Method for manufacturing component for speaker by papermaking, copmponent for speaker by papermaking, vibrating plate for speaker, subcone for speaker, dust cap for speaker, and speaker

A manufacturing method and loudspeaker technology, applied in the direction of sensors, electrical components, diaphragm structures, etc., can solve the problem that the beating process takes a lot of time, and achieve the effect of low price and high industrial value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

[0051] (Embodiment 1)

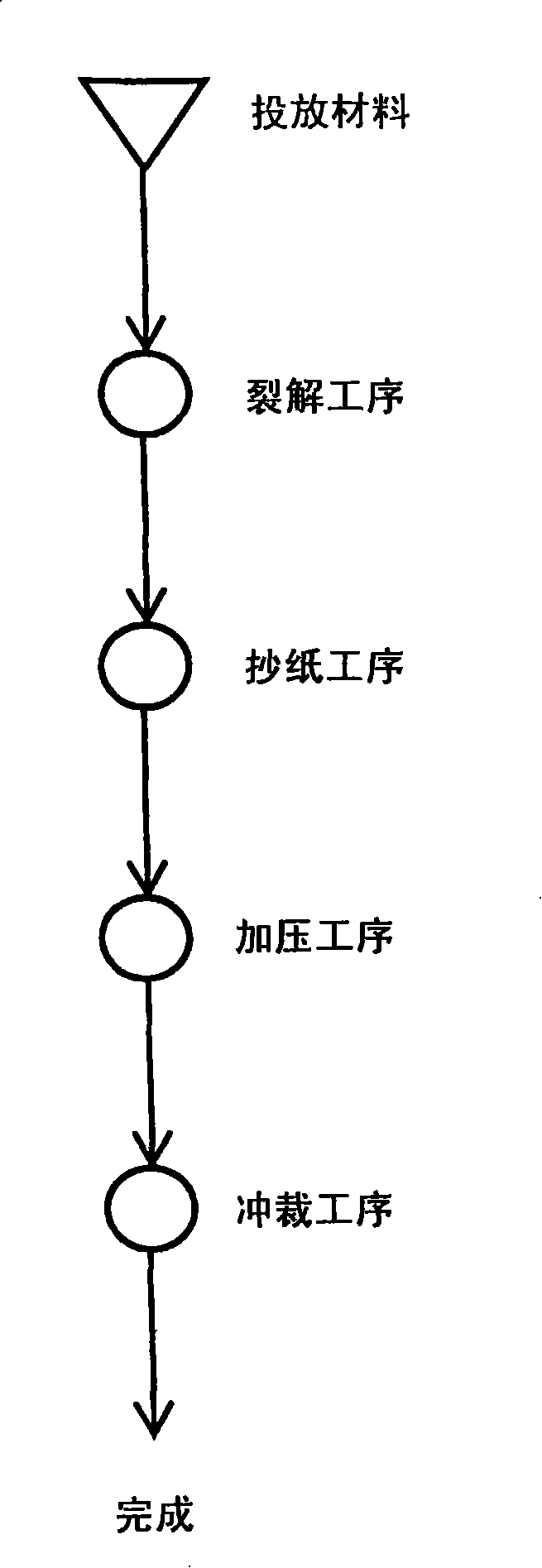

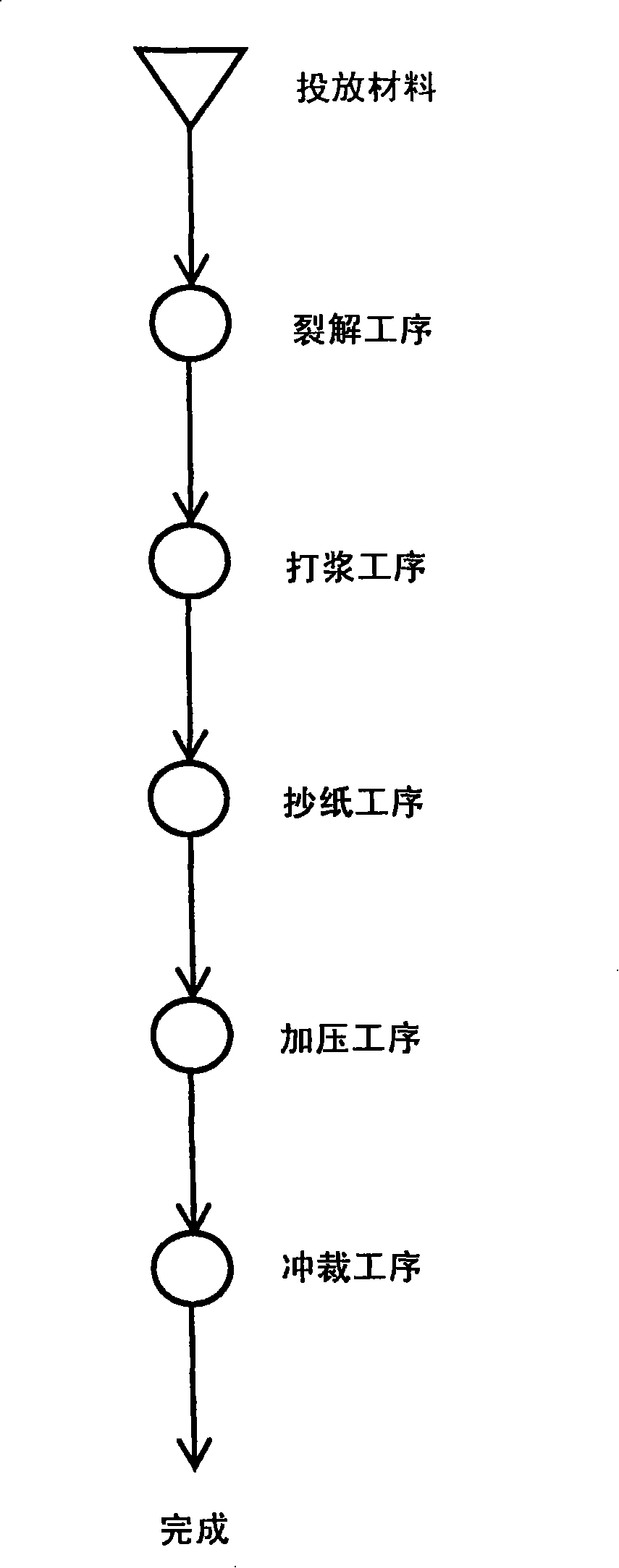

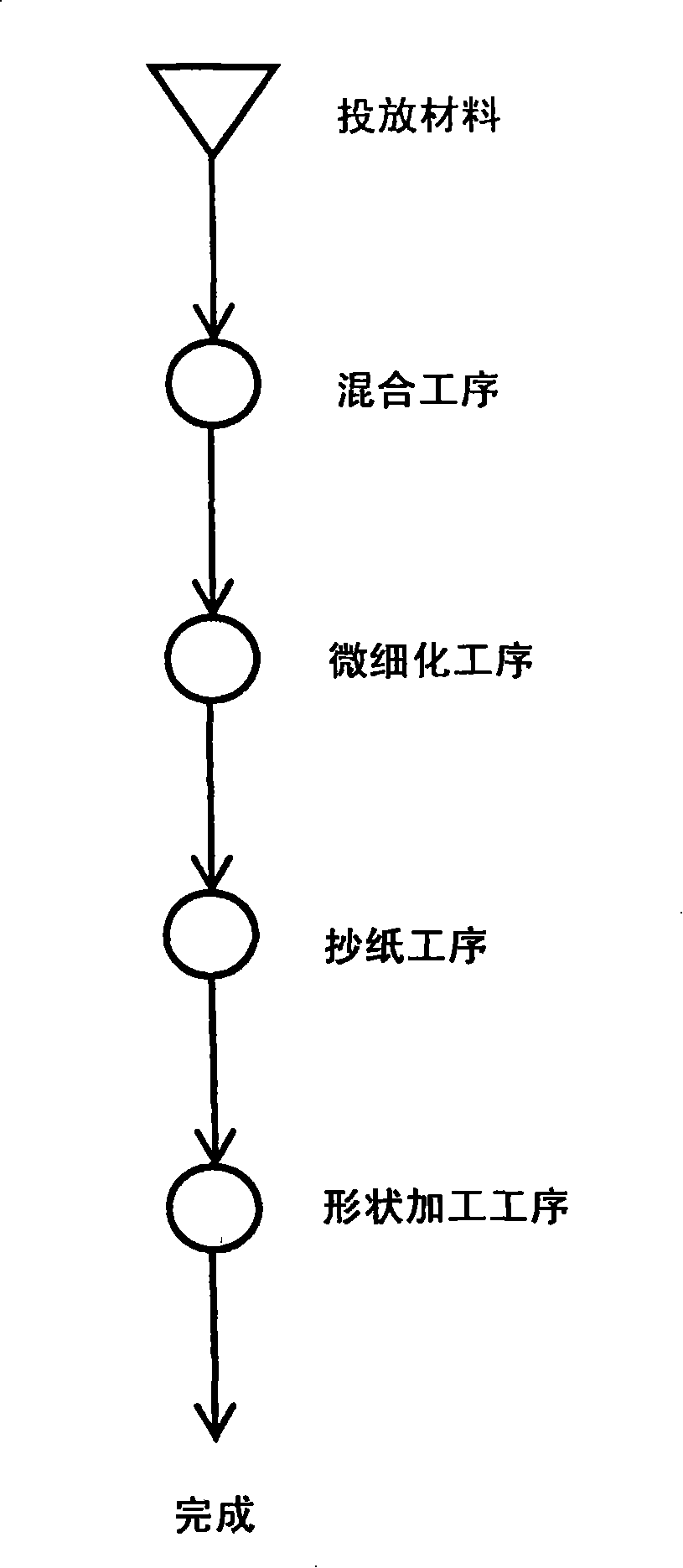

[0052] figure 1 It is a flow chart showing the manufacturing method of the paper-made diaphragm for speakers which concerns on Embodiment 1 of this invention. In Embodiment 1, the diaphragm for a speaker is demonstrated as an example of the paper-made part for speakers. The same applies to other paper-made parts for speakers, for example, an auxiliary cone for speakers, a dust cover for speakers, and other paper-made parts for speakers.

[0053] like figure 1 As shown, the material of the paper-made vibration plate for the speaker is put into a container for cracking fibers, and the fine fibers are cracked by the fiber cracking process.

[0054] Then, the defiberized material is salvaged into a metal mold and a wire mesh placed on the mold by a papermaking process, and only water is drained, and the material is deposited to form a shape as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com