Vacuum flat solar energy heat collector

A flat-panel solar energy and heat collection device technology, applied in the field of solar energy applications, can solve the problems of being only on the roof, difficult to maintain, and limited use, and achieve the effects of reducing brackets, reducing cost, and reducing heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

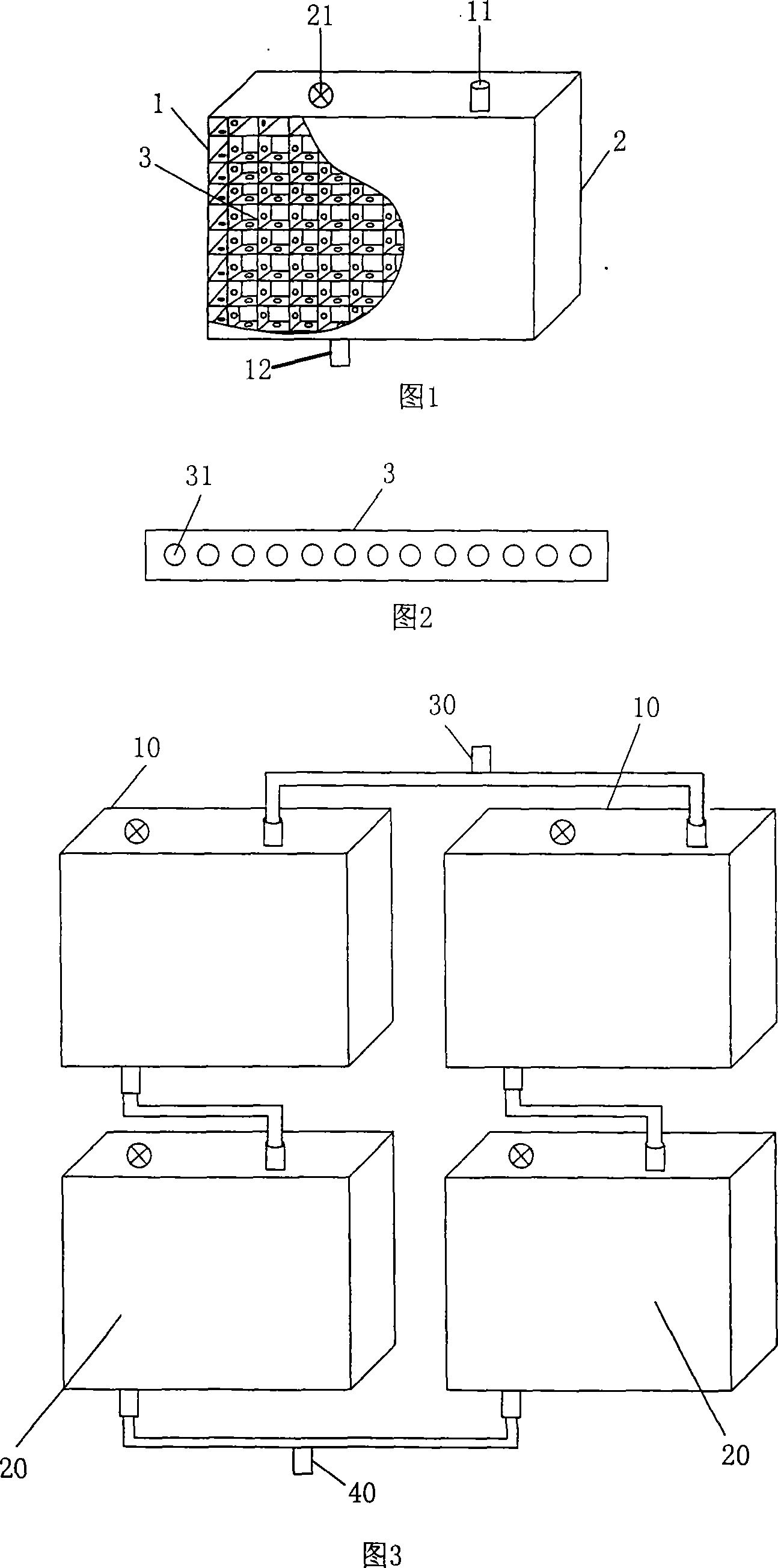

[0031] The vacuum flat panel solar heat collector of this embodiment is a structure of a single heat collector, as shown in Figure 1, it is composed of two flat inner boxes 1 and outer boxes 2 that are nested together. The square grid network formed by grid rib sheet 3 is used to connect between them. The grid rib sheet 3 is provided with a round through hole 31, so that the gap between the two boxes is connected. As shown in Figure 2, a box is set on the upper end of the outer box body. The valve 21 that can be vacuumed, through the vacuum valve, the air between the two boxes is drawn out to form a vacuum layer; the upper and lower end faces of the box are respectively provided with outlet pipe interfaces 11 and Water inlet pipe interface 12; the front panel of the outer box is made of plexiglass transparent plate, the side panels, upper and lower end panels and the rear panel are all opaque plastic plates, and each panel of the inner box is made of stainless steel. The outer...

Embodiment 2

[0036] The vacuum flat panel solar heat collector of this embodiment is a combined structure of 4 boxes, as shown in Figure 3, the structure of each box of this embodiment is the same as that of Example 1, except that the two boxes in the upper row The water inlet pipe interface of the box body 10 is connected with the water outlet pipe interfaces of the two box bodies 20 in the lower row, and the water outlet pipe interfaces of the two box bodies 10 in the upper row are connected to form a total water outlet pipe interface 30; The water inlet pipe interfaces of the box body 20 are connected to form a general water inlet pipe interface 40; forming a collector plate array.

[0037] The size of the outer box of each heat collector of the present embodiment is about 1200 mm in length, about 1000 mm in height, and about 100 mm in thickness.

[0038] The size of the inner box is about 1180 mm in length, about 980 mm in height, and about 80 mm in thickness.

[0039] The gap between...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com