Dental prosthetic manufacturing method

A prosthesis and dental technology, applied in the field of dental prosthesis and its production, can solve problems such as difficulty in obtaining the maximum retention force, and achieve the effects of reducing medical accidents, preventing degradation and reducing time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0070] Below, refer to Figures 18 to 37 , the integral type holding portion 1 will be described in detail.

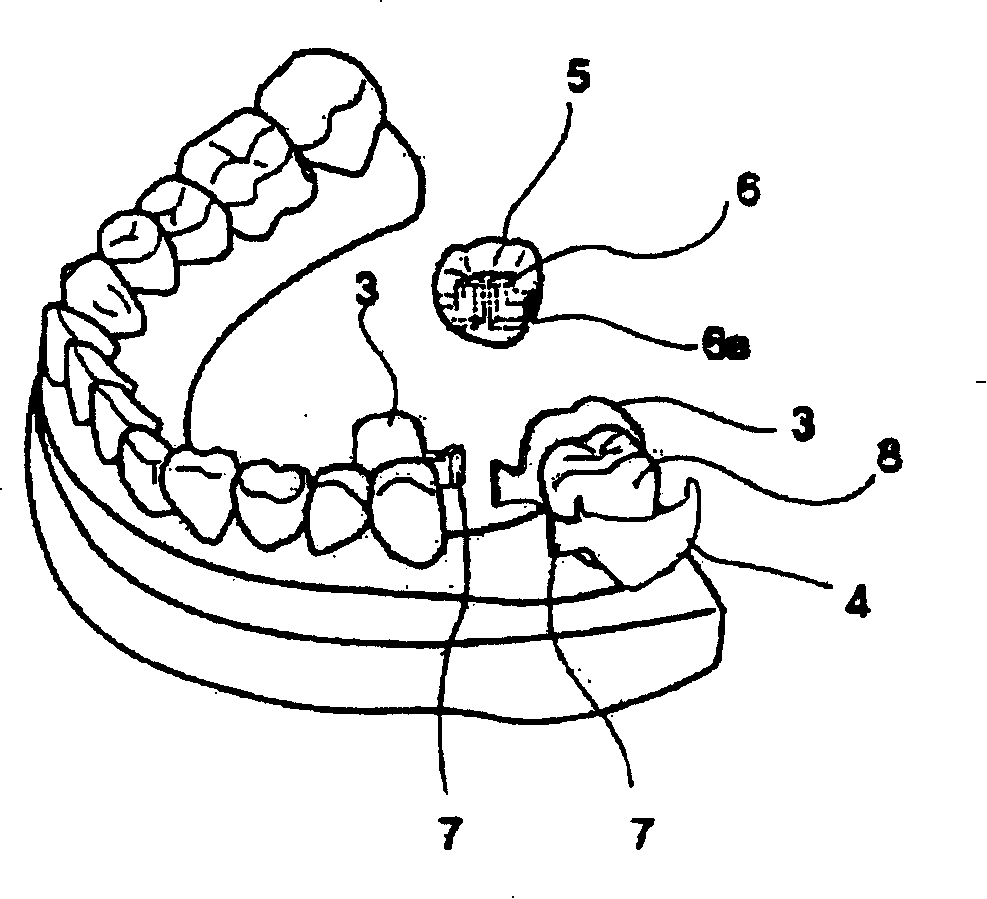

[0071] The dental restoration according to the present invention comprises a holding part 1 , a protrusion 9 formed on the holding part 1 , a male member 7 attached to the holding part 1 and a female member 6 formed on the artificial tooth 5 .

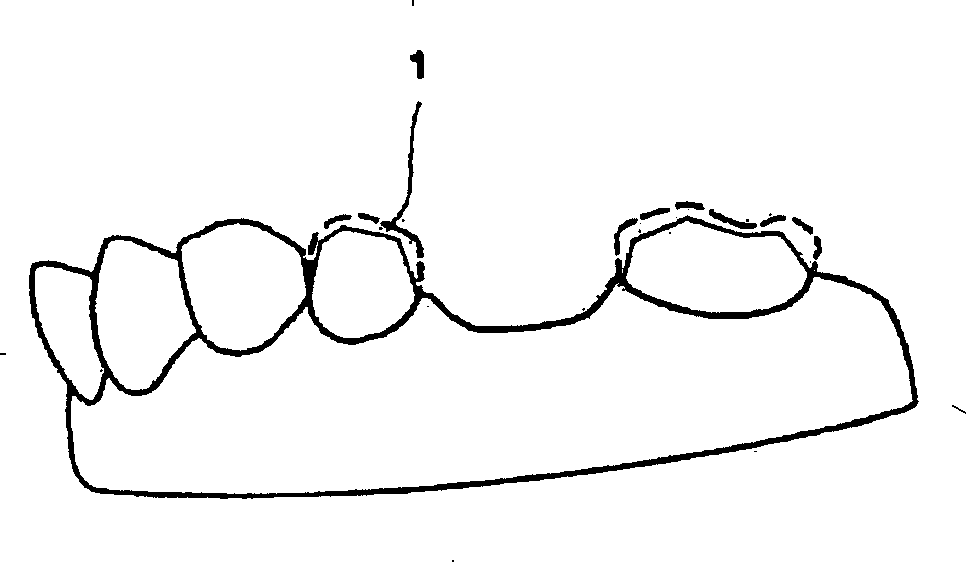

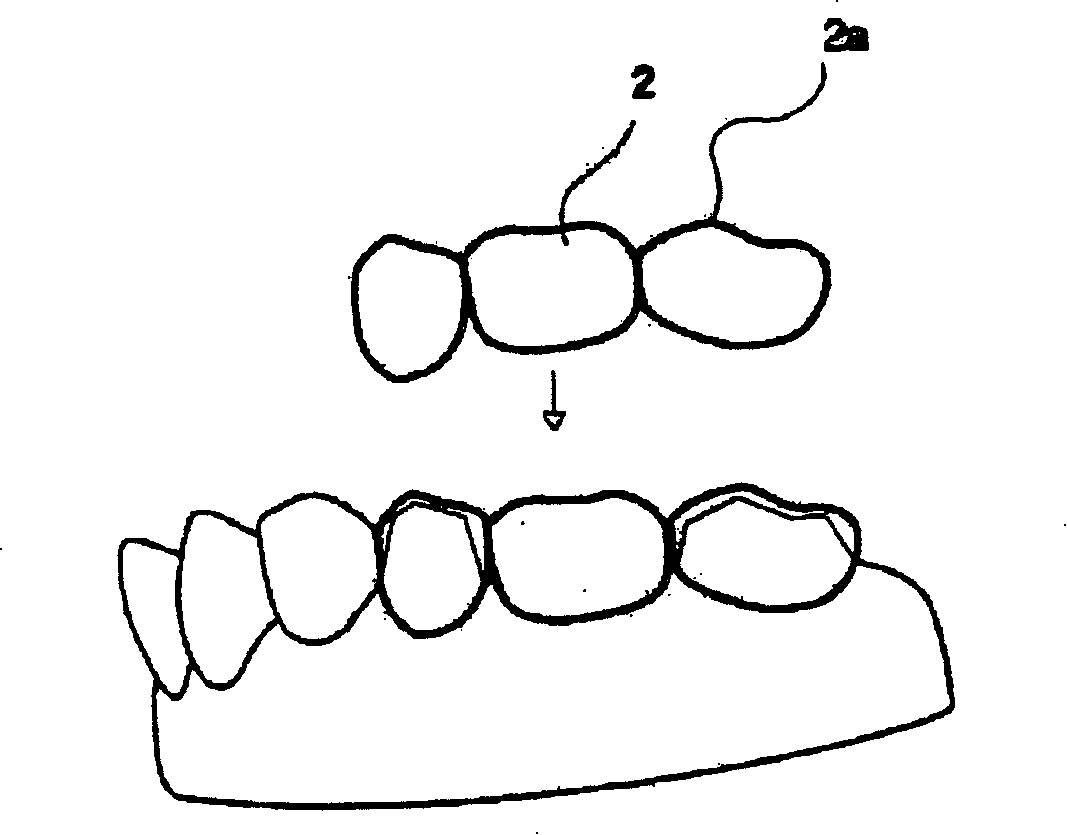

[0072] The retaining part 1 may have one of different forms in view of retaining power and aesthetics, for example, a form in which the retaining part 1 is limited only to the polished proximal surface ( Figure 22 ), a form in which the retaining portion 1 extends from the ground proximal surface to the lingual side (Figure 20), a form in which the retaining portion 1 extends from the ground proximal surface to the buccal side (Figure 21), or a form in which the The retaining portion 1 extends to the lingual and buccal sides (Fig. 19). The form and size of the grinding of the retaining portion 1 can vary according to the siz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com