Power system for composite cycle vehicle

A power system, compound cycle technology, applied in hybrid vehicles, power plants, pneumatic power plants, etc., can solve the problems of complex driving and control systems, poor adaptability to complex working conditions, secondary pollution of batteries, etc., and achieve low emissions. , easy to implement, and the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

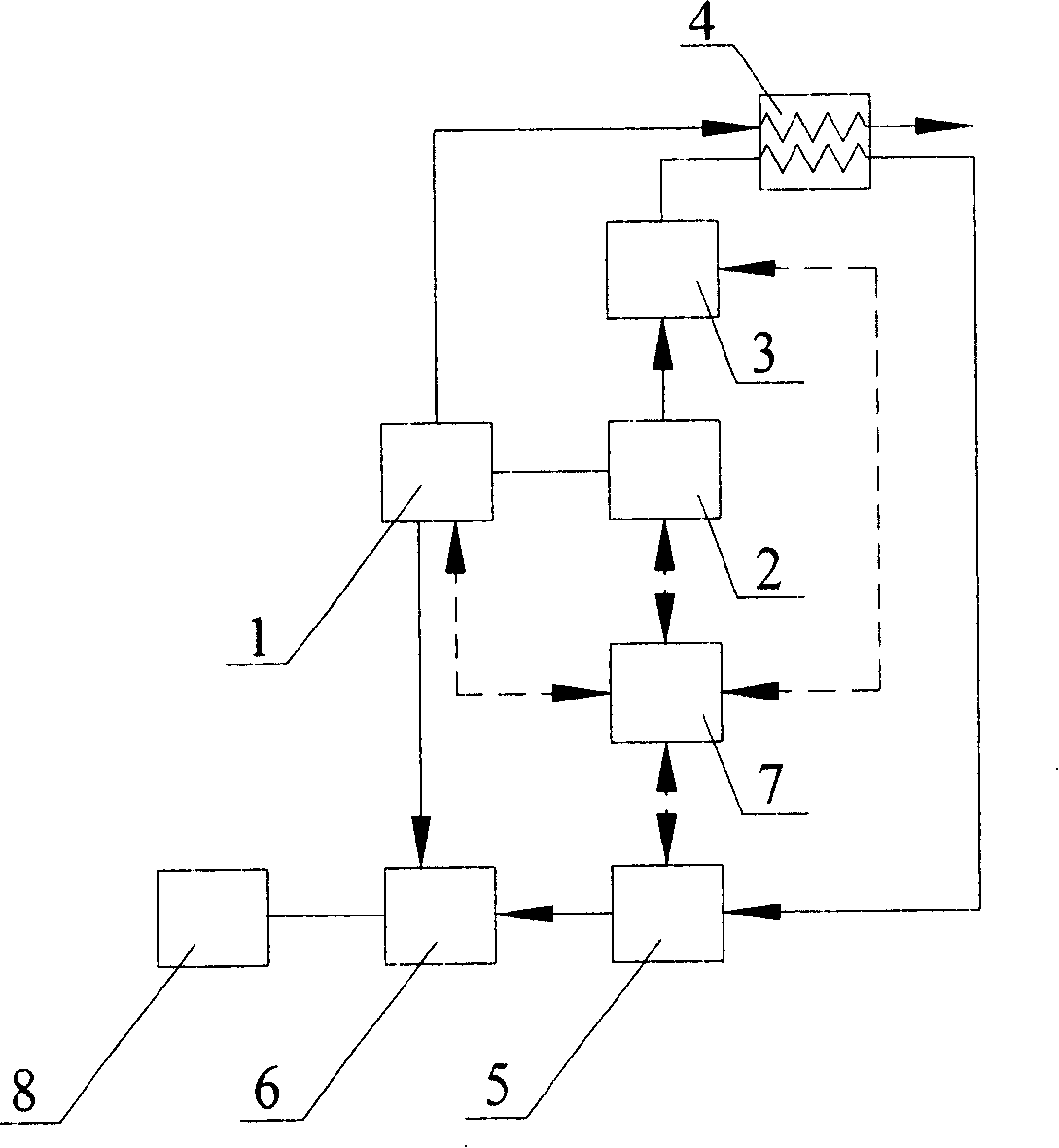

[0007] now attached figure 1 for further clarification. The present invention comprises an engine 1 , an air compressor 2 , an air storage tank 3 , an exhaust gas heat exchanger 4 , a turbine 5 , a clutch 6 , a central control mechanism 7 , and a chassis 8 . Between the engine 1 and the air compressor 2, between the engine 1 and the chassis 8, between the turbine 5 and the chassis 8, between the air compressor 2 and the chassis 8, several clutches 6 are used to connect respectively, and the air compressor 2 and The air storage tank 3 is connected, the engine 1 and the air storage tank 3 are both connected with the exhaust gas heat exchanger 4 , the exhaust gas heat exchanger 4 is connected with the turbine 5 , and the air compressor 2 is connected with the turbine 5 .

[0008] The entire power system can be divided into a top cycle power system and a bottom cycle power system: the top cycle power system is an engine 1, generally a high-performance internal combustion engine; ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap