire support body can be adjusted together, which has better adaptability to the actual size of the site.

[0063] The structure and connection mode of the transverse unit bar 25 and the transverse connecting member 26 can be completely the same as or similar to that of the longitudinal column, and will not be repeated here.

[0064]In addition, in the above two embodiments, the receiving portion provided on the transverse connecting rod, the mounting portion provided at the upper and lower ends of the wallboard, and the matc...

Embodiment 3

[0080] Fig. 21 is a partial structural schematic diagram of the third embodiment of the present invention. The difference between this embodiment and the above-mentioned embodiment is that: the surface of the gap between the upper wallboard B and the lower wallboard C is buckled with a transverse lath D, and the gap between two adjacent wallboards on the same floor The surface of the slot is buckled with longitudinal slats E.

[0081] After the overall structure of the indoor stepless decorative wall is installed, it is often necessary to install pipelines in the gaps between the wall panels, and when the transverse connecting rod is fixedly connected to the installation part of the wall panel through the receiving part, it is usually exposed Bolts and other installation parts make the wall unattractive. Moreover, because there are gaps between the wall panels, the decorative wall has the defects of ventilation, sound insulation and incompleteness. Thus, a complete closure ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com