One-way power output minitype speed reducing motor

A technology of miniature gear motor and power output, which is applied in the direction of electrical components, electromechanical devices, electric components, etc., to achieve the effects of unique structure, expanded application range, and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

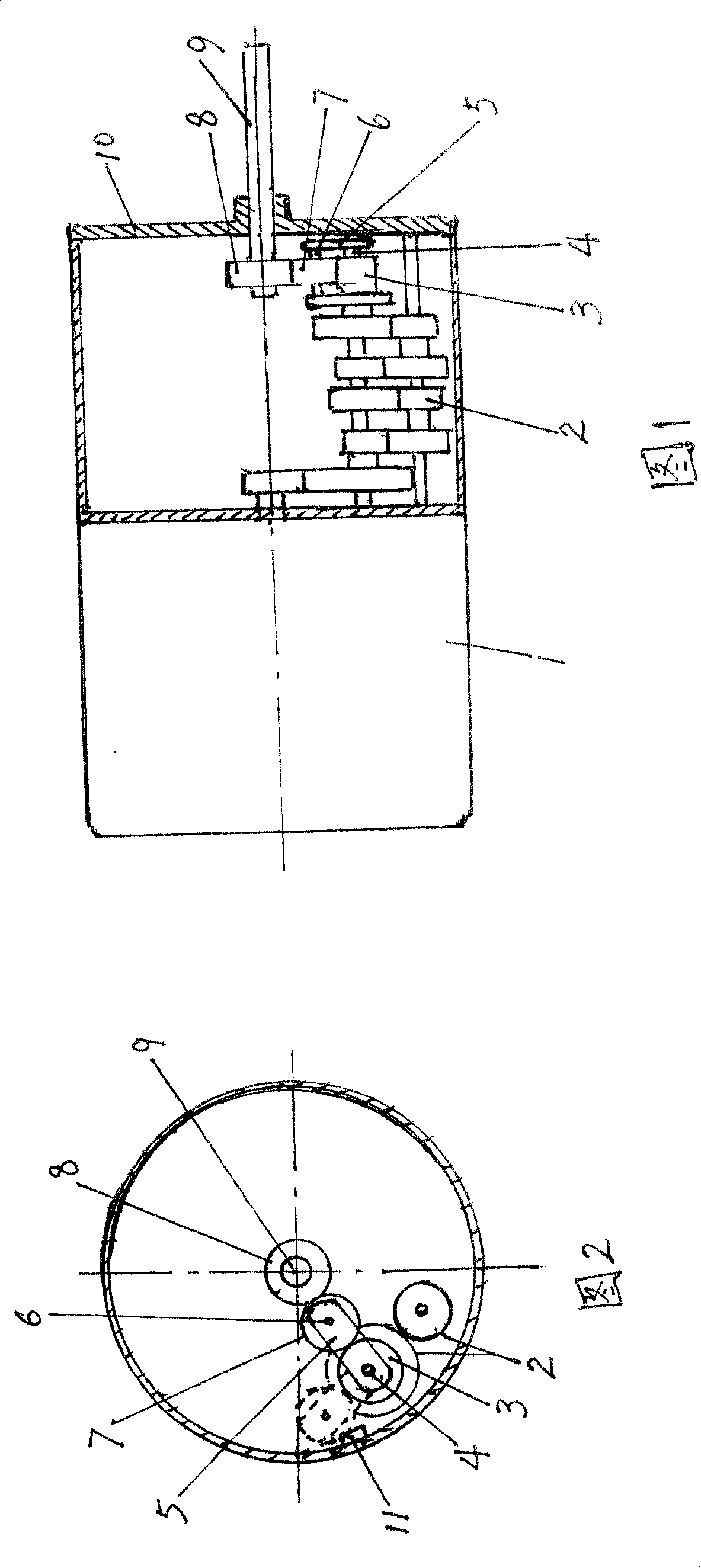

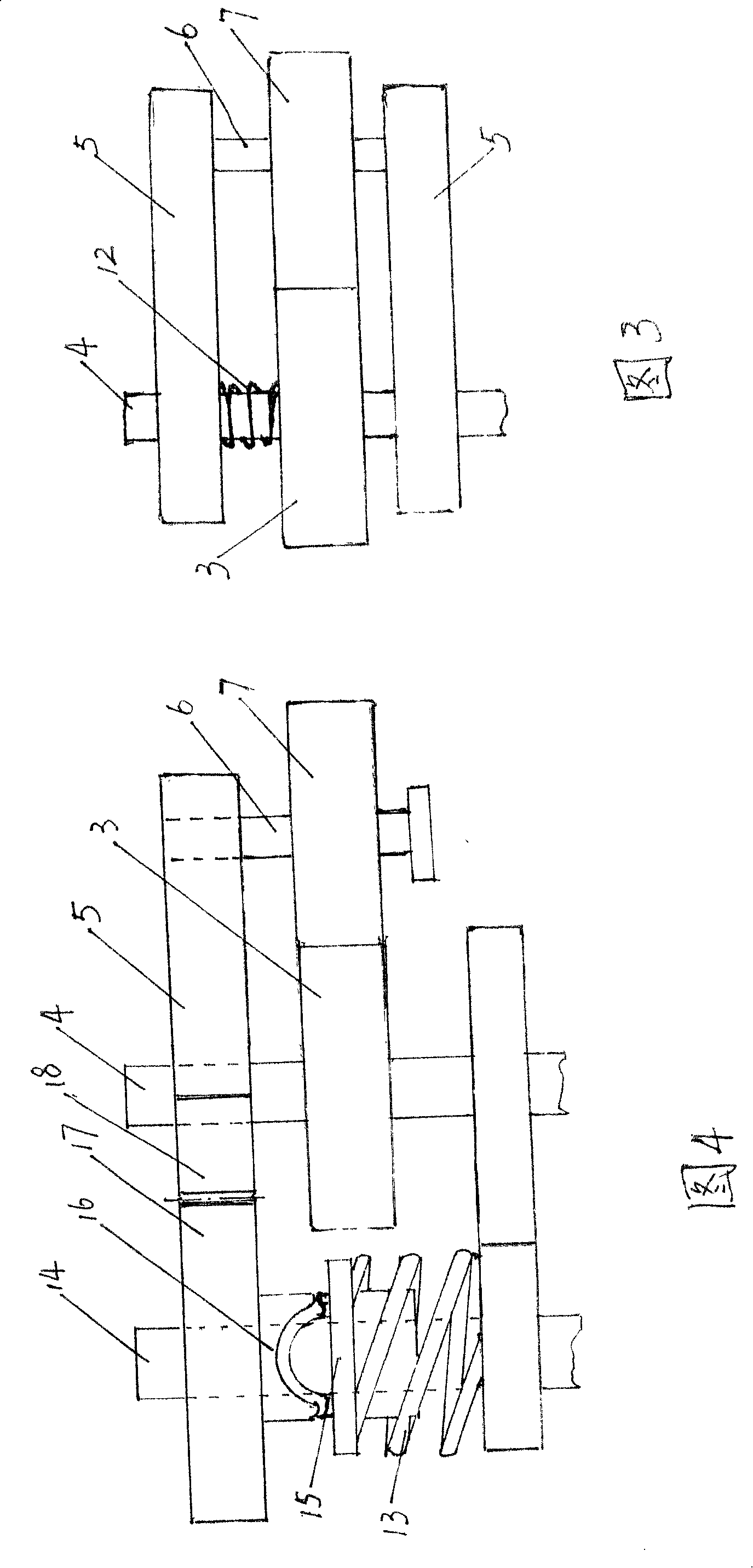

[0017] Referring to Fig. 1 and Fig. 2, the present invention has the basic structure of an ordinary geared motor, including a motor 1 and a reducer 2 connected with the motor, the front end cover 10 of the reducer 2 is equipped with an output shaft 9, and the tail end of the output shaft 9 Transmission gear 8 is fixedly installed. In particular, the following ingenious improvements are made in the present invention: a transition gear 7 is added between the final gear 3 of the reducer and the gear 8 at the tail end of the output shaft, and the transition gear 7 passes through the shaft 6 (move fit assembly) , is installed on the swivel arm 5, and swivel arm 5 can be single arm, is better to make upper and lower double-arm structure (seeing figure 1). The tail end of the rotating arm 5 is rotationally connected with the spindle 4 of the speed reducer. The tail end of the rotating arm 5 can also be rotationally connected with the front end cover 10 of the speed reducer 2 by usin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com