Engine belt transmission wheel series

A belt drive and engine technology, applied in the direction of machines/engines, belts/chains/gears, mechanical equipment, etc., can solve the problem of reducing the reliability and life of belt and pulley bearings, excessive tension on one side of the belt, and fluctuations in belt tension etc. to achieve the effects of low cost, reliable operation, and reduced system tension and vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

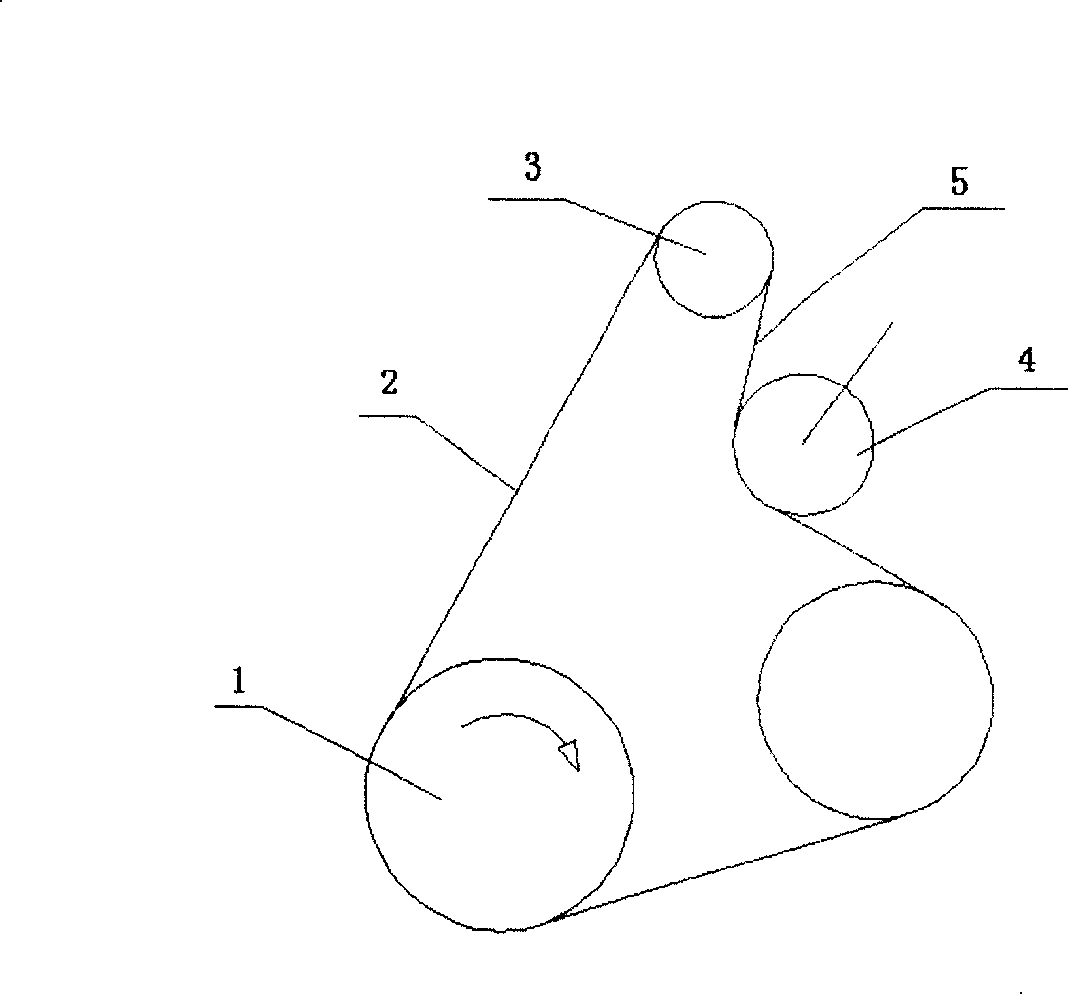

[0018] exist figure 1 Among them, an existing BSG system engine accessory belt drive wheel train, including a belt, a crankshaft pulley 1, a starter / generator 3, and a tension pulley 4. The crankshaft pulley 1 needs to drive the high-power, high-inertia starter / generator 3 of the BSG system through a belt. The usual method is to increase the tension of the system and increase the damping of the system to reduce system vibration. If a traditional mechanical tensioner 4 is used, it is necessary to increase the spring torque on the tensioner. Usually, the installation tension of the tensioner reaches 550N-650N. At the same time, increase the friction of the plastic damping sheet to improve the damping of the tensioner. The damping level of the tensioner can only reach 60% at most, and if the damping is increased, the reliability and life of the tensioner itself will be greatly reduced.

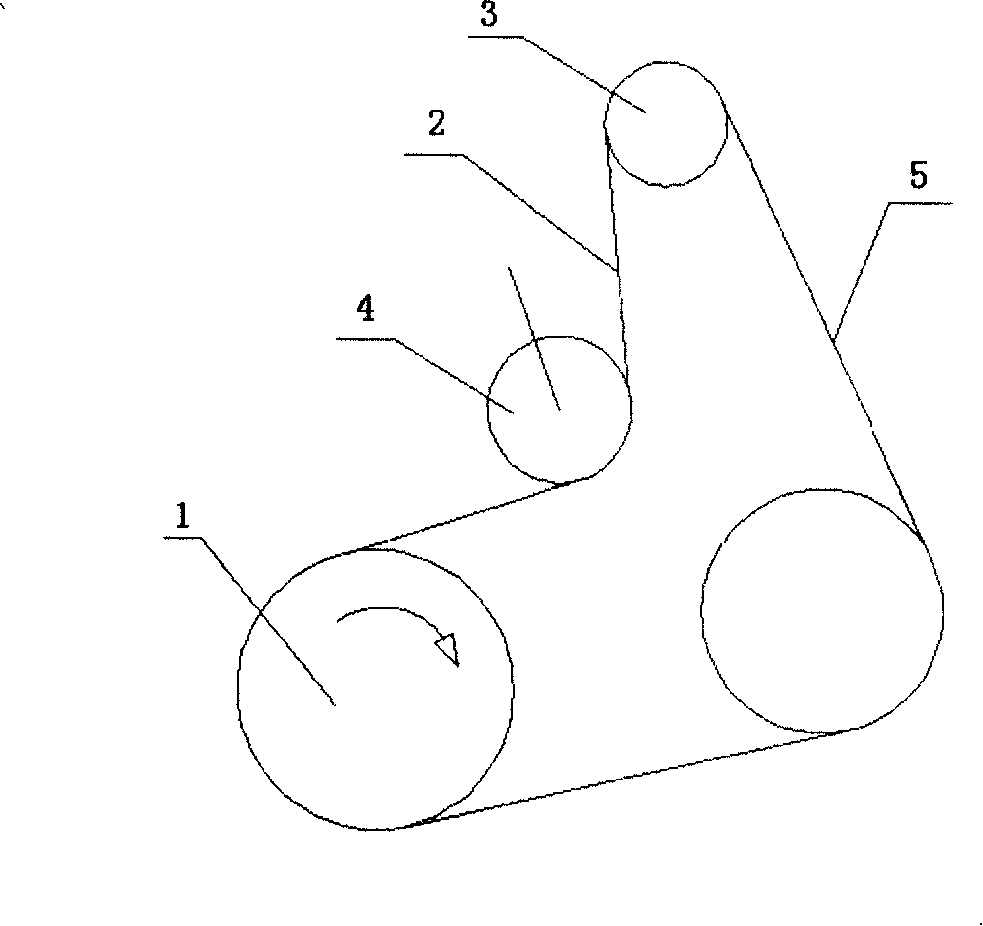

[0019] exist figure 2 Among them, another existing engine accessory belt drive train in BS...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com