Mechanical lifting device for helicopter repair and maintenance

A mechanical lifting and helicopter technology, applied to cranes, aircraft maintenance, transportation and packaging, etc., can solve problems such as time-consuming and cumbersome steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

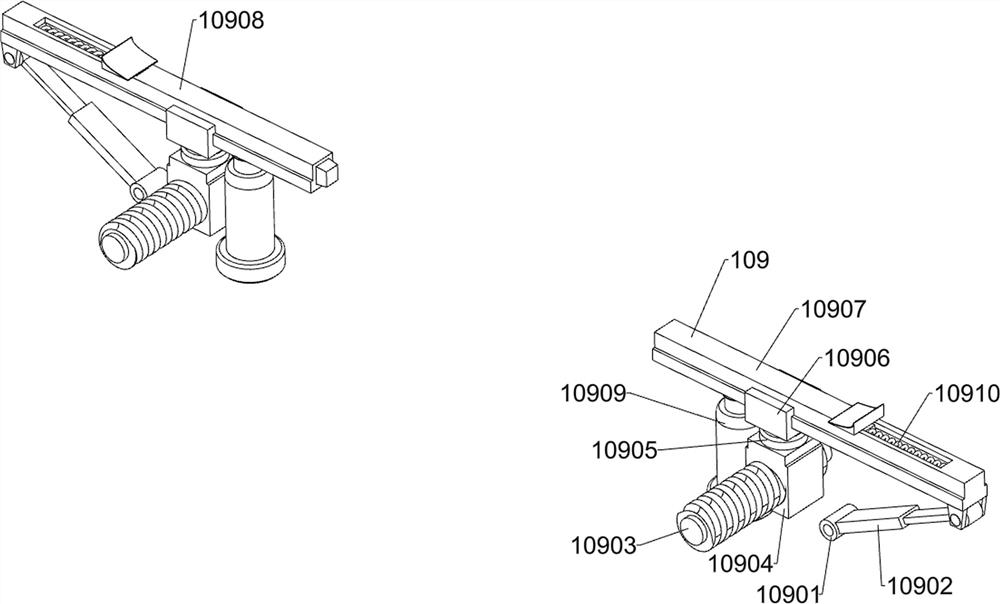

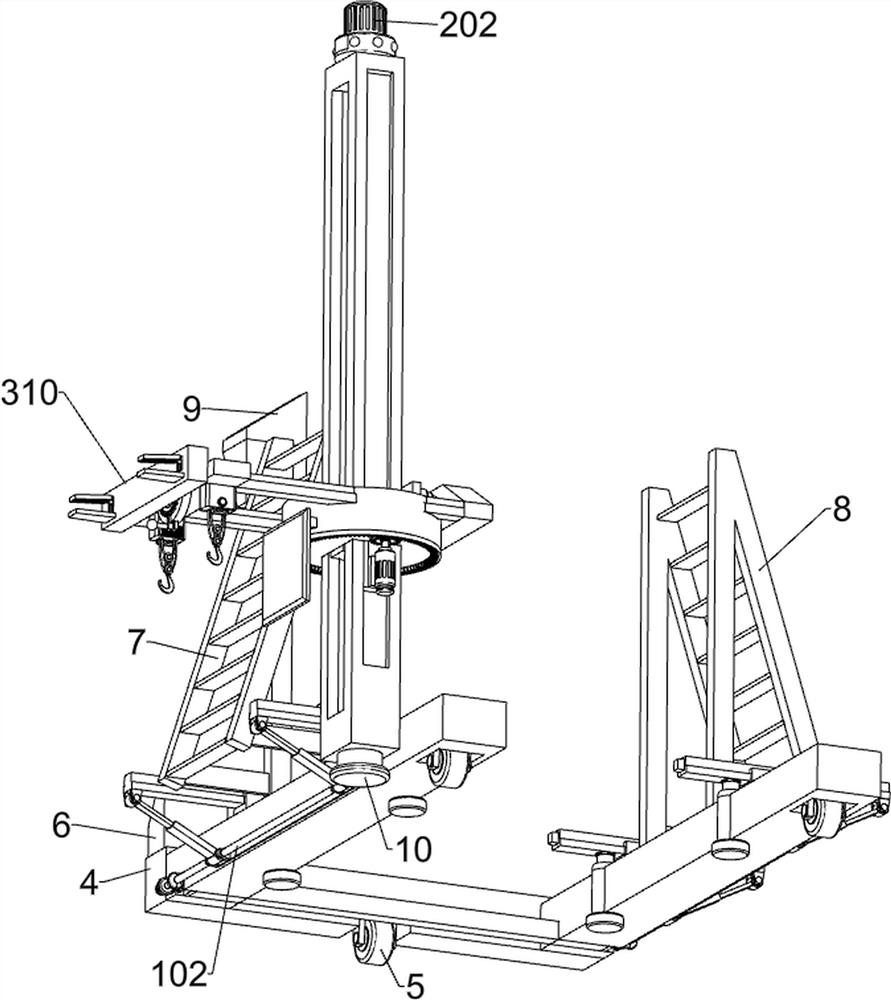

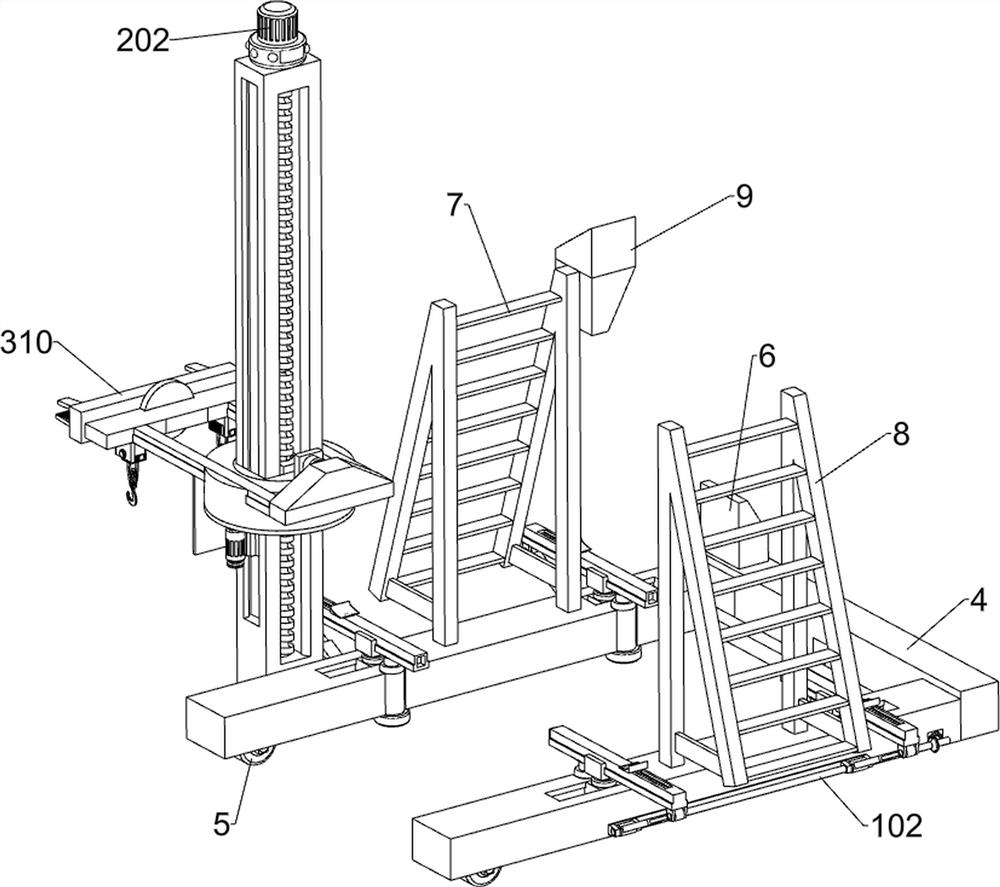

[0033] A mechanical lifting device for helicopter repair and maintenance, such as Figure 1-3 As shown, it includes a support table 4, a wheeled mobile chassis 5, a first side ladder 7, a second side ladder 8, a telescopic stand 10, a power connection assembly, a fixed lifting unit 109 and a component lifting assembly; the support table 4 The bottom is connected with a wheeled mobile chassis 5; the right side of the upper surface of the support table 4 is connected with a first side ladder 7; the left side of the upper surface of the support table 4 is connected with a second side ladder 8; the support table 4 is connected with a power connection Four sets of fixed hoisting units 109 are connected to the support platform 4; the power connection component is powered to connect four sets of fixed hoisting units 109, and the fixed hoisting units 109 are used to close the two sides of the bottom of the fuselage on the helicopter. Lifting; the right rear of the support table 4 is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com