System, redundant circuit and method for driving light emitting diode

A technology of light-emitting diodes and driving methods, which is applied to electroluminescent light sources, control/regulation systems, light sources, etc., and can solve problems such as sacrifice of luminous stability, inability to universally apply light-emitting diodes, and increased mass production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The above and other technical features and advantages of the present invention will be described in more detail below in conjunction with the accompanying drawings.

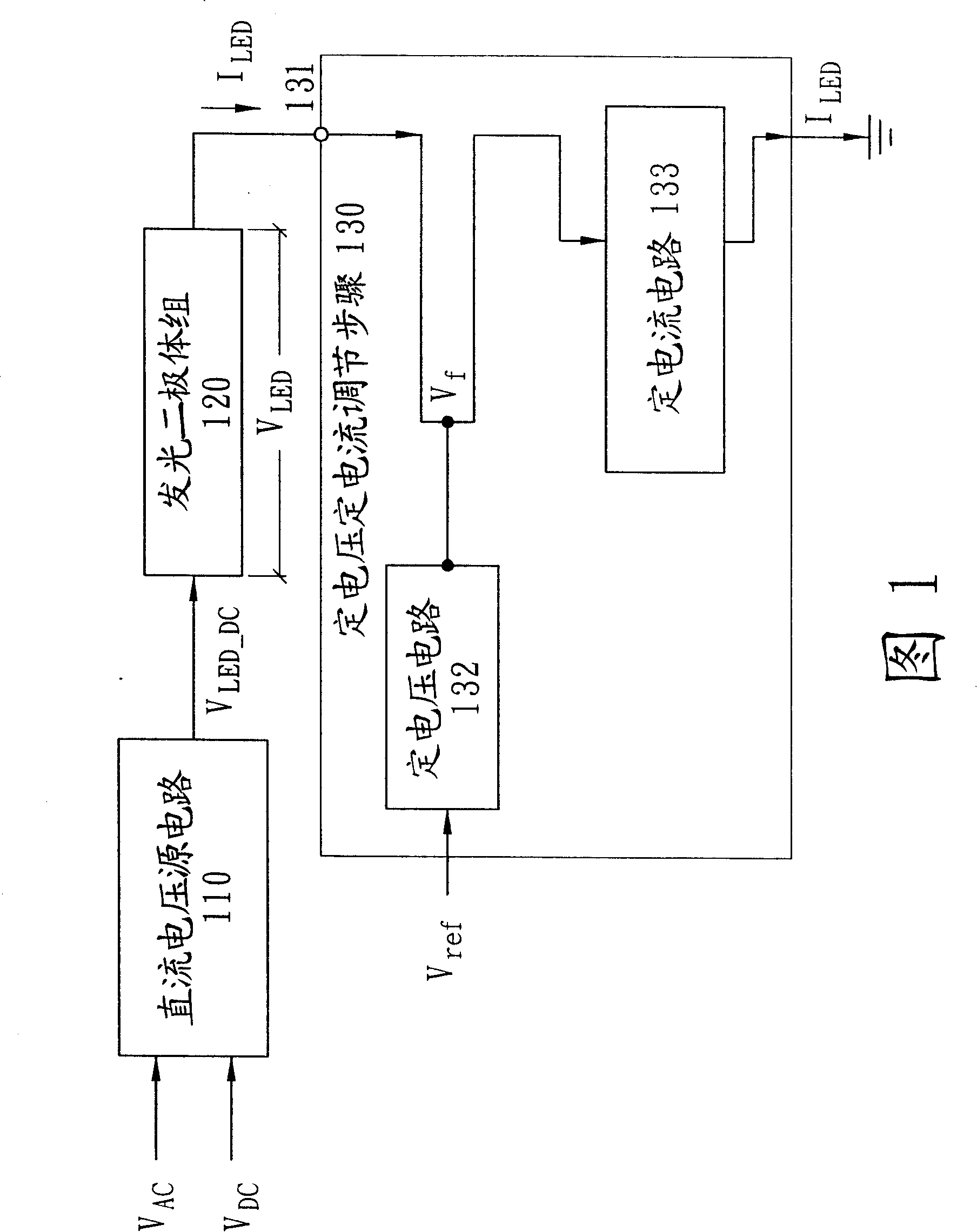

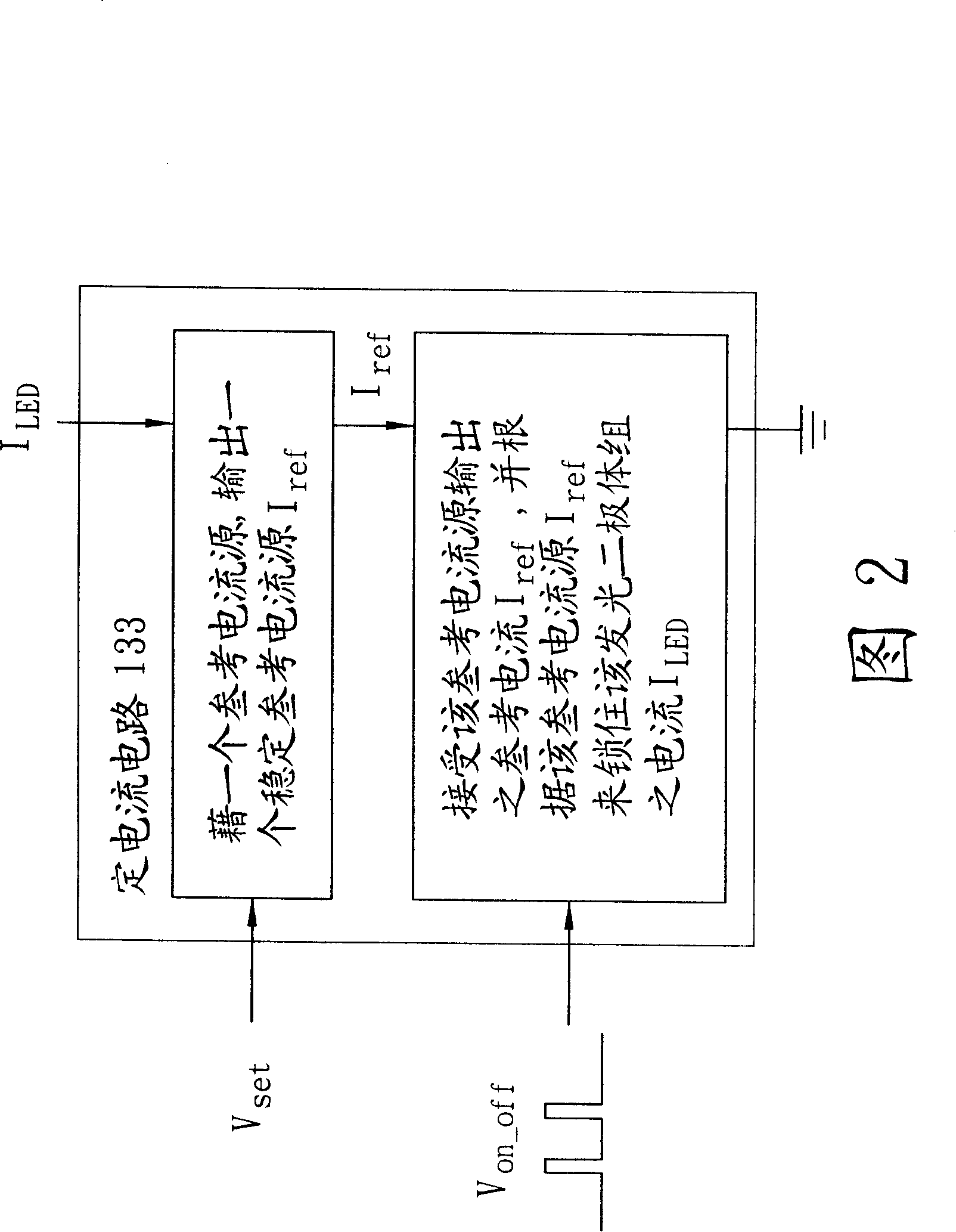

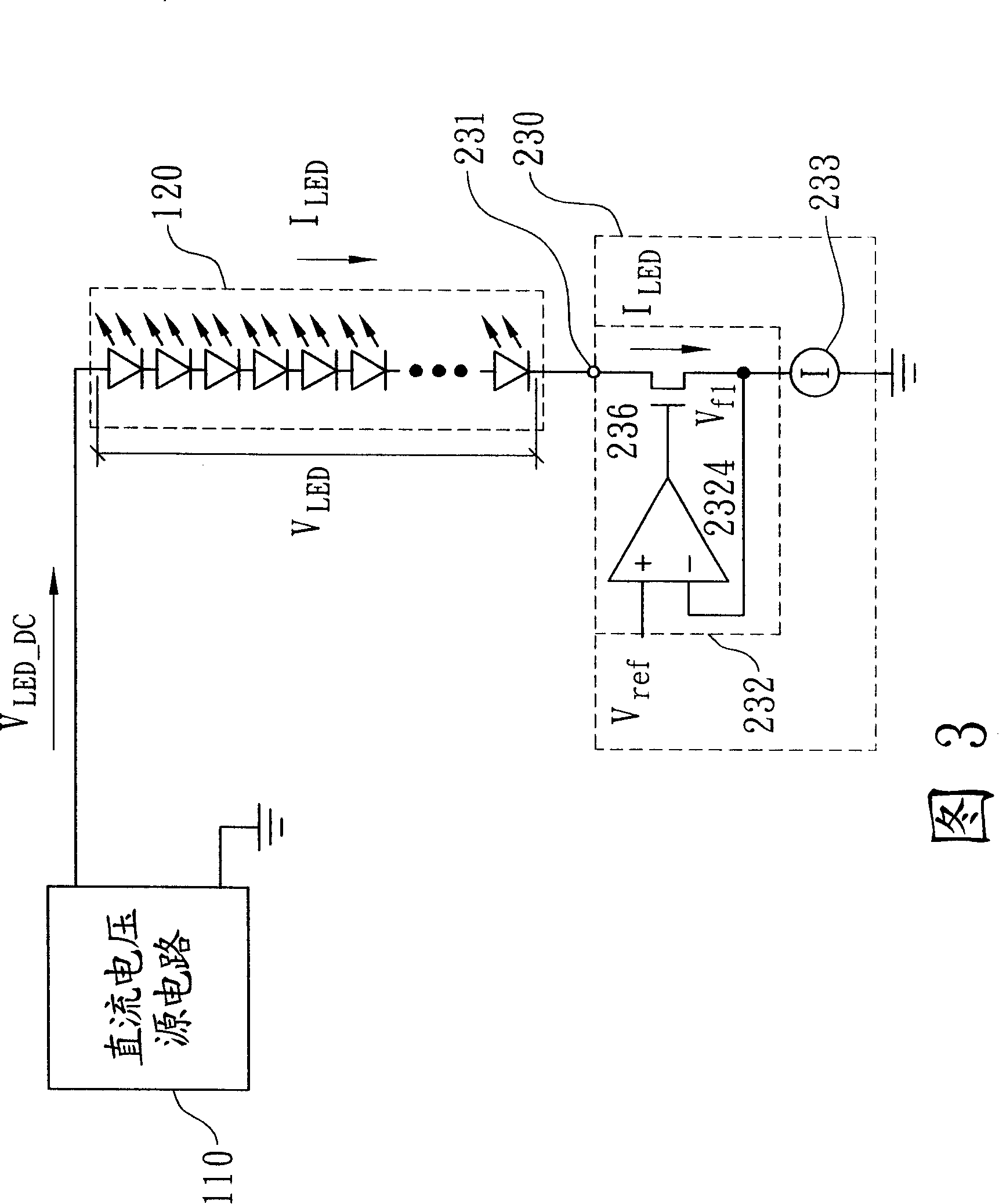

[0044] Fig. 1 is the diagram of the first embodiment of the driving method of the light-emitting diode of the present invention, which is mainly divided into three steps, wherein the first step is that a DC voltage source circuit 110 outputs a DC power supply VLED_DC; the second step is to convert the DC voltage VLED_DC is pressurized to a light emitting diode group 120 to generate a current ILED flowing through the light emitting diode group to make the light emitting diode group emit light. The light emitting diode group is a single light emitting diode, or a plurality of light emitting diodes are connected in series to form a light emitting diode string and the third step is a constant voltage and constant current adjustment step 130, which stabilizes the current ILED flowing through the light-emitting d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com