Cotton imitation polyester filament yarn fabric and preparation method thereof

A technology of polyester filament and filament fabric, applied in the direction of fabric, textile, textile and paper making, can solve the problems of poor hairiness stability, poor hygroscopic performance, weakened cotton feeling, etc., and achieve the effect of excellent hygroscopic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

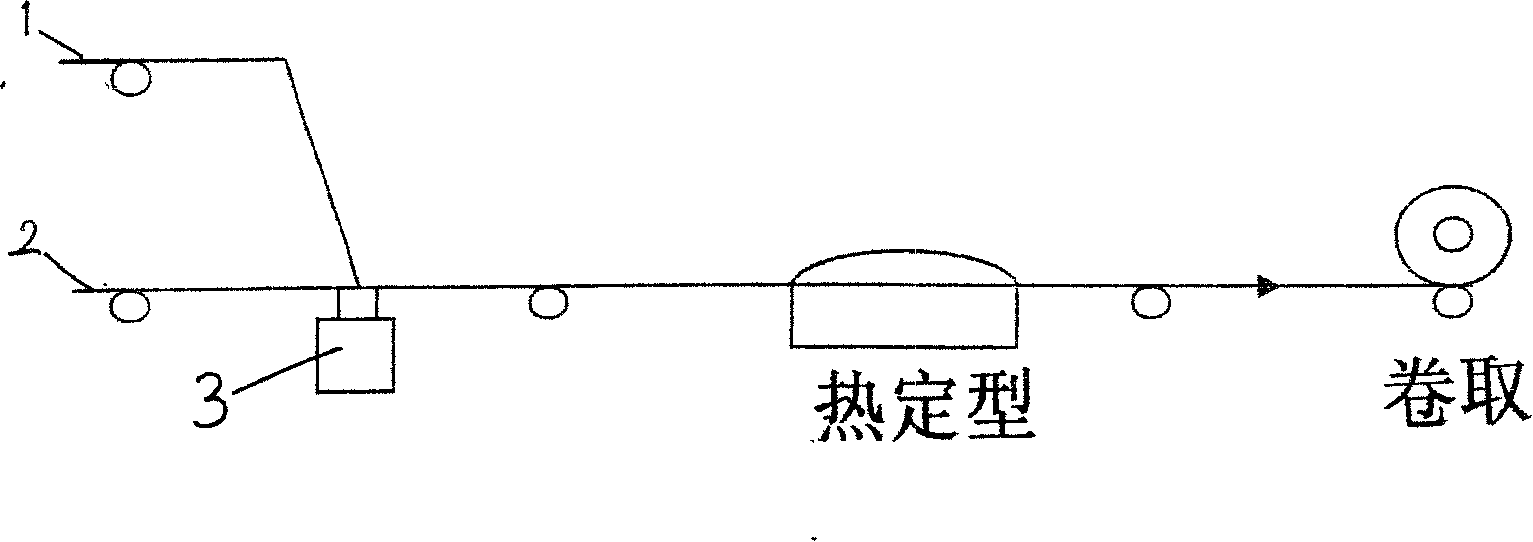

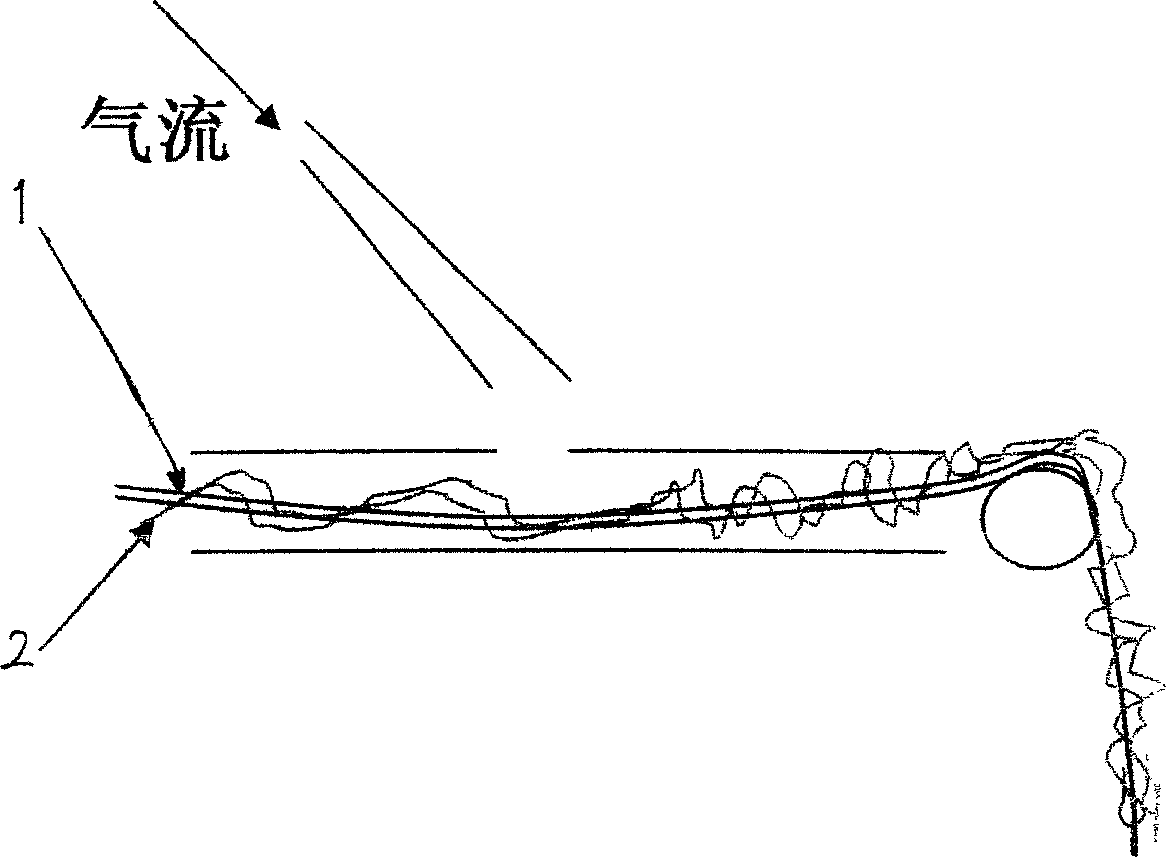

[0016] A cotton-like polyester filament fabric, the cotton-like polyester filament used is 215T / 168 composite yarn, the raw yarn selected during processing: decorative yarn 2 is pre-oriented yarn 133T-144-POY, core yarn 1 It is a fully drawn yarn 75T-24-FDY, the filament length difference between the core yarn and the decorative yarn is 5%, the monofilament fineness of the decorative yarn is 0.8D / F, and the core yarn monofilament fineness is 2.8D / F, pre-oriented The silk accounts for 64% of the weight of the entire cotton-like polyester filament, and the fully drawn yarn accounts for 36% of the weight of the entire cotton-like polyester filament. The core yarn and decorative yarn are fed into the air texturing nozzle (TASLAN) 3, and they are deformed by the action of air flow; then the cotton-like polyester filament 215T / 168 composite yarn is used as the warp yarn, and the weft yarn is 150D elastic yarn. 5 satin patterns on the surface of 2 flying warps, the density of warp and we...

Embodiment 2

[0024] A cotton-like polyester filament twill fabric. The cotton-like polyester filament used is the same as that in Example 1. The warp and weft yarns are all cotton-like polyester filament, the weave is 2 / 2 twill, and the warp and weft density is 170 threads / inch× 56 pieces / inch, the grey fabric is refined → dried → intermediate shaping → continuous alkali weight reduction → dyeing and moisture absorption → resin → finishing and shaping to make a product. The weight of cotton-like polyester filament yarn in the fabric accounts for 100% of the weight of the entire fabric. The product is light in weight, wear-resistant, easy to wash, and has a rich, delicate and soft appearance and feel similar to cotton fabrics and excellent moisture absorption properties.

[0025] Key engineering conditions:

[0026] Weight reduction: the concentration of caustic soda is 35%, the residence time is 10MIN, the weight reduction rate is 16.6%, V cloth=40M / MIN;

[0027] Dyeing: 135℃×35MIN, dosage of ...

Embodiment 3

[0031] First, make cotton-like polyester filaments, and then use cotton-like polyester filaments as at least one of warp and weft to make grey fabrics. The grey fabrics are subjected to post-treatments including continuous alkali weight reduction, dyeing and moisture absorption, finishing and shaping steps. The product is produced; when the cotton-like polyester filament is manufactured, the decorative yarn with the yarn type of pre-oriented yarn and the core yarn with the yarn type of fully drawn yarn are fed into the air deformation nozzle and deformed by the action of airflow; The difference in filament length between the core yarn and the decorative yarn is 2%-10% (example 2%, 6%, 10%), and the core yarn monofilament fineness is 0.5D / F~2.0D / F (example 0.5D / F) , 1D / F, 2.0D / F). Pre-oriented yarns account for 55 to 70% of the weight of the entire cotton-like polyester filament (Example 55%, 65%, 70%), and fully drawn yarns account for 30-45% of the weight of the entire cotton-lik...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com