Heavy hammer pre-pressurization device

A pre-pressurization and heavy hammer technology, which is applied in the direction of presses, forming indenters, and material forming presses, etc., can solve problems such as pollution, increased vibration inertia, and large vibration power consumption, so as to avoid environmental pollution and reduce Effect of vibrating mass and reducing weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

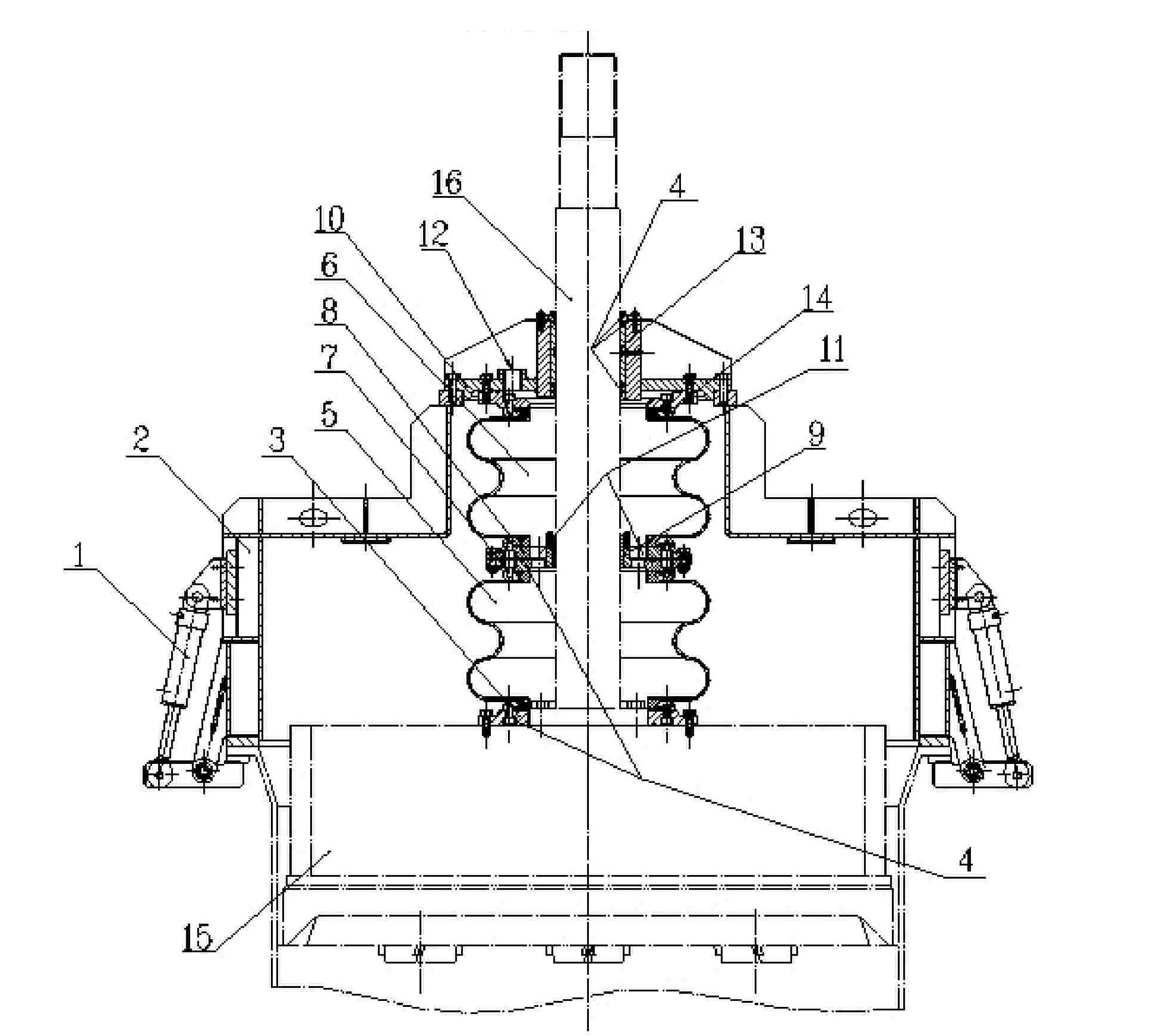

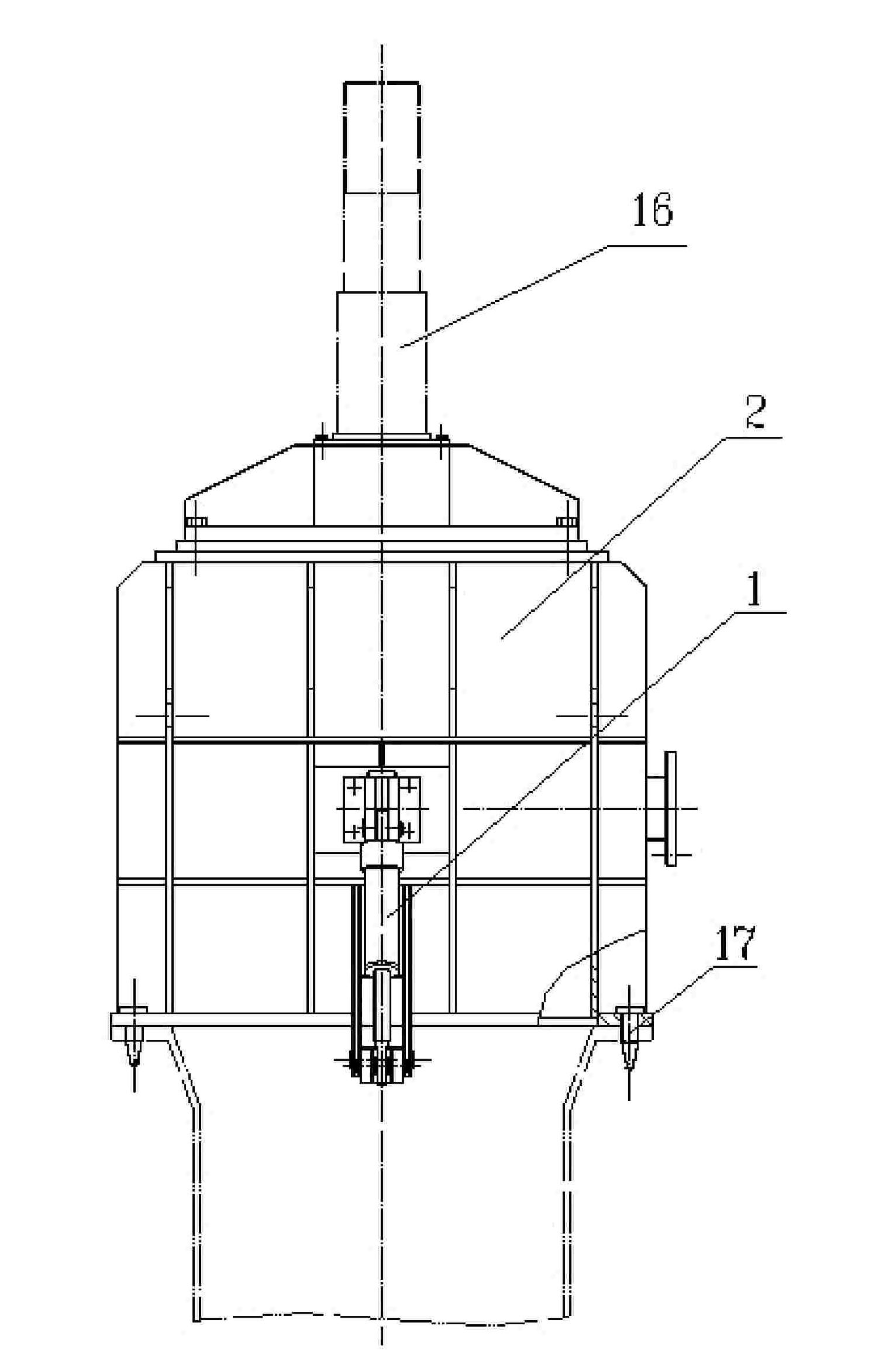

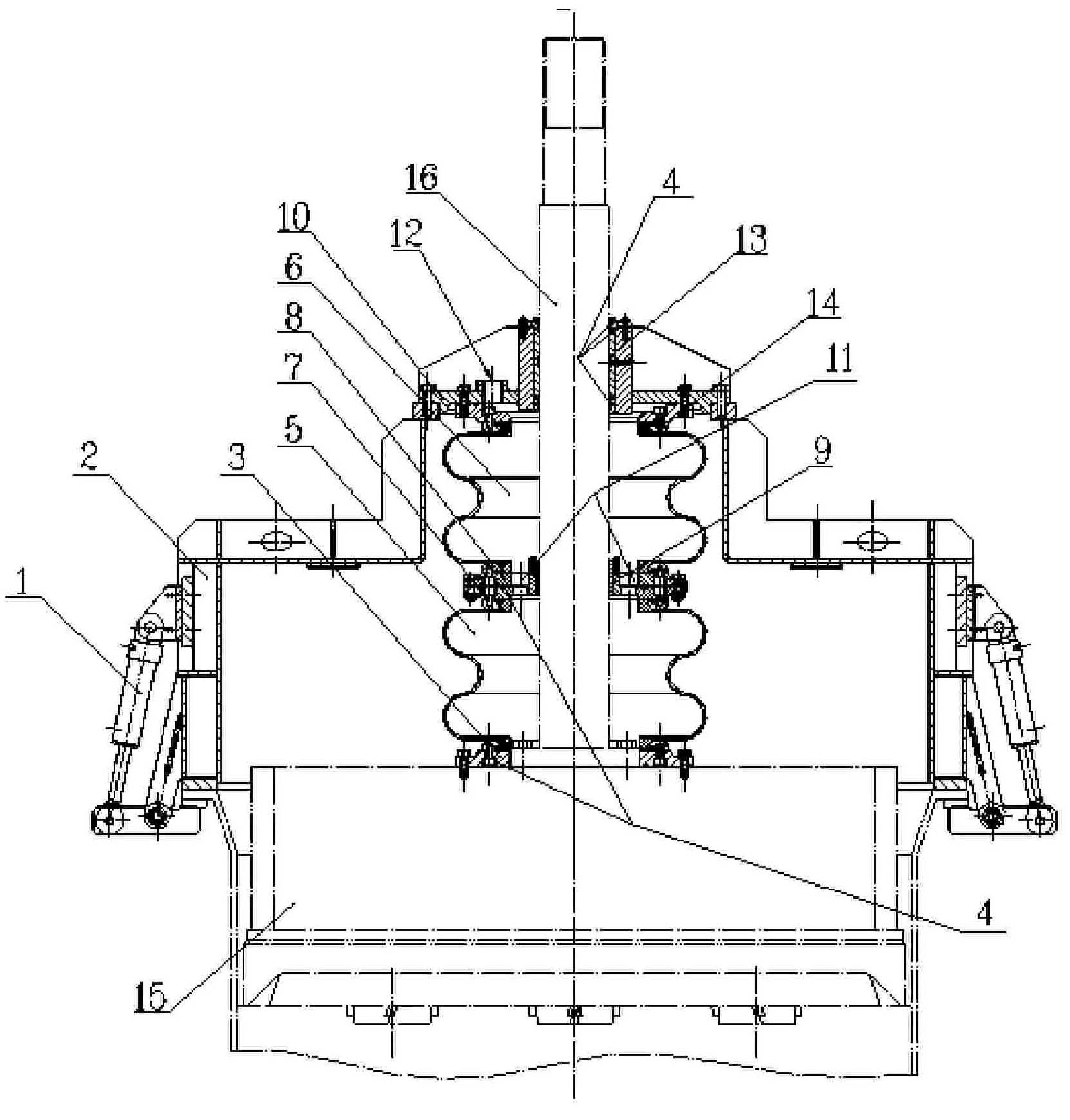

[0011] Embodiment: the structure of weight preloading device is as figure 1 As shown, the upper part of the weight 15 is connected to the lower end of the weight guide shaft 16, and the connection plate 3, the rubber air bag 5, the connection plate 7, the connection plate 8, the rubber air bag 6 and the connection plate 14 are connected in series through the weight guide shaft 16, and the weight The upper part of the hammer 15 is connected to the connecting plate 3, the lower part of the rubber air bag 5 is connected to the connecting plate 3, the upper part of the rubber air bag 6 is connected to the connecting plate 14, and the connecting seat 10 is connected to the connecting plate 14 through the weight guide shaft 16 and fixed on the casing ( 2) The upper part, the connecting seat 10 is provided with an air inlet 12, the air inlet 12 passes through the connecting plate 14 and communicates with the rubber air bag 6, the sealing seat 13 passes through the weight guide shaft 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com