Method for measuring heterogeneous texture parameter distribution of particle fluid two-phase flow system

A structural parameter, non-uniform technology used in machine/structural component testing, measuring devices, fluid dynamics testing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

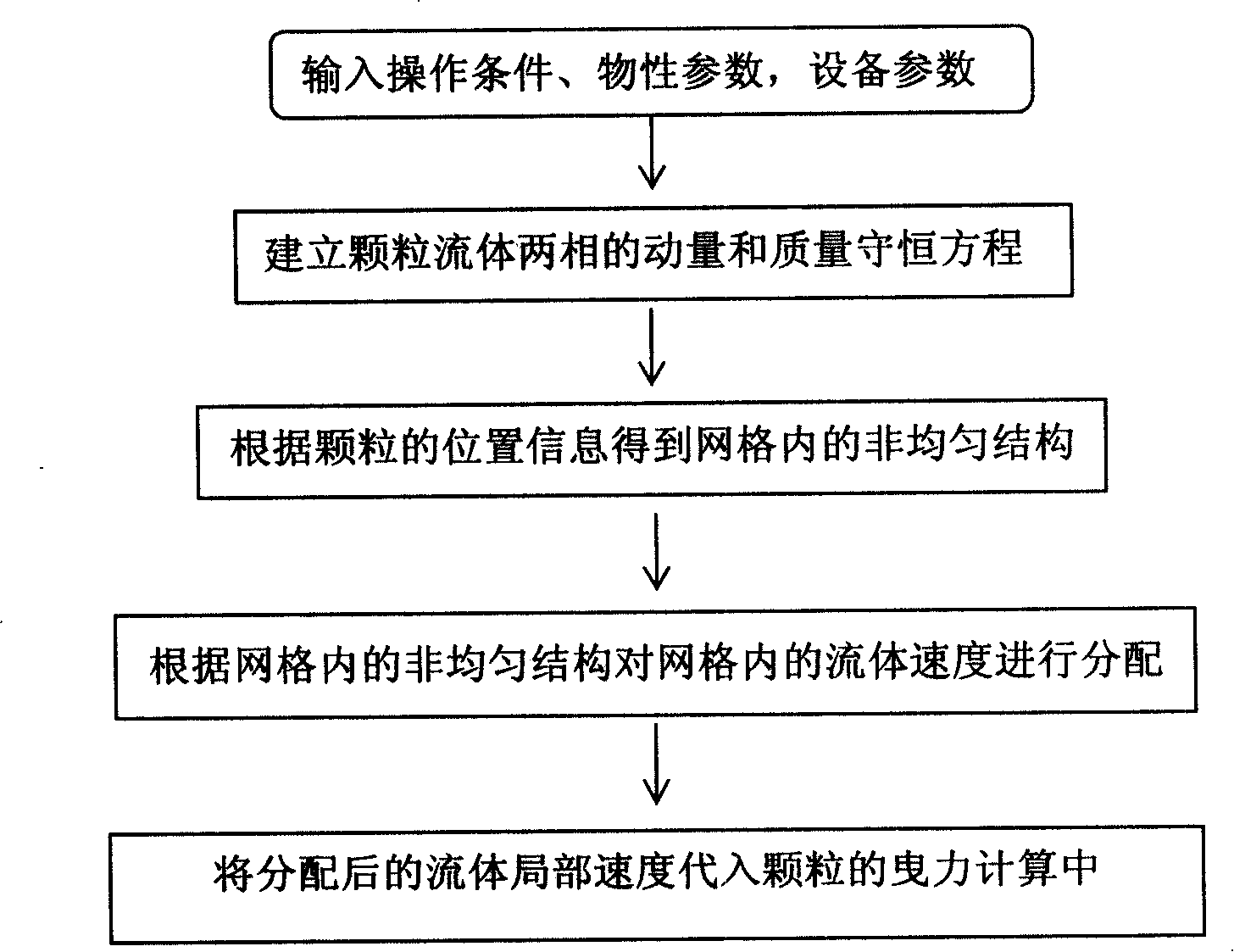

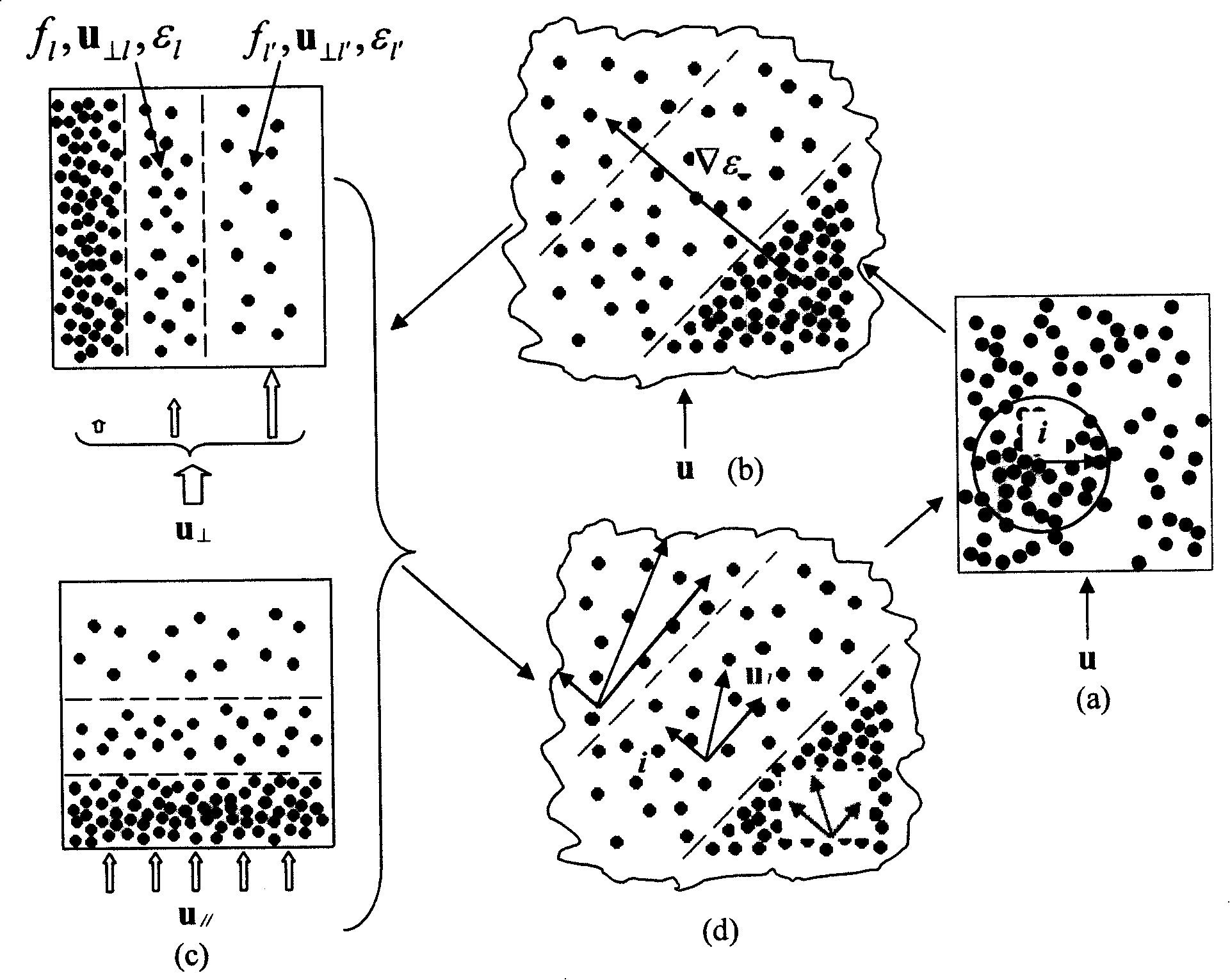

[0045] Such as figure 1 As shown in the granular fluid system with heterogeneous structure, the granular fluid two-phase flow reactor includes circulating fluidized bed or riser reactor, and may also be other granular fluid reactors with heterogeneous structure. against figure 1 The non-uniform structure of the particle fluid two-phase flow system shown, the method steps for measuring the parameter distribution of the structure are as follows figure 2 As shown, the specific steps are as follows:

[0046] Step 1. Determine the input conditions when the measurement method is implemented, specifically including: solid phase particle diameter d p , particle density ρ p , gas phase density ρ g , gas phase viscosity μ, equipment parameters: equipment height H and diameter W, etc., operating conditions: superficial fluid velocity u and particle i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com