Optical short distance amending method

An optical short-distance and distance technology, which is applied in the direction of optics, originals for photomechanical processing, and photoplate-making process on patterned surfaces, can solve the problems of restricting the development of advanced lithography process and the deterioration of imaging results, and achieve improved Effect of graphics resolution and DOF

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

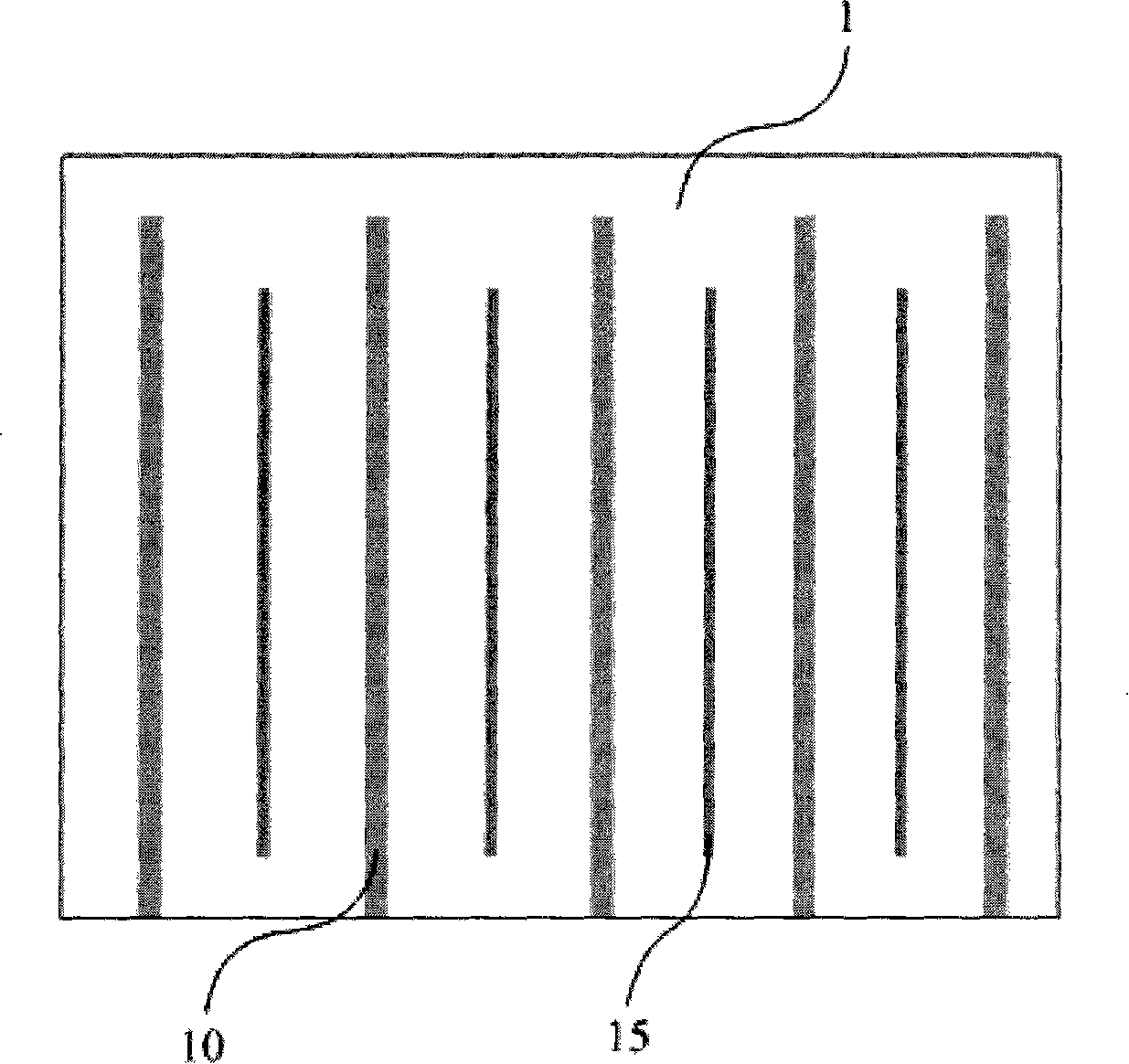

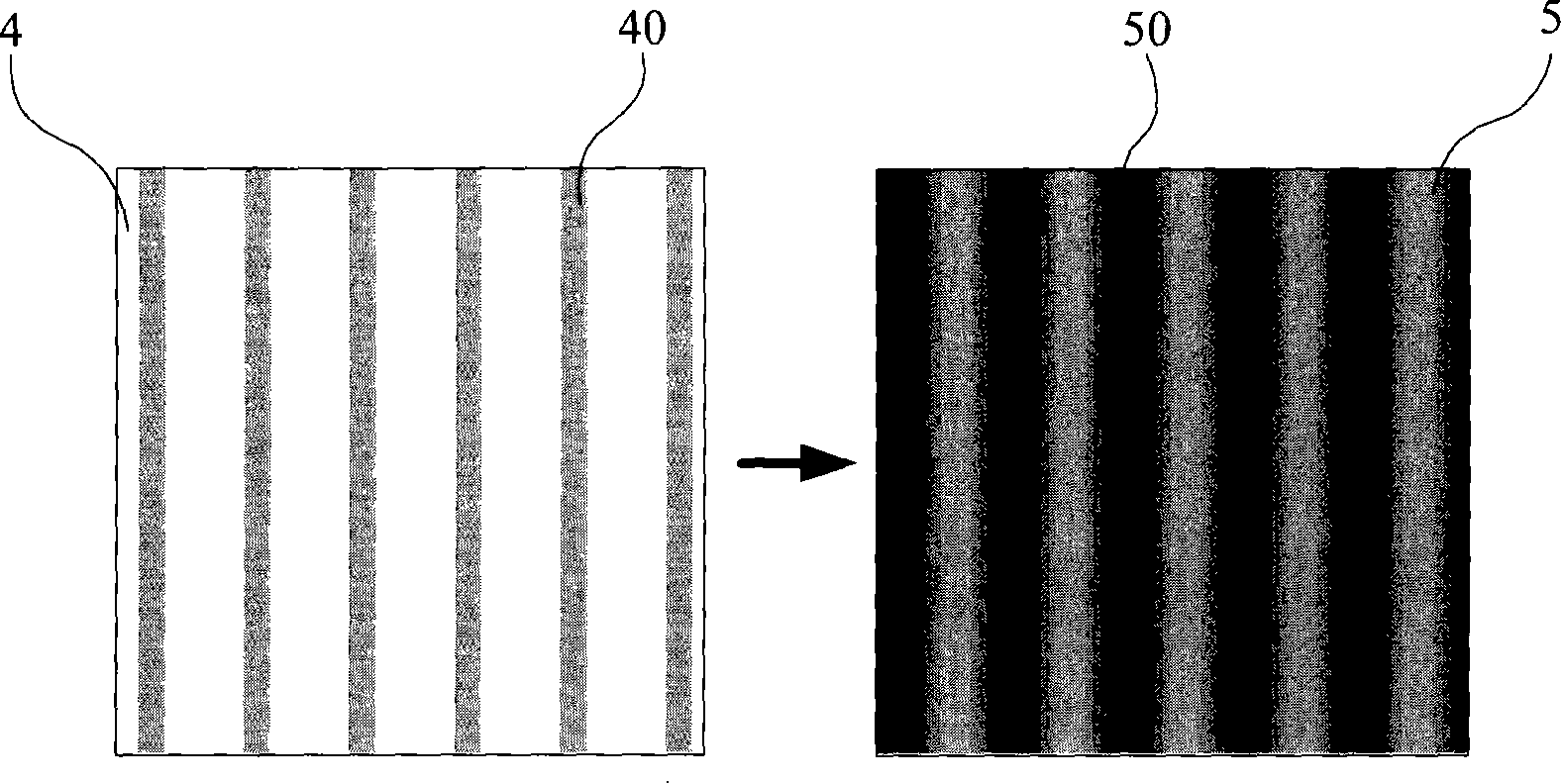

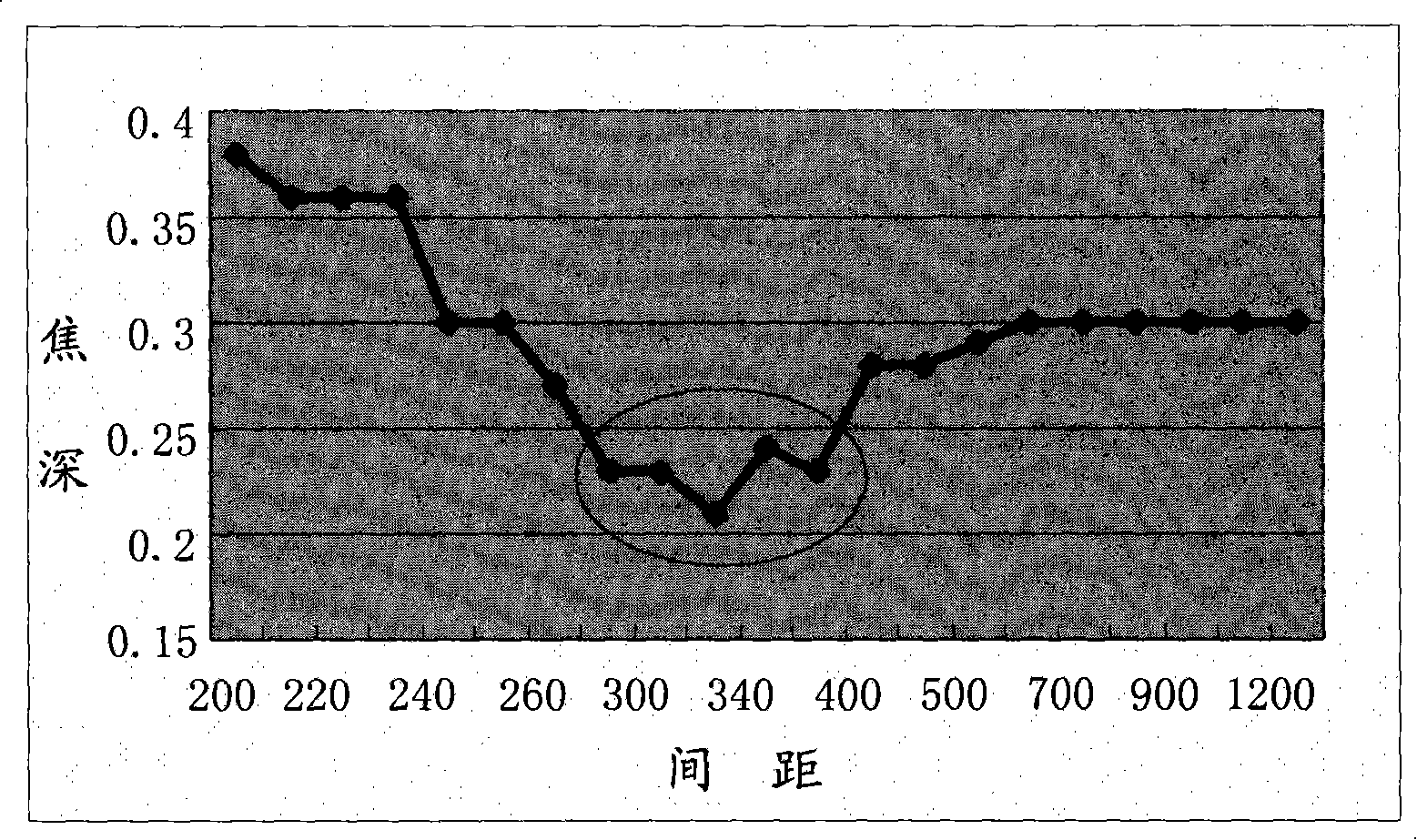

[0023] As integrated circuits contain more and more devices, the size and spacing of individual devices are required to be smaller and smaller. Starting from 0.13 micron products, the optical proximity effect becomes significant, and the optical proximity effect originates from the interference between light scattered on adjacent patterns. Representative optical proximity effects include reduced line width, shortened line ends, and square corner passivation in the forbidden pitch range, which are caused by the decrease of DOF and the increase of MEEF in the forbidden pitch range. of. For processes of 0.13 microns and above, optical proximity correction, including dense and sparse line width balance, line end stability, and square corners plus decorative edges, is sufficient to meet the requirements for line width uniformity. For 0.13 micron and below processes, more complex model-based optical proximity correction becomes indispensable because it can use calibrated optical mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com