Low rotor inertia dry type dual clutch

A moment of inertia and dual-clutch technology, applied in the direction of mechanically driven clutches, clutches, friction clutches, etc., can solve the problems of reduced ride comfort and handling, and difficulty in chassis matching, and achieve improved ride comfort and handling with a simple structure , reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

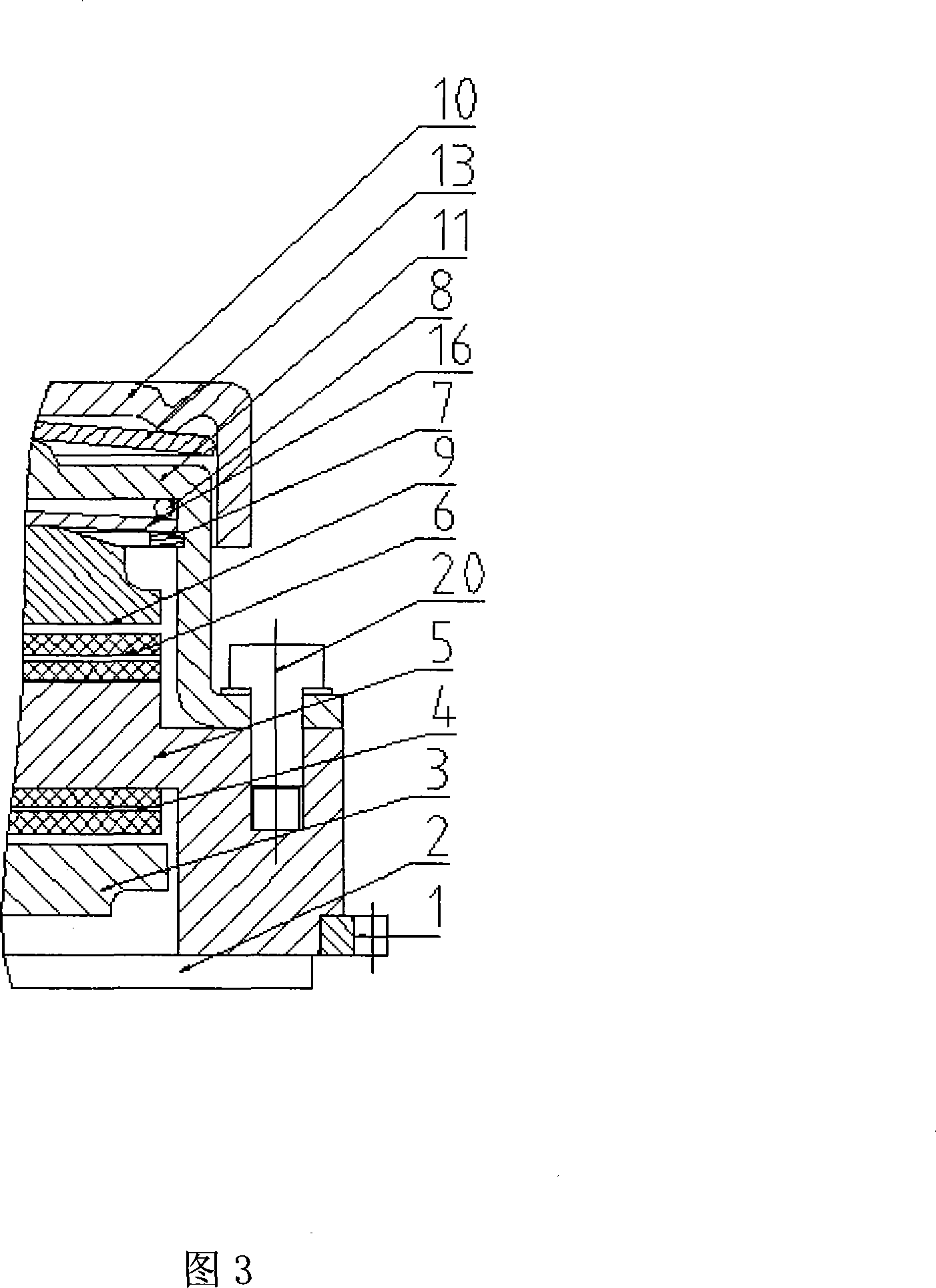

[0021] The present invention is described in detail below in conjunction with accompanying drawing:

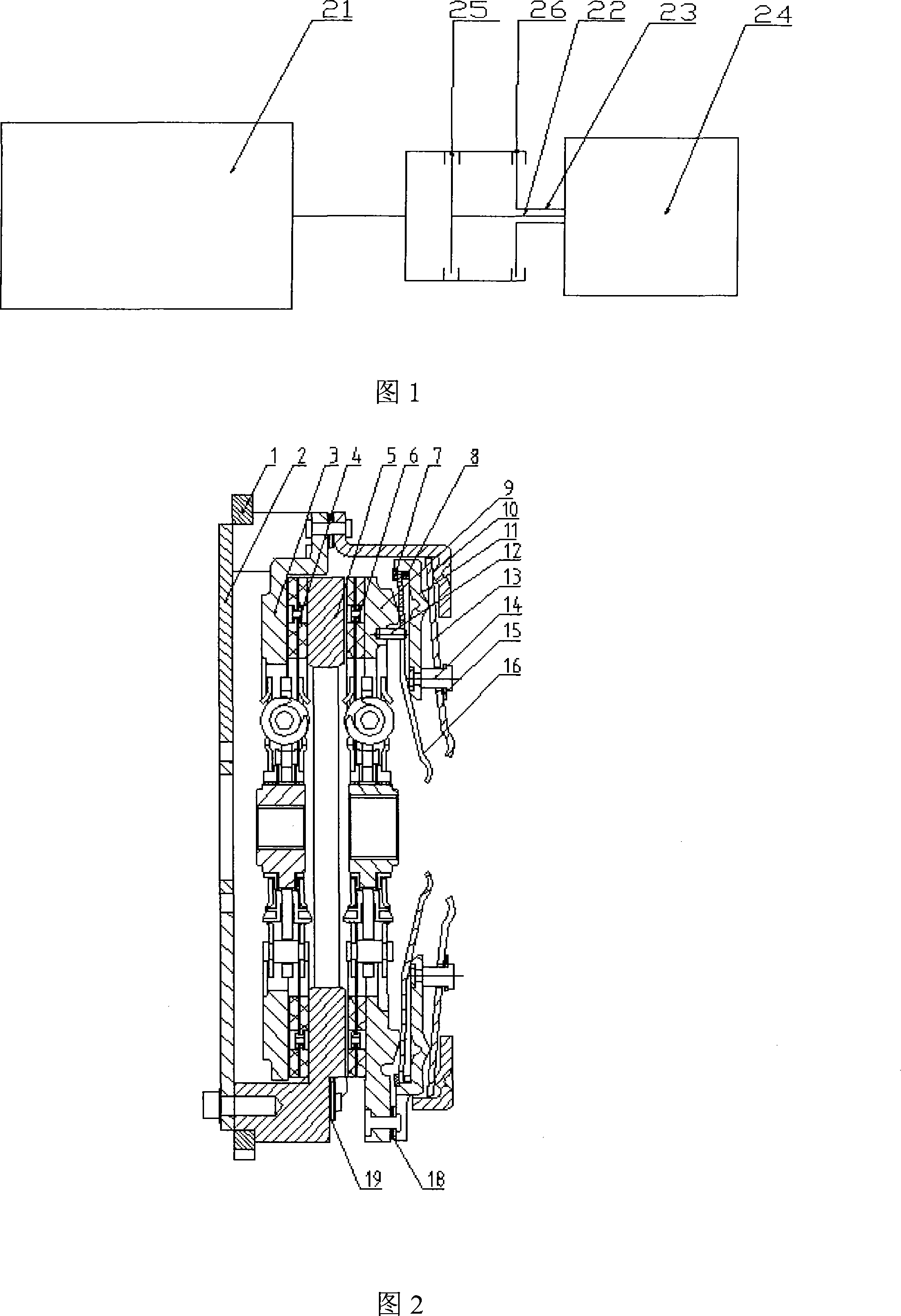

[0022] Referring to Figures 1 to 9, the low moment of inertia dry-type dual clutch, in addition to including the existing ring gear 1, I clutch driven plate assembly 4, II clutch driven plate assembly 6, calipers 7, support ring 8, In addition to II clutch pressure plate 9, II clutch housing 11, I diaphragm spring 13 and II diaphragm spring 16, it is also equipped with newly increased and improved transition plate 2, I clutch pressure plate 3, flywheel 5 and I clutch housing 10.

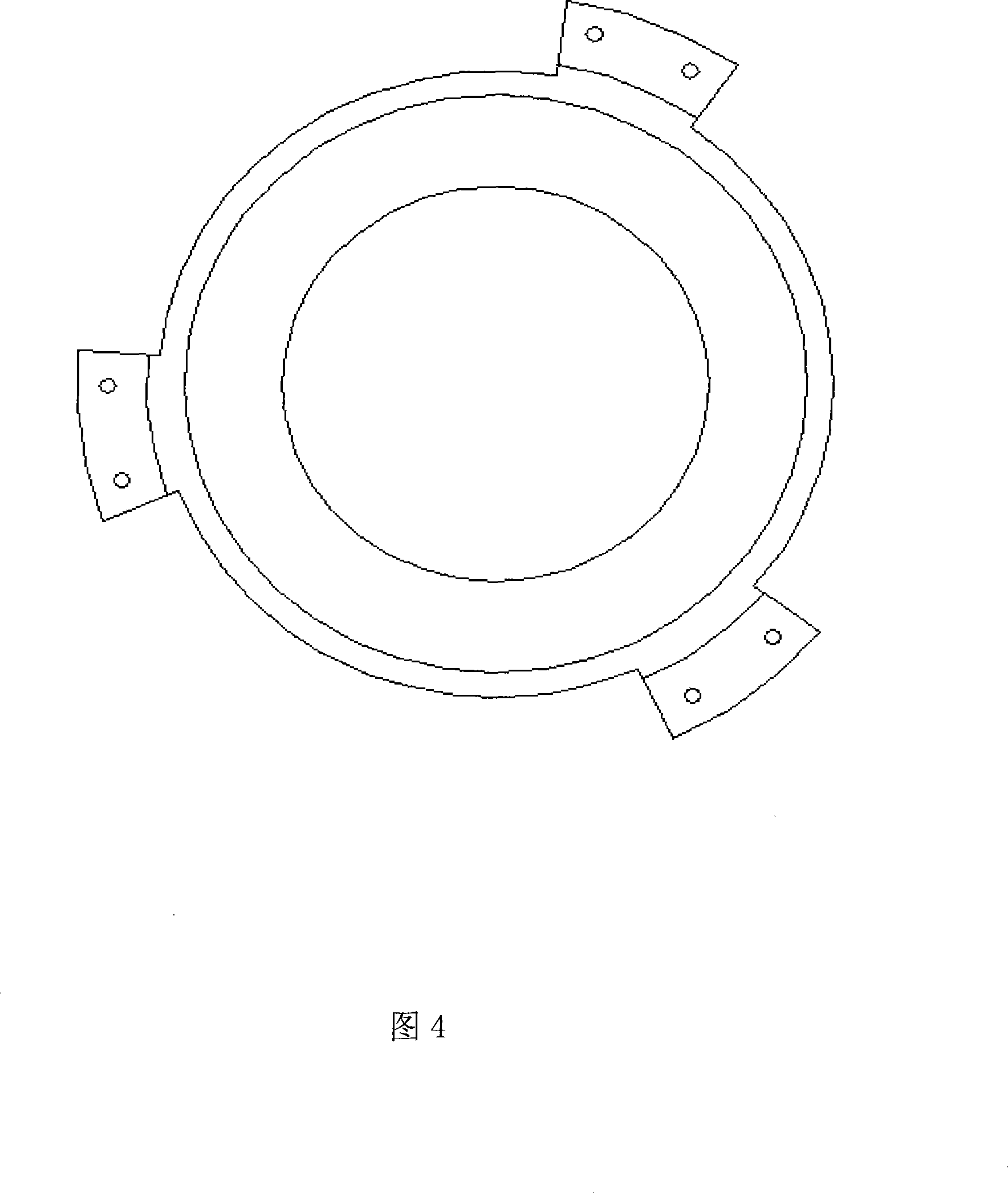

[0023] The transition plate 2 is a disc-shaped steel part, and the center is processed with a large-diameter flange through hole for the flange set on the output end of the crankshaft of the engine 21. Around the flange through hole There are 6 identical bolts (screws, rivets) through holes uniformly distributed for fixed connection with the flange plate, and 6 holes for threading screws for fixed c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com