Vacuum line and method for monitoring same

A technology of vacuum pipelines and measuring devices, which is applied in the direction of pump testing, measuring devices, and testing of machine/structural components, etc. It can solve problems such as pump unit testing that is difficult to interrupt the manufacturing process, and blockage prediction of exhaust systems that cannot be pumped.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

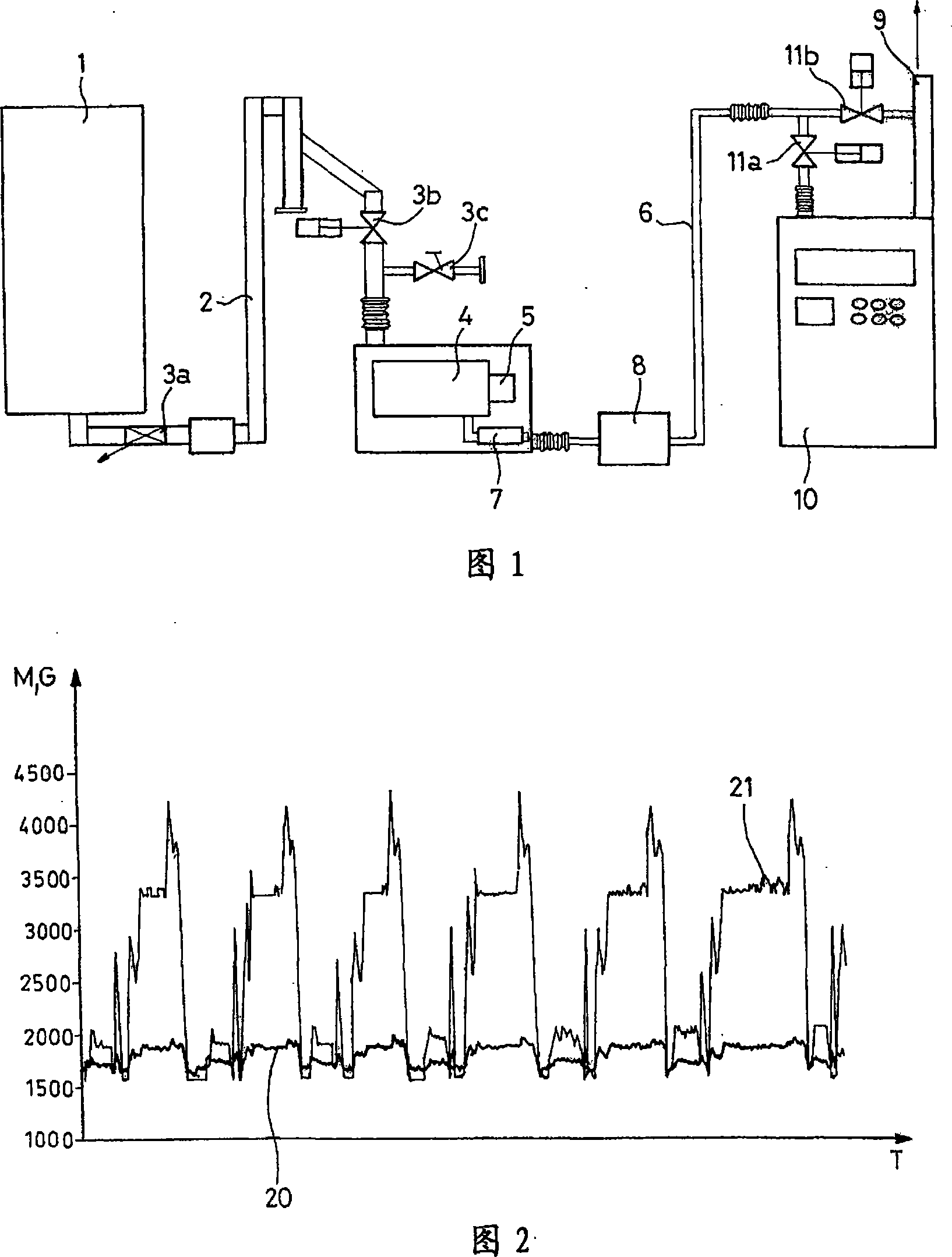

[0056] The facility shown in Figure 1 comprises a processing chamber 1 for processing substrates. For example, the process chamber can be used to perform deposition, etch, or ion implantation processes, or to perform thermal treatments, as used in the fabrication of microelectronic devices on silicon wafers. The treatment may also be micromachining of the semiconductor substrate in the manufacture of micro-electro-mechanical systems (MEMS) or micro-opto-electromechanical systems (MOEMS). The processing chamber 1 is connected to a pump body 4 driven by a motor 5 through a pipe 2 equipped with valves 3a, 3b and 3c. The pump body 4 is connected with the exhaust pipe 6 through a muffler 7 . A collector 8 may be installed on the exhaust pipe 6 to collect the solid by-products produced in the reaction. When gaseous by-products of the processes performed are not suitable to be discharged from the general exhaust port 9, the gases are vented through the treatment facility 10 using v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com