A kind of preparation method of nylon 12 composite material

A composite material and nylon technology, applied in the field of preparation and modification of high-viscosity nylon 12, to achieve the effect of improving impact performance, increasing strength and reducing material cost

Inactive Publication Date: 2011-12-21

SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

View PDF6 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004]However, these methods are complicated in process, long in process, low in efficiency, and some have pollution

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

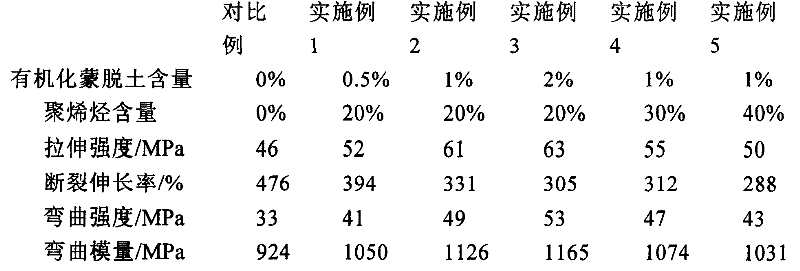

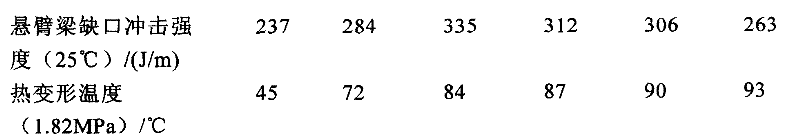

Embodiment 1

[0024] Example 3

Embodiment 2

[0026] Example 4

Embodiment 3

[0028] Example 5

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The present invention involves a preparation method for a new type of nylon 12 composite materials. This method includes the following process steps: (1) add 20 to 40WT % of polyolefins to the melted nylon 12 monomer, disperse by stirring, (2)Diversify the 0.5 ~ 2WT % of the melted nylon 12 monomer, (3) mix the above two, add 0.5 to 2WT % cause and 0.5 ~ 2WT % to help the catalyst, and open the anion of the monomer to openRing aggregation to obtain composite materials.Compared with existing technology, the present invention has the characteristics of simple craftsmanship, short process, high efficiency, and no pollution.

Description

technical field [0001] The invention relates to a method for modifying nylon 12 with montmorillonite and polyolefin, especially the preparation and modification method of high-viscosity nylon 12. Background technique [0002] Nylon 12 (PA12) has low water absorption, good low temperature resistance, good air tightness, excellent alkali resistance and grease resistance, medium resistance to alcohols, inorganic dilute acids and aromatic hydrocarbons, good mechanical properties and electrical properties, and is a natural extinguishing material. At present, it is widely used in fuel pipes and brake pipes, optical fiber sheaths, photoelectric fiber coatings, sports equipment and food packaging in automobiles. However, due to the high cost of nylon 12 compared with the largest amount of nylon 6 and 66, its application range is seriously affected. How to reduce the cost on the basis of maintaining the mechanical properties of nylon 12 is an important problem facing the expansion...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B29C47/92C08G69/18C08G69/16C08L77/00B29C47/40C08L23/00B29C48/40B29C48/92

CPCB29C48/92B29C2948/92704B29C48/40B29C2948/92885

Inventor 杜立波杨桂生

Owner SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com