Novel pipe throttling device

A throttling device and tube-type technology, which is applied in fluid circulation arrangement, high-efficiency regulation technology, lighting and heating equipment, etc., can solve problems such as poor matching of refrigerants and inability to adjust the refrigerant circulation area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

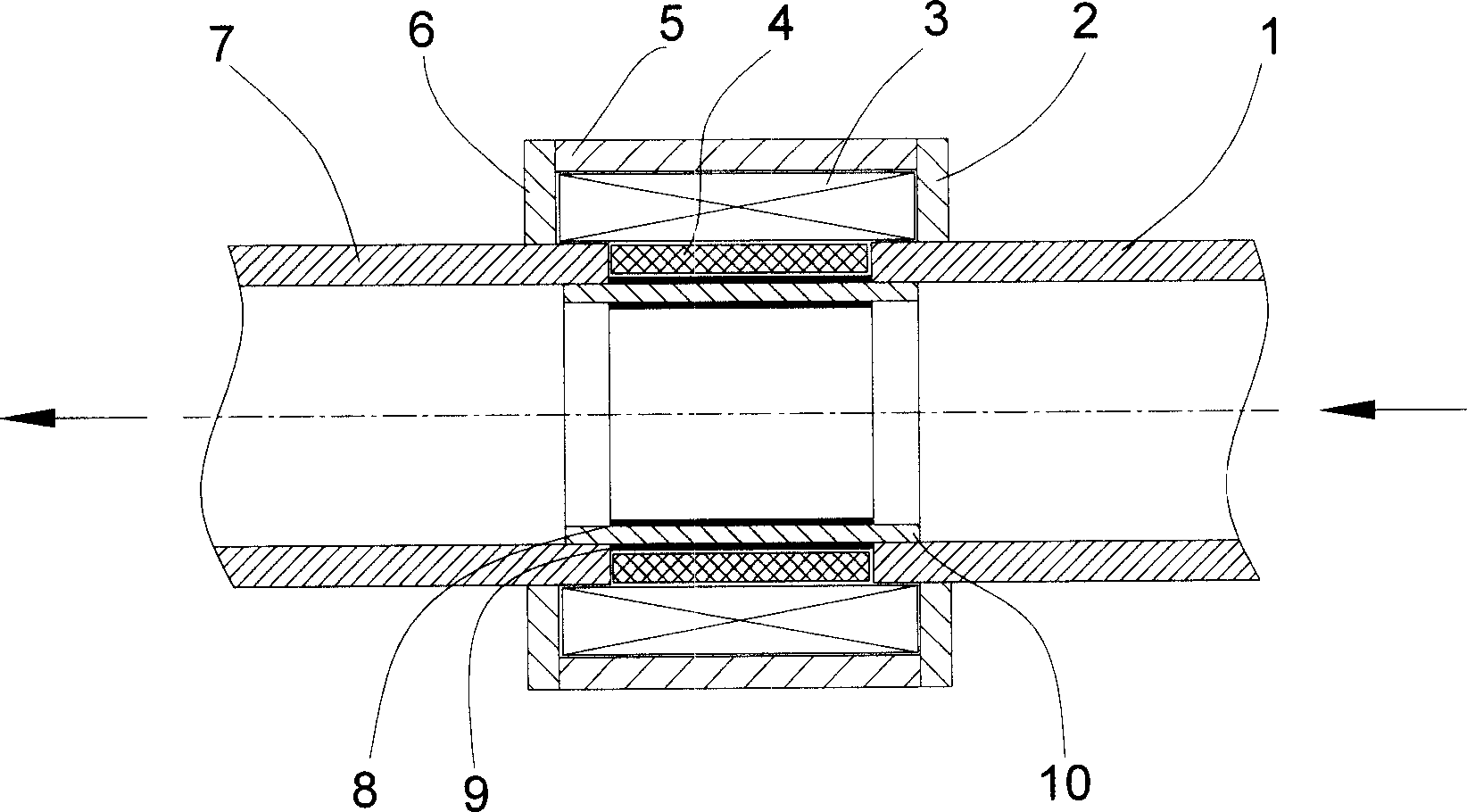

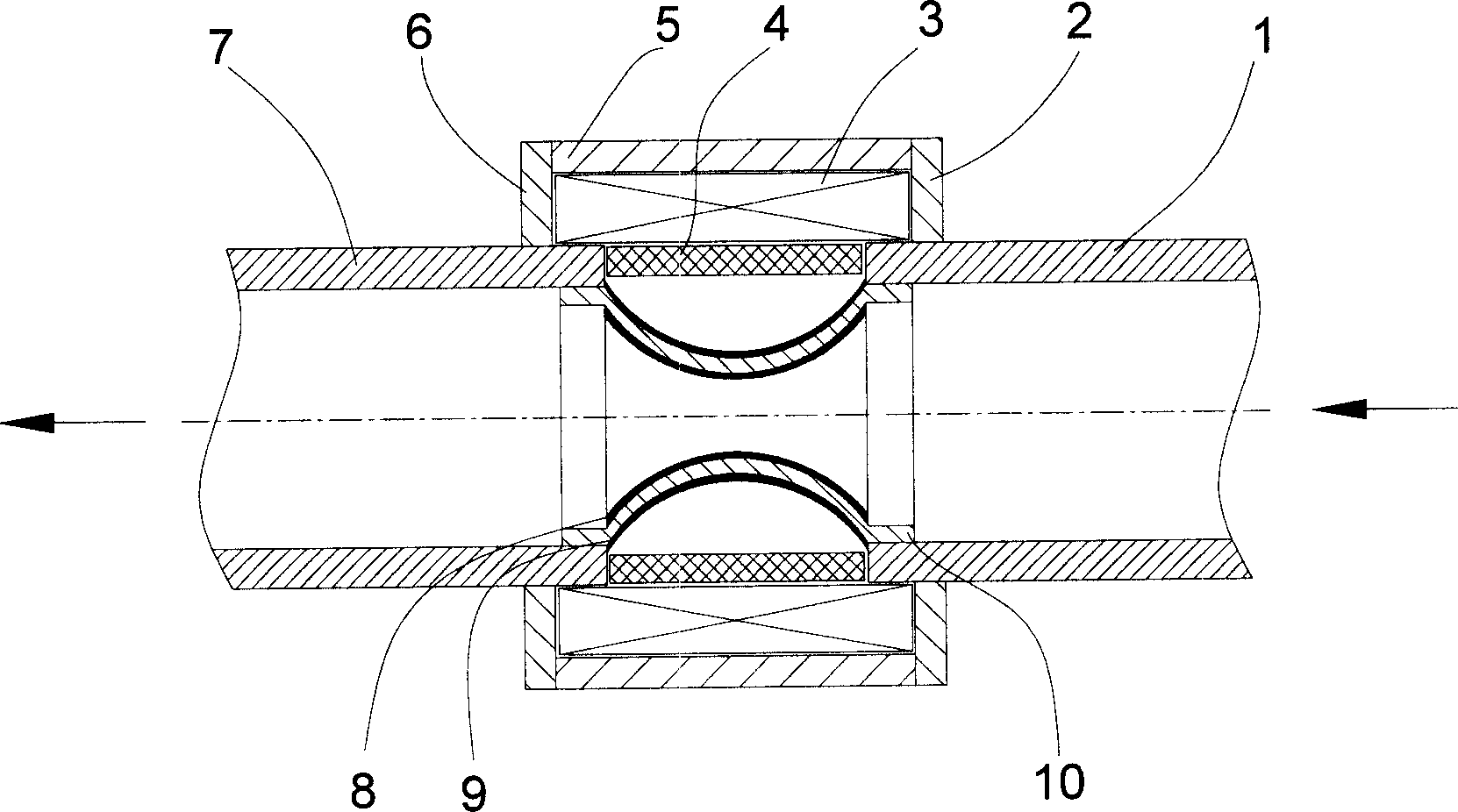

[0014] The liquid refrigerant enters the tube throttling device from the inlet pipe section 1. When refrigeration, air conditioning, and heat pump systems require a large refrigerant flow rate, the coil 3 of the tubular throttling device does not pass current, and the middle pipe section of the tubular throttling device is in the figure 1 In the state shown in , the flow area of the refrigerant is the largest at this time. When the operating conditions of the refrigeration, air conditioning, and heat pump systems change, and the flow rate of the refrigerant needs to be adjusted to a small value, a current is passed through the coil 3 to generate a magnetic field. The positive magnetostrictive material 8 on the inner surface of the intermediate pipe section is axially elongated under the action of the magnetic field, the negative magnetostrictive material 9 on the outer surface of the intermediate pipe section is axially shortened under the action of the magnetic field, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com