Technique for processing municipal garbage

A municipal waste and treatment technology technology, applied in the field of municipal waste treatment technology, can solve the problems of high cost and unsatisfactory treatment effect, and achieve the effect of low cost, solving treatment problems and accelerating fermentation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

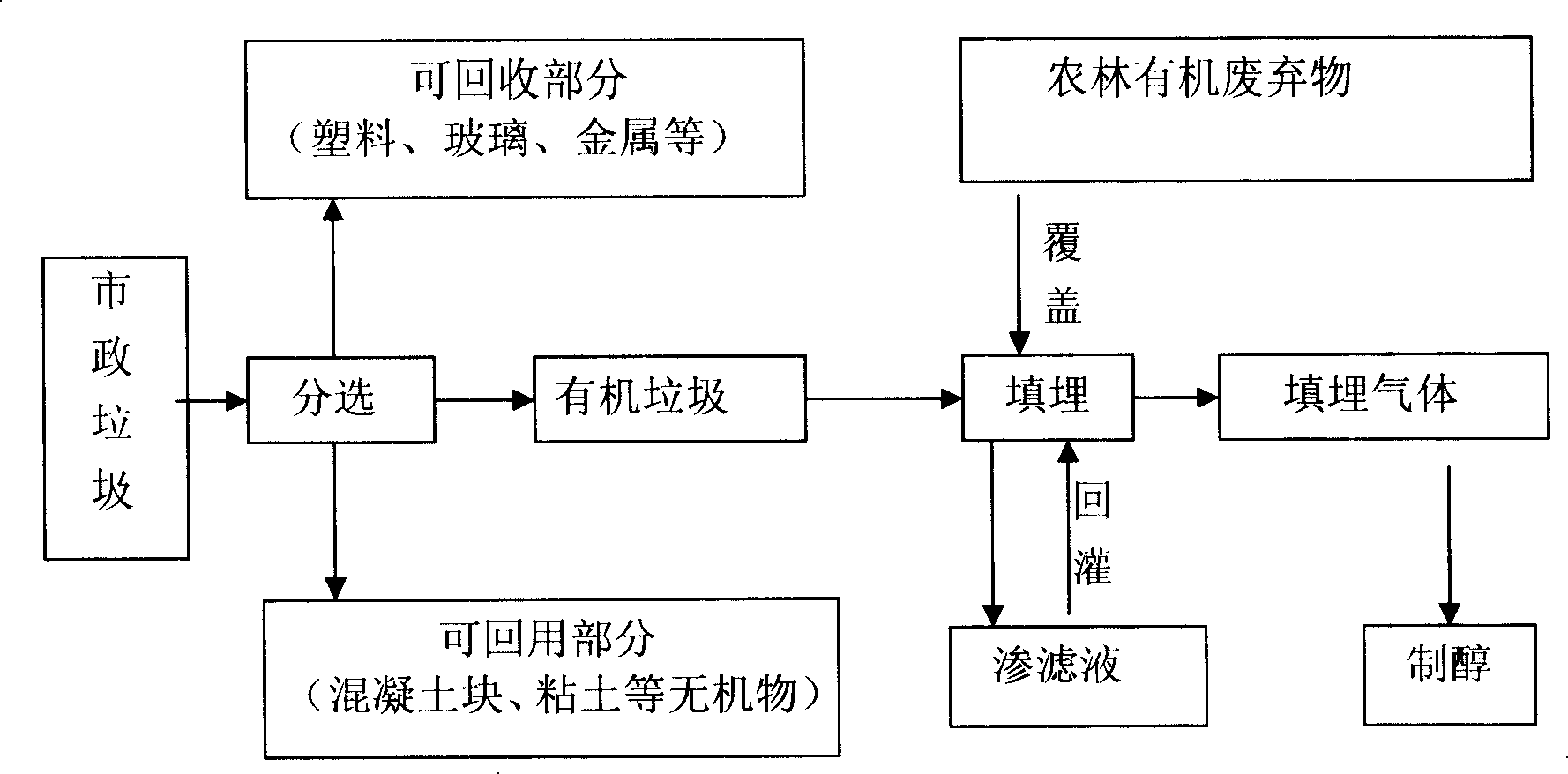

[0027] Embodiment 1: a kind of processing technology of municipal refuse, comprises the following steps successively

[0028] 1. Garbage sorting: Screen and separate the recyclable parts (plastic, glass, metal, etc.), reusable parts (concrete blocks, clay and other inorganic substances) and organic waste in the municipal waste, and the organic waste is used for standby.

[0029] 2. Backfilling of the organic part:

[0030] ① Backfill the organic waste into the lower part of the landfill pit. The landfill pit is an anti-leakage structure formed by adding an anti-leakage film, and the backfill depth of the organic waste is 3 meters. Can include several for recycling.

[0031] ② Compaction: compact the organic waste;

[0032] ③Covering of agricultural and forestry organic waste: covering the organic waste with agricultural and garden organic waste, including plant stems, branches and leaves, straw, roots, etc., with a layer thickness of 30 cm;

[0033] ④Recharge: Evenly spray ...

Embodiment 2

[0038] Embodiment 2: a kind of processing technology of municipal refuse, comprises the following steps successively

[0039] One, garbage sorting: with embodiment 1;

[0040] 2. Backfilling of the organic part:

[0041] ① Backfill the organic waste into the lower part of the landfill pit. The landfill pit is an anti-leakage structure formed by adding an anti-leakage film, and the backfill depth of the organic waste is 5 meters. Can include several for recycling.

[0042] ② Compaction: compact the organic waste;

[0043] ③Covering of agricultural and forestry organic waste: covering the organic waste with agricultural and garden organic waste, including plant stems, branches and leaves, straw, roots, etc., with a layer thickness of 5 cm;

[0044] ④ Recharging: evenly recharging the leachate pumped out from the bottom of other landfill pits, and the leachate collected every day should be recharged on the same day as much as possible;

[0045] ⑤ Covering the pure soil: Cover...

Embodiment 3

[0047] Embodiment 3: a kind of processing technology of municipal refuse, comprises the following steps successively

[0048] One, garbage sorting: with embodiment 1;

[0049] 2. Backfilling of the organic part:

[0050] ① Backfill the organic waste into the lower part of the landfill pit. The landfill pit is an anti-leakage structure formed by adding an anti-leakage film, and the backfill depth of the organic waste is 2 meters. Can include several for recycling.

[0051] ② Compaction: compact the organic waste;

[0052] ③Covering of agricultural and forestry organic waste: covering the organic waste with agricultural and garden organic waste, including plant stems, branches and leaves, straw, roots, etc., with a layer thickness of 50 cm;

[0053] ④ Recharging: evenly recharging the leachate pumped out from the bottom of other landfill pits, the leachate collected every day should be recharged on the same day as much as possible;

[0054] ⑤ Covering the pure soil: Covering t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com