A high-strength and tough nitrided layer on the surface of an iron-based alloy and its preparation method

A technology of iron-based alloys and nitriding layers, applied in metal material coating process, coating, solid-state diffusion coating, etc., can solve problems such as differences in technical means and implementation, optimize initiation and expansion behavior, and expand application range, the effect of improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] H 13 steel was processed into 80 × 30 × 10 mm thin plate samples after quenching and tempering treatment. After grinding, polishing and cleaning, they were hung in a self-made gas nitriding furnace, heated to 550 ° C, and heated in NH 3 As the medium, nitrogen potential is 0.20 level, gas nitriding treatment for 10h, and then in the furnace N 2 Rapid cooling under protected conditions. Then select projectiles with a diameter of 0.8mm, and carry out surface shot peening on the samples after nitriding treatment under the parameters of 0.15Amm strength and 200% coverage.

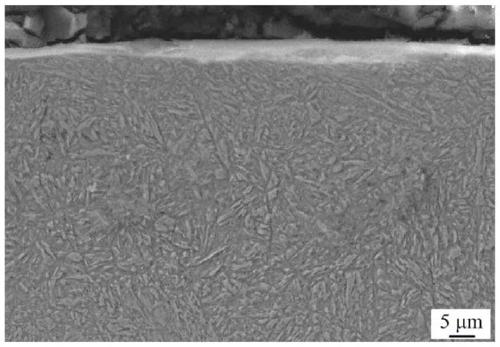

[0032] The obtained surface deformation nitriding layer structure of the inventive process is smooth, and no obvious crack occurs (see figure 1 ).

Embodiment 2

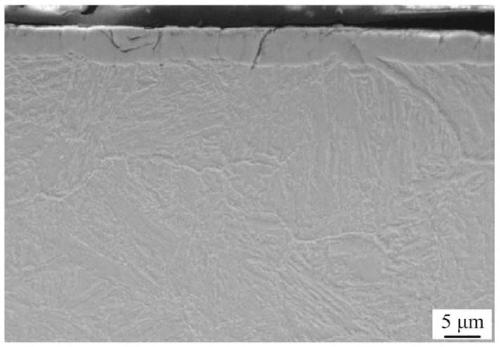

[0034] The 38CrMoAl steel was processed into a 70×30×12mm plate sample and placed in a self-made gas nitriding furnace. 3 As the medium, gas nitriding treatment at 530°C, 0.22 and 2.0 nitrogen potential levels for 20h, and then in N 2 Rapid cooling under protected conditions. Then select a projectile with a diameter of 3mm, and carry out surface shot peening on the samples after the above two nitriding processes under the parameters of 0.40Amm intensity and 300% coverage, and find that the conventional gas nitriding layer (nitrogen potential 2.0) layer is shot peened Obvious longitudinal cracks appear after treatment, some of which have been cracked along the compound layer (see figure 2 ).

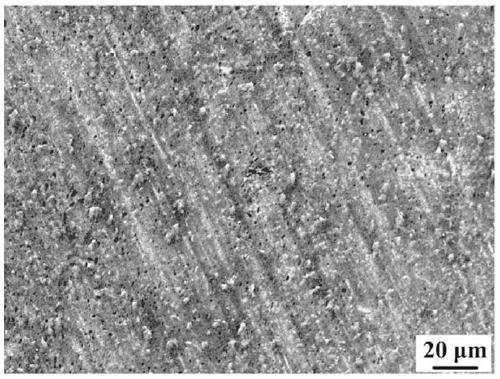

[0035] Using a pin-disk friction and wear testing machine, the two groups of samples were worn for 30 minutes under a load of 300g, and the surface wear morphology was quite different. The surface deformation nitriding layer obtained in this example has a better combination of strengt...

Embodiment 3

[0037] The preparation method of the high-strength and tough nitriding layer on the surface of the iron-based alloy in this embodiment specifically includes the following steps:

[0038] Step (1): After grinding and polishing the surface of the iron-based alloy sample, put it into a gas nitriding furnace, feed a gaseous nitrogen source, and perform gas nitriding treatment, and control the nitrogen potential at the critical value of the nitrogen potential formed by the compound layer Next, after the gas nitriding treatment is completed, furnace cooling or oil cooling is performed to obtain a nitrided layer without a compound layer;

[0039] Step (2): Perform surface shot peening treatment on the compound-free nitrided layer prepared in step (1), that is, to obtain the high-strength and tough nitrided layer on the surface of the iron-based alloy.

[0040] Wherein, the gas nitriding treatment conditions in step (1) are: the control temperature is 500° C., and the nitriding treatm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| cover factor | aaaaa | aaaaa |

| cover factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com