Multifunctional telescopic conveyer

A telescopic machine and conveyor technology, which is applied in the directions of conveyors, conveyor objects, transportation and packaging, can solve the problems of low work efficiency, large space occupation, poor flexibility and adaptability, and achieves flexible and convenient use, compactness, Achieving the effect of miniaturization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

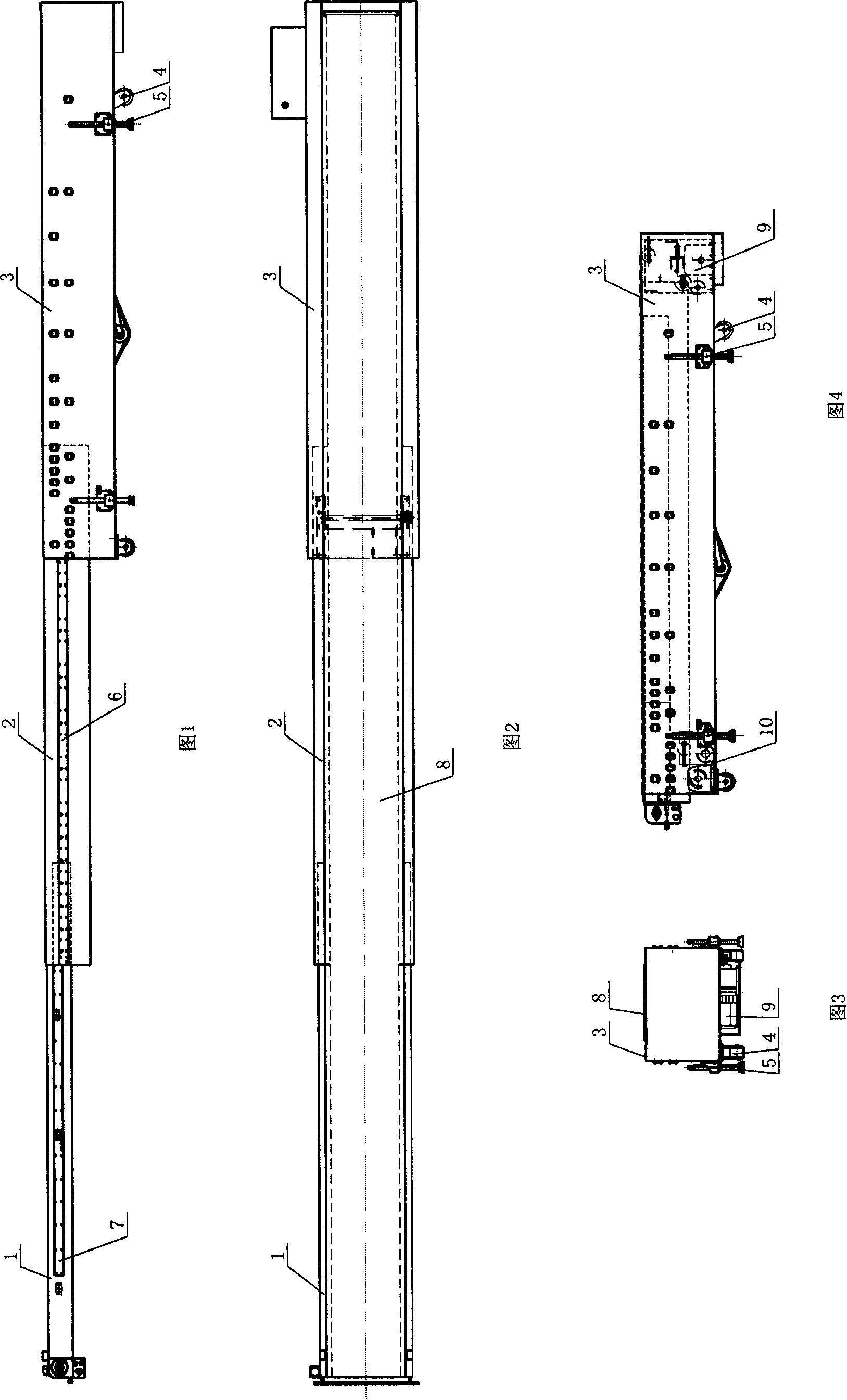

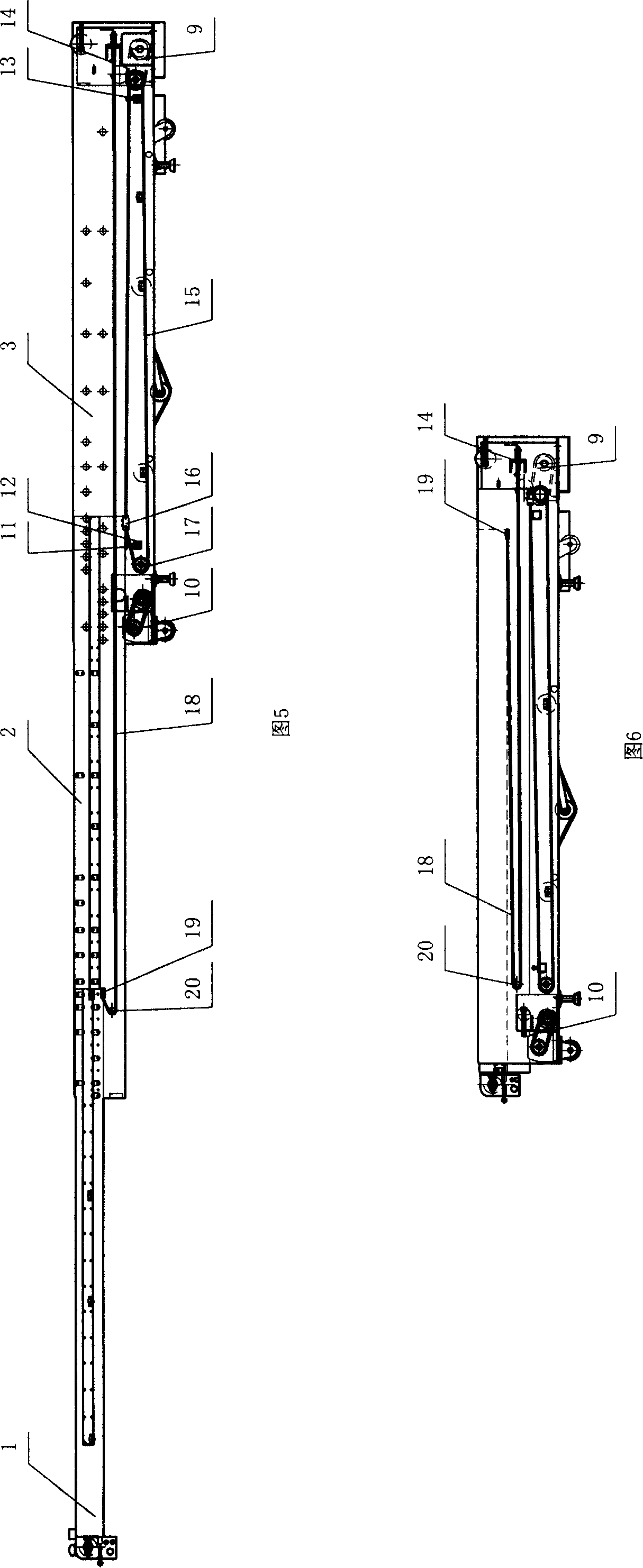

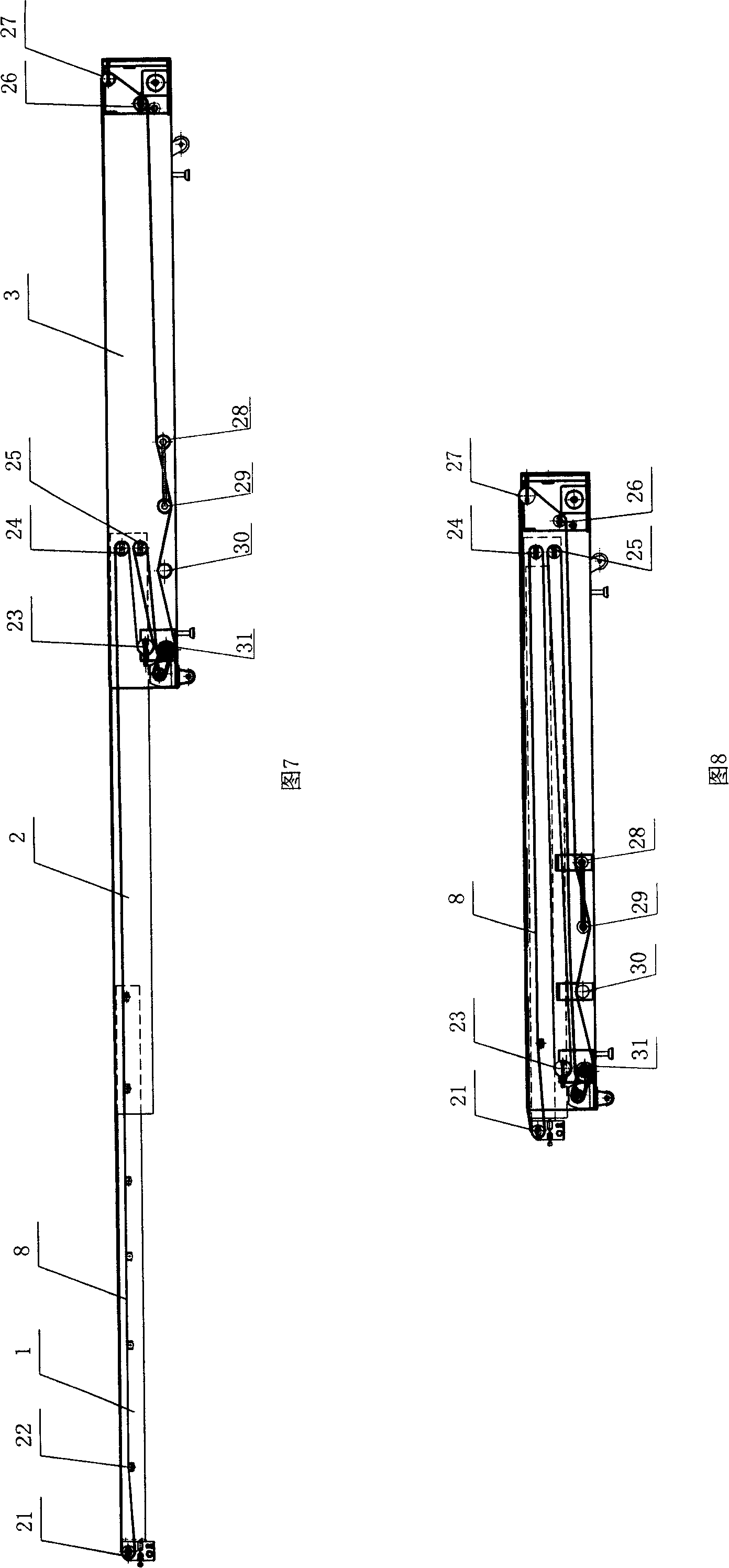

[0050] Embodiments of the present invention are described in further detail below in conjunction with the accompanying drawings:

[0051]The multifunctional telescopic conveyor is composed of a main frame 3, a front telescopic frame 1, and a rear telescopic frame 2. The rear telescopic frame is installed in the main frame, and the front telescopic frame is installed in the rear telescopic frame. . A telescopic transmission mechanism 9 is installed on the lower right side of the main frame, and the telescopic transmission mechanism drives and installs chains 15 on both sides of the main frame through a telescopic drive motor 48 so as to realize the extension and retraction of the rear telescopic frame and the front telescopic frame A chain plate transmission mechanism 10 is installed on the left side lower part of the main engine casing, and the chain plate transmission mechanism adopts the chain plate drum 31 to drive the chain plate 8 wrapped around the closed operation of ea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com