Composite diaphragm and its making method

A manufacturing method and bonding technology, applied in the direction of diaphragm structure, sensors, electrical components, etc., can solve the problems of high production cost, complex coating process, thin nano-scale metal film or oxide film coating thickness, etc., and achieve simple manufacturing method , low production cost, high strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

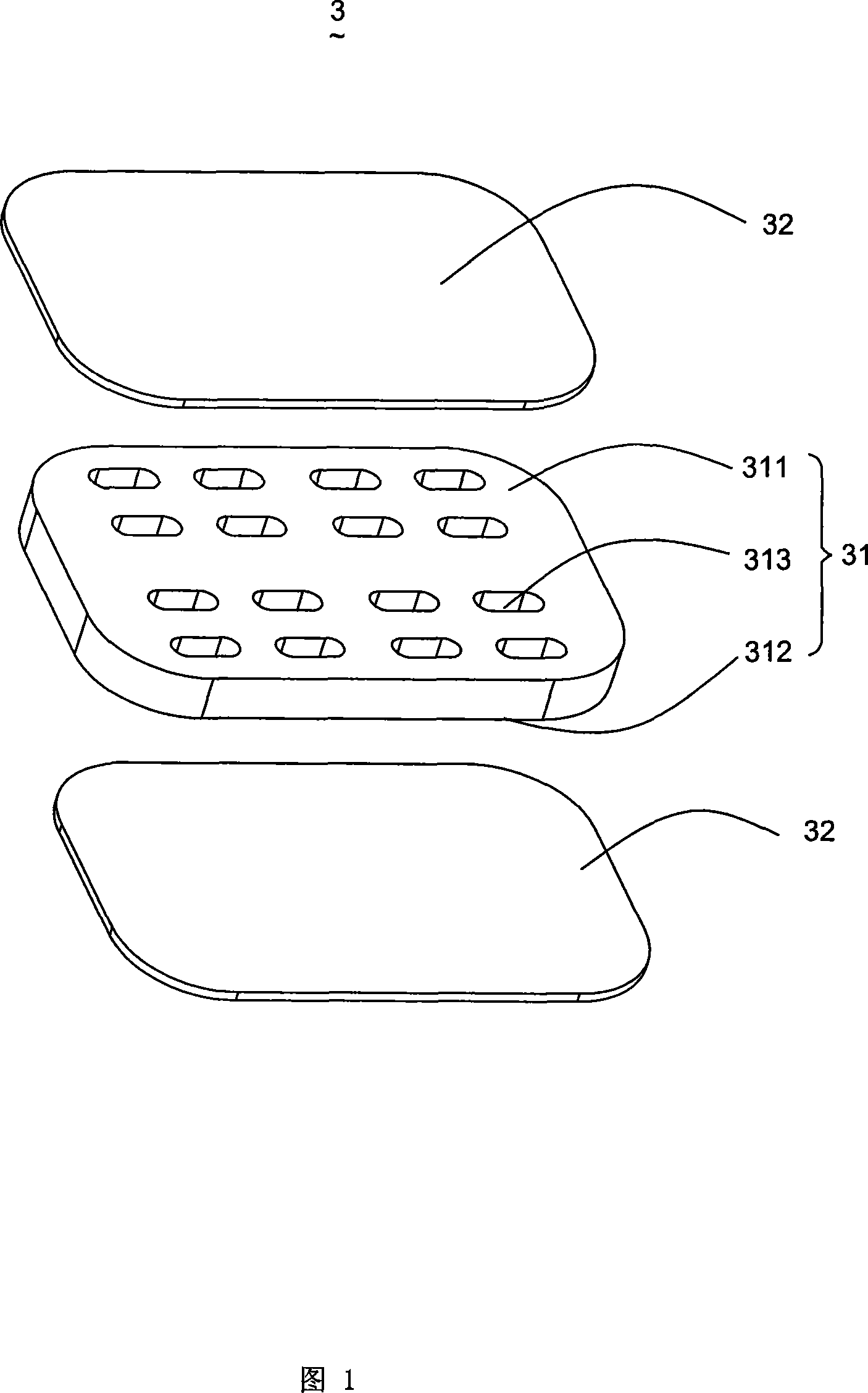

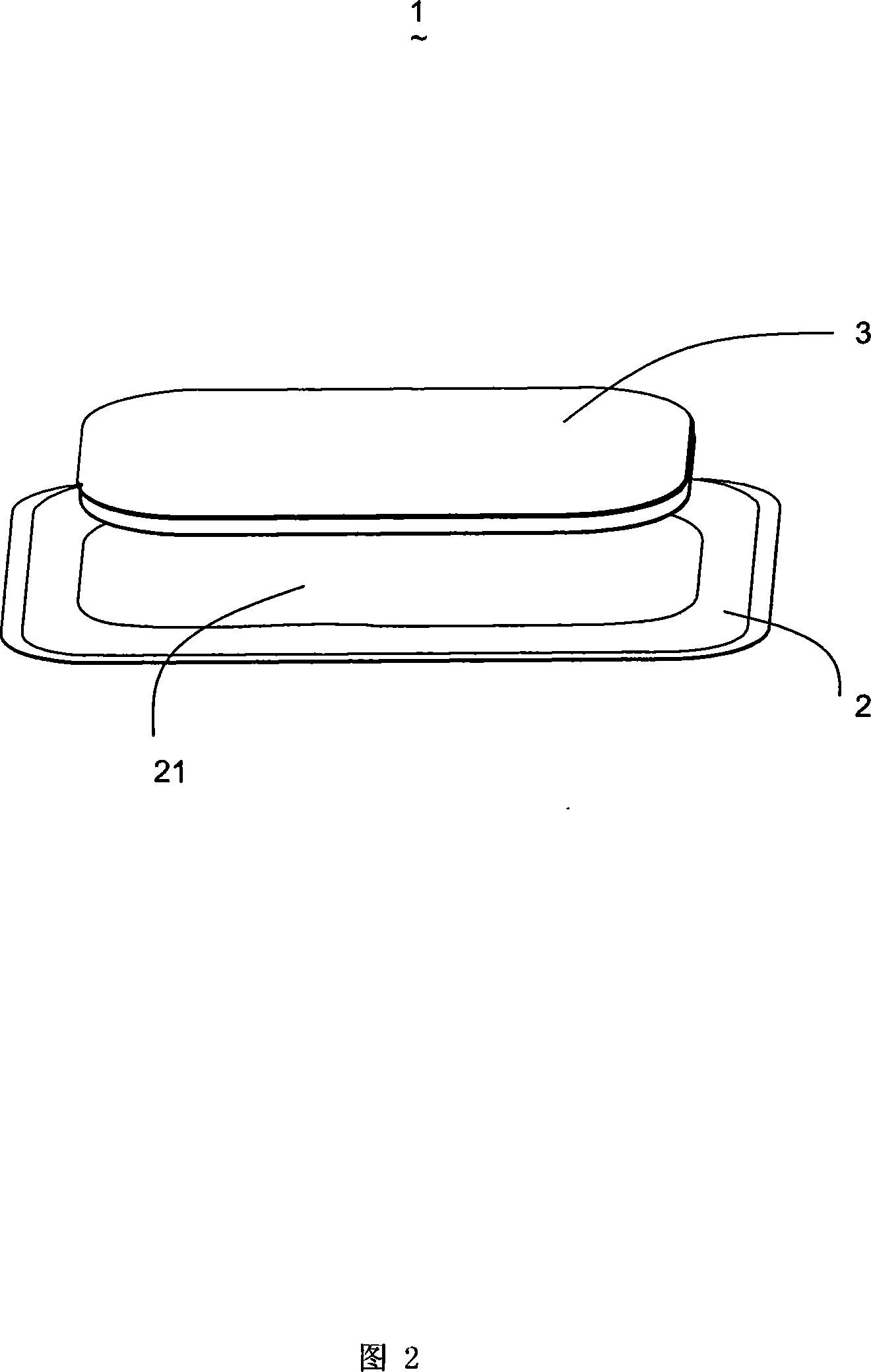

[0020] The metal foil 32 is preferably aluminum foil, and can be connected to the middle plate 31 by gluing. The first embodiment of the present invention: the metal foil 32 is glued to the upper surface 311 and the lower surface 312 of the middle plate 31 at the same time; Embodiment: the metal foil 32 is only glued to the upper surface 311 (not shown) of the middle plate 31; in addition, the third embodiment of the present invention is: the metal foil 32 is only glued to the lower surface 312 (not shown) of the middle plate 31 ).

[0021] By gluing the metal foil 32 on the middle plate 31 , the plate dome 3 has high strength, thereby expanding the high-frequency characteristics and sound characteristics of the product using the composite diaphragm 1 .

[0022] A method for manufacturing a composite diaphragm 1, comprising the following steps:

[0023] Provide the middle plate 31; apply glue on the surface of the middle plate 31; provide the metal foil 32; connect the metal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com