Car rear axle semi-axis structure

A technology of rear axle and axle structure of automobiles, applied in axles, wheels, vehicle parts, etc., can solve the problems affecting rear brake adjustment structure, brake shoe arrangement, inconvenient installation of brake floor, and influence on vehicle layout, etc., to achieve cost reduction Low, improve the service life, meet the effect of layout requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

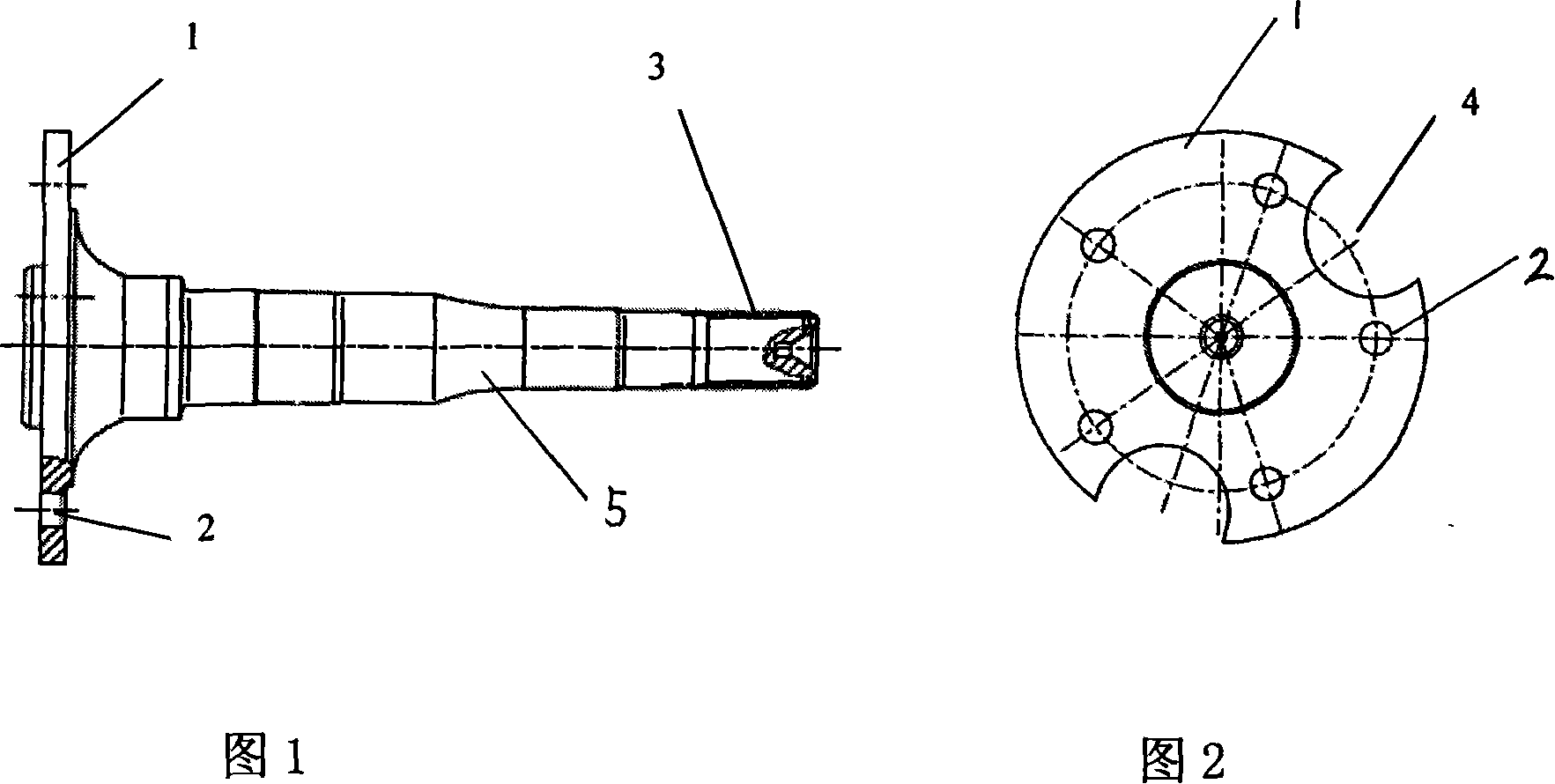

[0010] Referring to Fig. 1 and Fig. 2, the semi-axle of the rear axle of the automobile comprises a semi-shaft flange 1 at the end of the semi-shaft 5, and five wheel bolt holes 2 are evenly distributed on the semi-shaft flange 1. There are also two semicircular relief gaps 4 for the installation of the brake base plate on the edge plate 1 .

[0011] The half-shaft structure of the rear axle is a semi-floating structure, and is installed in the axle housing of the rear drive axle through two bearings. The driving force is transmitted to the rear axle shaft through the transmission, drive shaft, final drive, side gear, spline 3 on the side shaft, and then to the wheels through 5 bolts installed in the half shaft bolt hole 2. When installing, firstly press 5 half shaft bolts respectively on the five wheel bolt holes 2 of the half shaft flange plate 1; Half shaft bearing and bearing retaining ring, assemble the half shaft bearing and retaining ring through a press; insert the as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com