Sensitive light shield

A sensitive and photomask technology, applied in the field of sensitive photomasks, which can solve problems such as process risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

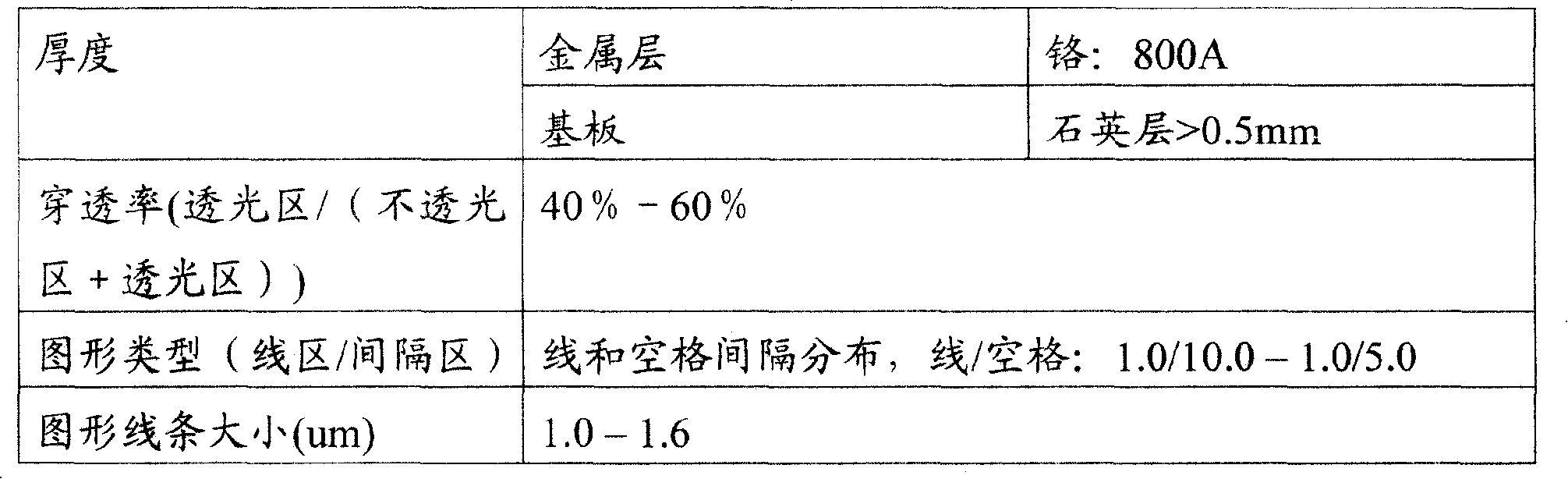

[0013] The present invention provides a sensitive mask, which has some specific technical parameters, as shown in Table 1 below:

[0014] Table 1

[0015]

[0016] A photomask having all the features in Table 1 is the sensitive photomask of the present invention.

[0017] see figure 1 , the white highlights are the crystals. Experiments have proved that under the same conditions, the sensitive mask is more likely to grow crystals during the exposure process than the common mask.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com