Fabric pincher elasticity tester

A tester and fabric technology, which is applied in the field of fabric crease elasticity tester, can solve the problems of low measurement accuracy, large deviation of fabric crease recovery angle, and large manual workload.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described now in conjunction with accompanying drawing:

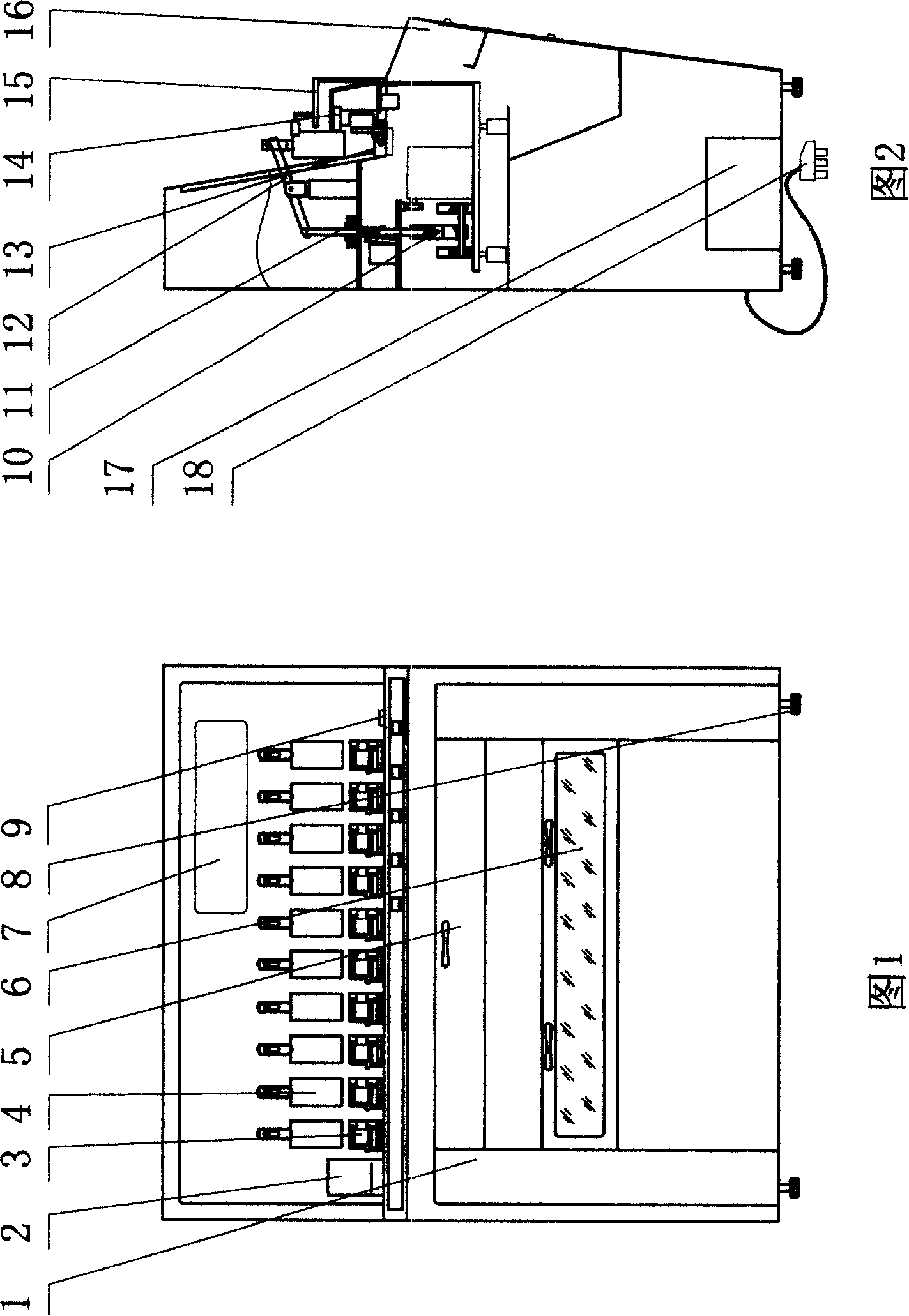

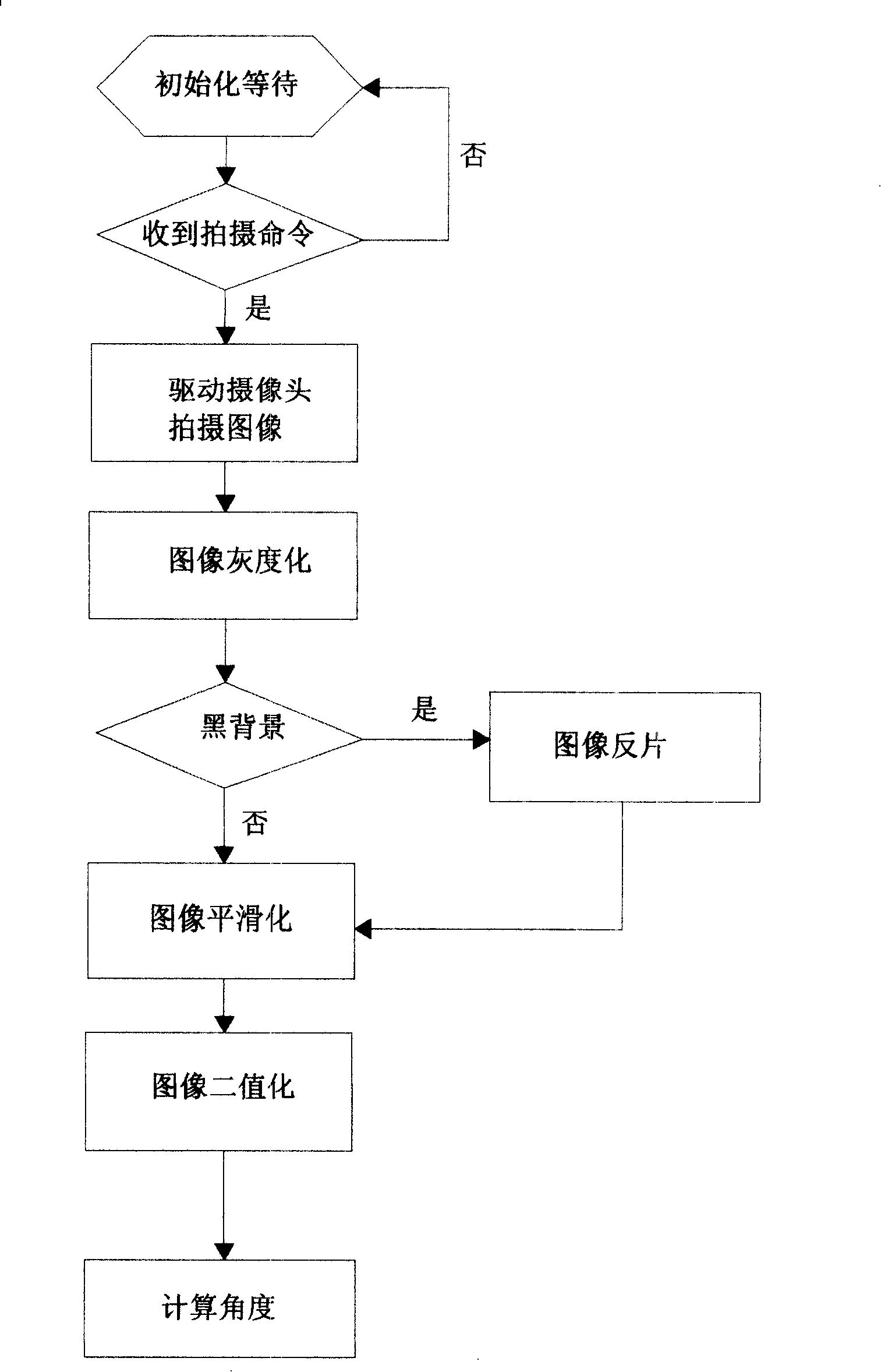

[0011] From Figure 1 to image 3 It can be seen that a fully automatic digital fabric wrinkle elasticity tester of the present invention includes a frame 1, and ten fabric clamping devices arranged horizontally and ten weight devices correspondingly provided on the frame 1 4. The clamping device is composed of an electromagnet 13 and a turning plate 3, wherein the electromagnet 13 is fixed on the platform of the frame 1, and the turning plate 3 is hinged to the electromagnet 13. Usually, there is an edge along the front of the holding device. The trolley 2 sliding on the horizontal guide rail is fixed with a camera 14 on the upper end of the trolley 2, and the camera 14 is slidably arranged above the turnover plate 3, and is used for photographing 1-10 fabrics on the fabric clamping device For the image of the sample after bending and recovery, there is also a microcomputer i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com