A method for removing traces on the surface of an automobile crankshaft

A processing method and crankshaft technology, applied in the direction of metal material coating process, coating, etc., can solve the problems of reducing the peeling off of anti-corrosion layer, and achieve the effect of speeding up efficiency, improving strength, and accelerating the speed of cooling and solidification.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

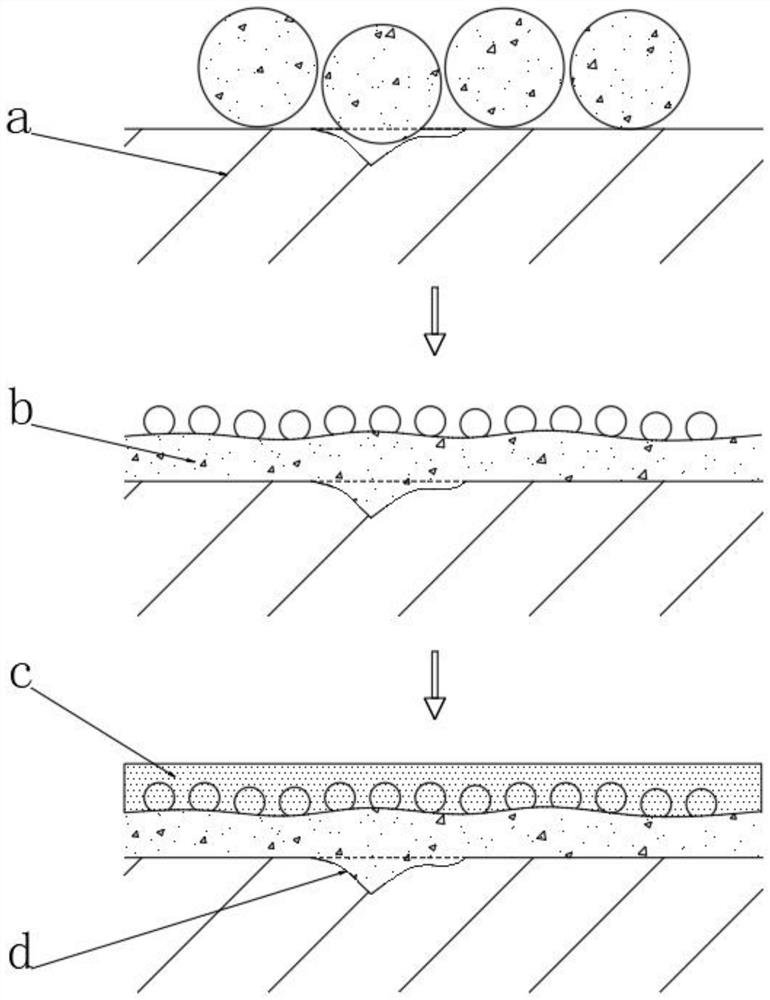

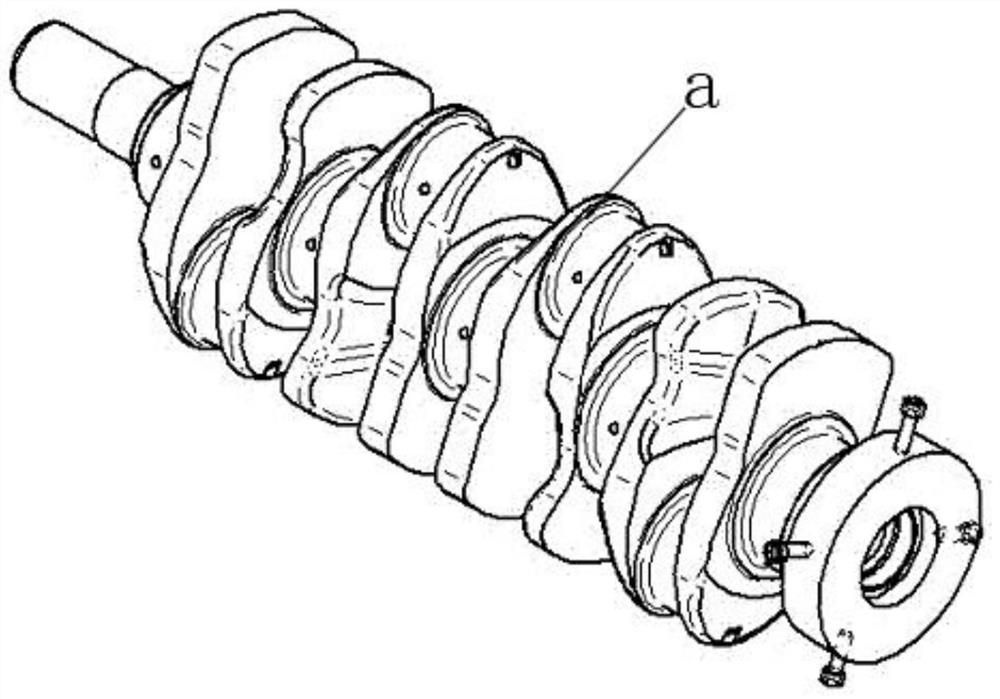

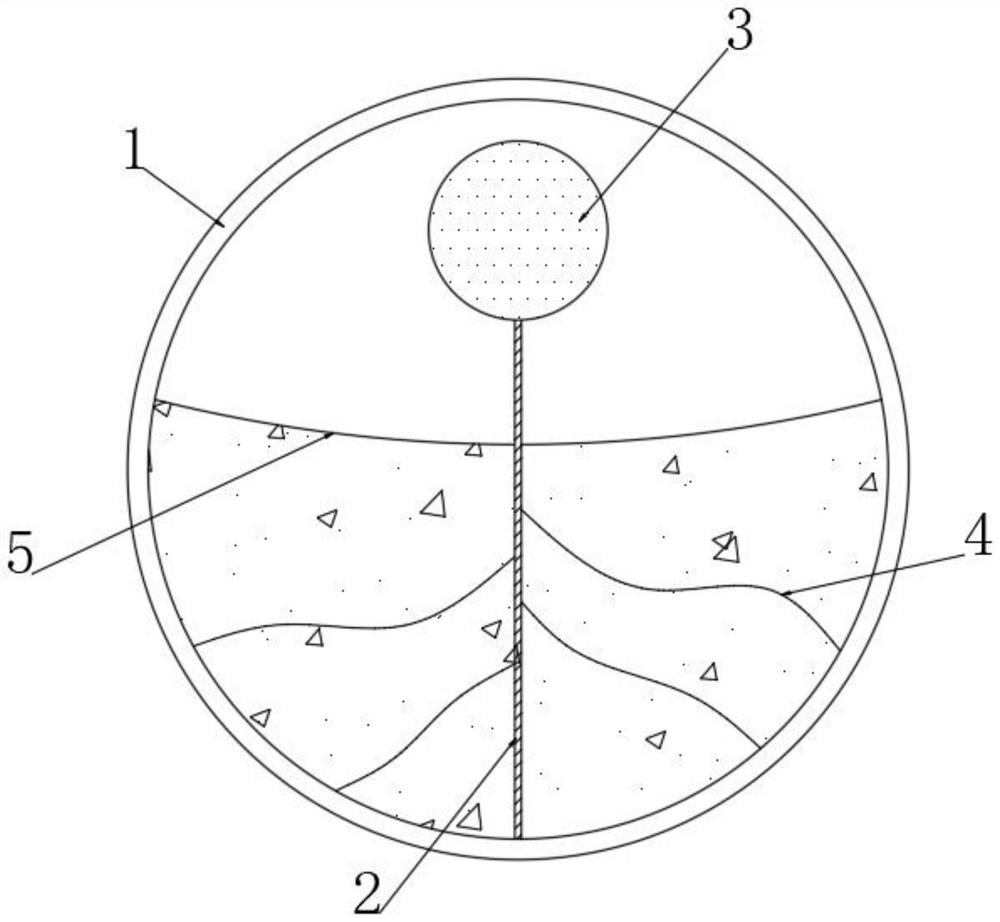

[0046] see Figure 1-2 In the figure, a represents the crankshaft, b represents the bottom layer of the repair, c represents the anti-corrosion layer, and d represents the micro-cracks on the surface of the crankshaft. A method for removing traces on the surface of an automobile crankshaft includes the following steps:

[0047] S1. First, pre-treat the crankshaft to be treated, and then dry it after treatment. The pre-treatment includes one or more of degreasing, degreasing and rust removal, which can effectively reduce the impurities on the surface of the crankshaft, so that the formed repair base layer and crankshaft The part of the surface contact is more uniform;

[0048] S2. Magnetizing the pre-treated crankshaft to make the crankshaft magnetic;

[0049] S3, then lay repair microspheres on the surface of the magnetic crankshaft to form a pre-repair layer, then adjust the thickness of the pre-repair layer until uniform, and the thickness of the pre-repair layer is 3-4mm; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com