Method for repairing damage of underwater concrete panel slope protection

An underwater concrete and repair method technology, which is applied in the repair of basic structures, excavation, coastline protection, etc., can solve the problems of difficult to understand the cause and degree of damage of underwater concrete slope protection, poor structural reliability, and damage to concrete slope protection, etc., to achieve Good bleeding and anti-dispersion properties, less work, and less work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

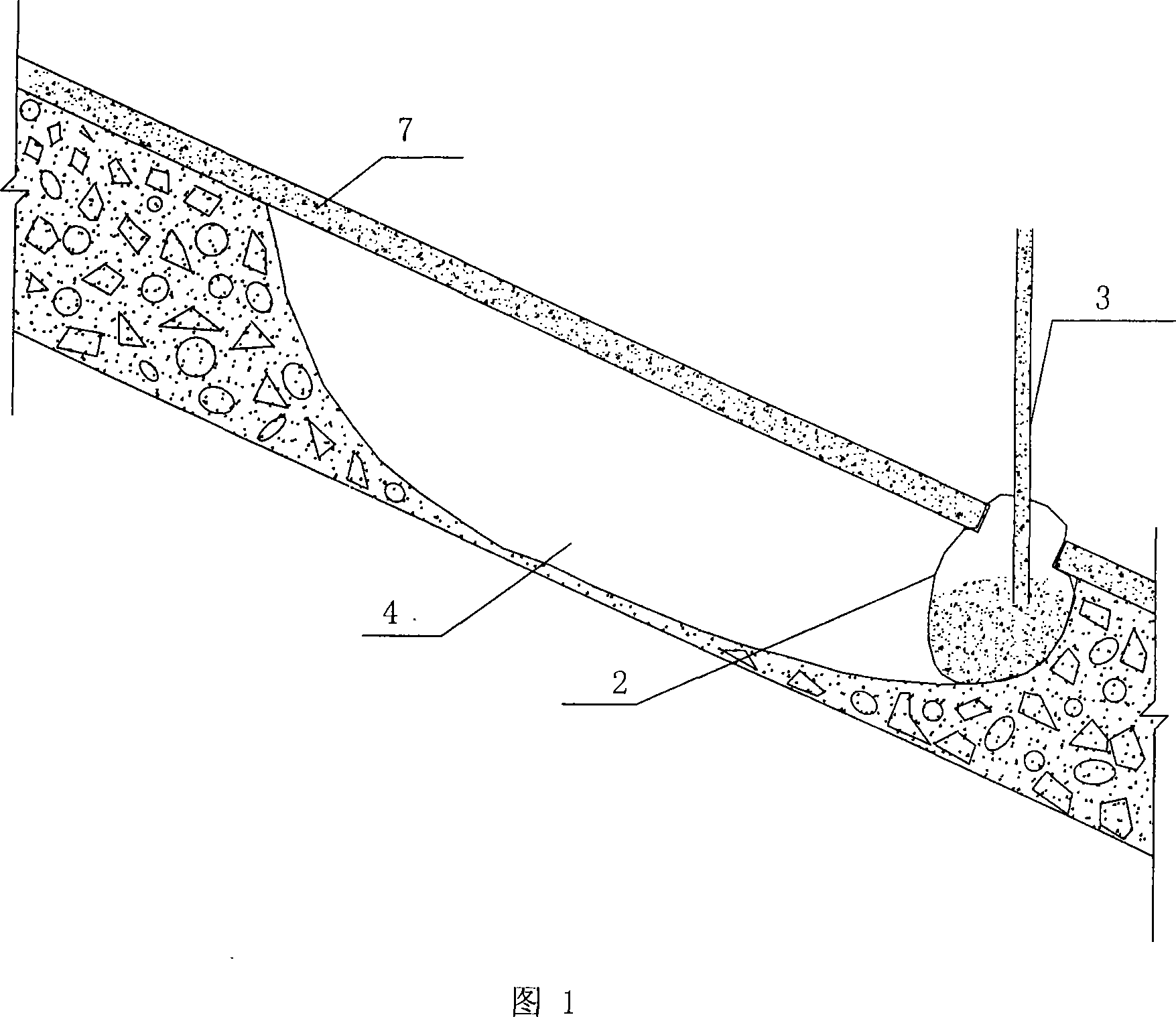

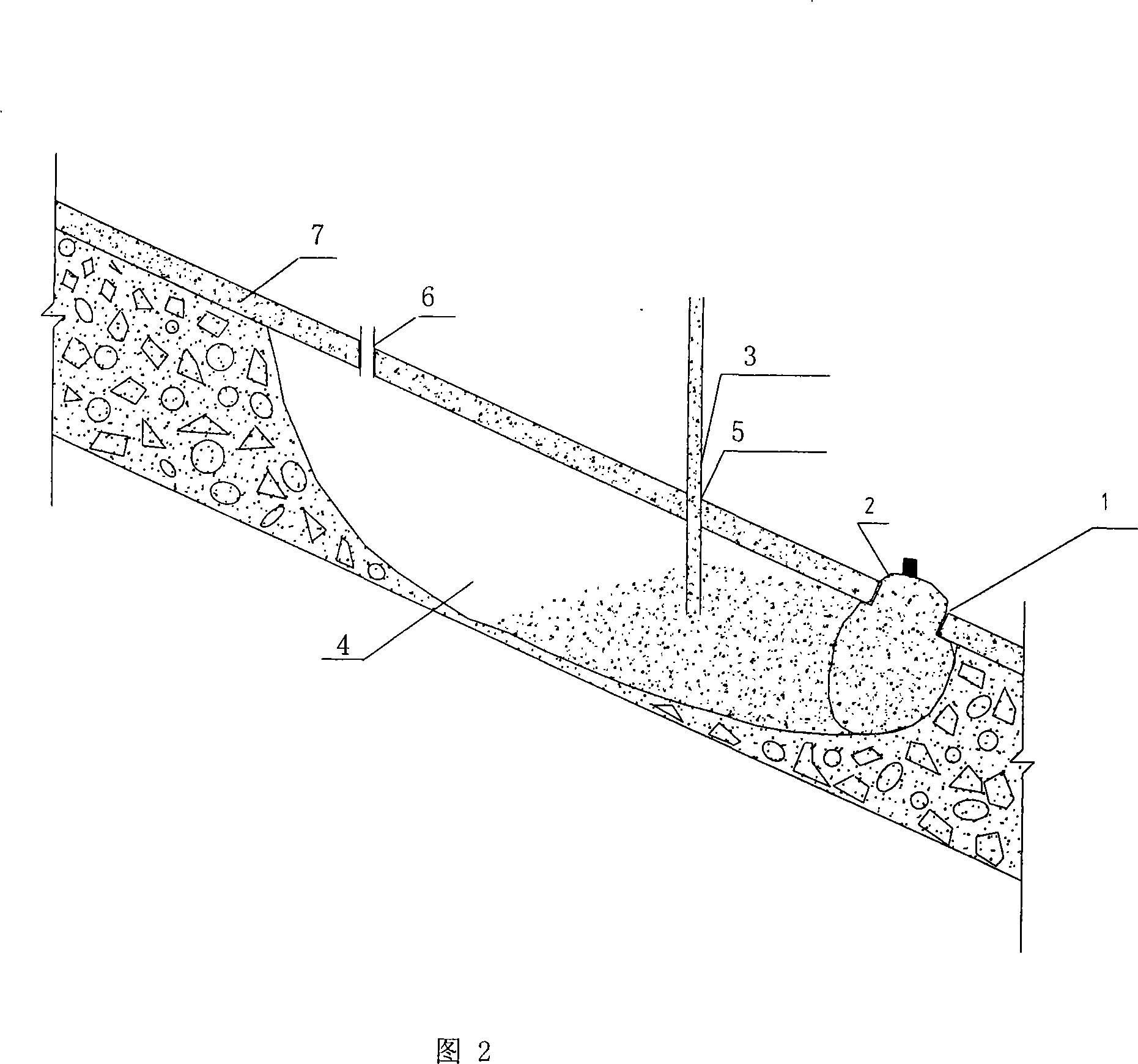

[0010] Example: Local damage repair of concrete slope protection in the 5.3-5.55km section of the upper right bank of the Gezhouba Sanjiang Channel (left side of the anti-silting embankment). The thickness of the concrete slope protection varies from 0.3 to 0.6m, the slope ratios are 1:3, 1:4, and 1:5, and the elevation of the dike crest is 70m.

[0011] First, clean up the sundries and silt accumulated at the damaged opening 1 of the concrete panel slope protection 7, remove the broken concrete block, and allow the damaged opening 1 to appear completely. Then according to the size and shape of the damaged opening 1, the periphery is made into a plugging die bag 2 that is greater than the damaged opening 150mm, and the thickness is substantially equal to the damaged opening depth. Then carry out the positioning of the mold bag 2. When the mold bag 2 is lowered, the diver first fixes its periphery. Before fixing, the positioning must be carried out according to the measurement ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com