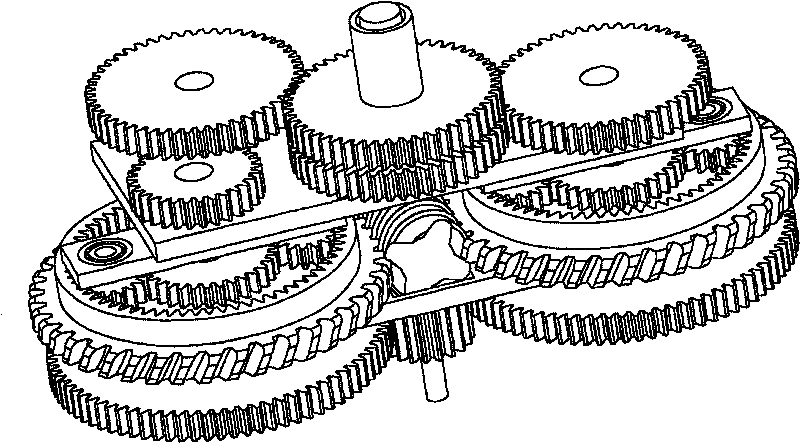

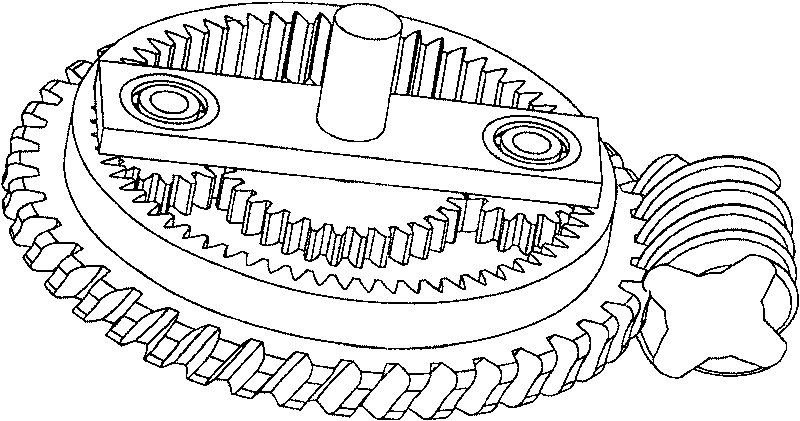

Helicopter co-axis double rotator rotate speed differential device

A technology of coaxial dual rotors and differential rotation speed, applied in the field of helicopters, can solve the problems of differential rotation speed and complex structure of two rotors, and achieve the effect of reducing interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

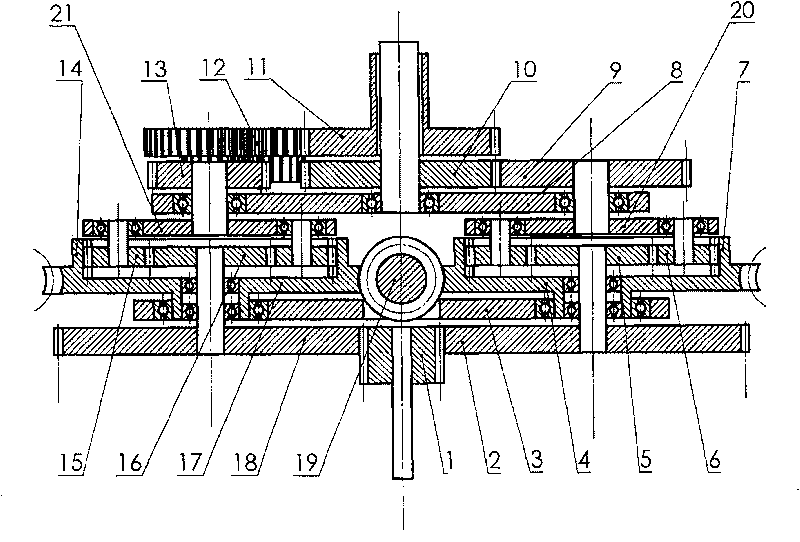

[0037] exist figure 2 In the schematic diagram of the longitudinal section structure, the parts below the upper support frame (8) are left-right symmetrical, and the power is divided into two strands, which drive the inner shaft and the outer shaft of the rotor respectively.

[0038] The power transmission route on the right is as follows: the power input gear (1) meshes with the first-stage reduction gear (2) on the right, and transmits the power to the first-stage reduction gear (2) on the right, which is the first-stage transmission; The stage reduction gear (2) is coaxially and rigidly connected with the right sun gear (5), and the right sun gear (5) meshes with the right planetary gear (6), and the right planetary gear (6) also engages with the right internal gear (7) meshing, when the speed differential is not performed, the right internal gear (7) is stationary, and the power is transmitted from the right primary reduction gear (2) to the right sun gear (5), and then d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com