Cast iron pan production equipment with recirculated cooling water device and its die casting method

A technology of circulating cooling water and production equipment, applied in the field of casting, can solve problems such as low yield, uneven product condensation temperature, and poor molding quality, so as to improve product quality and yield, uniform product condensation temperature, and solve cooling speed slow effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawing.

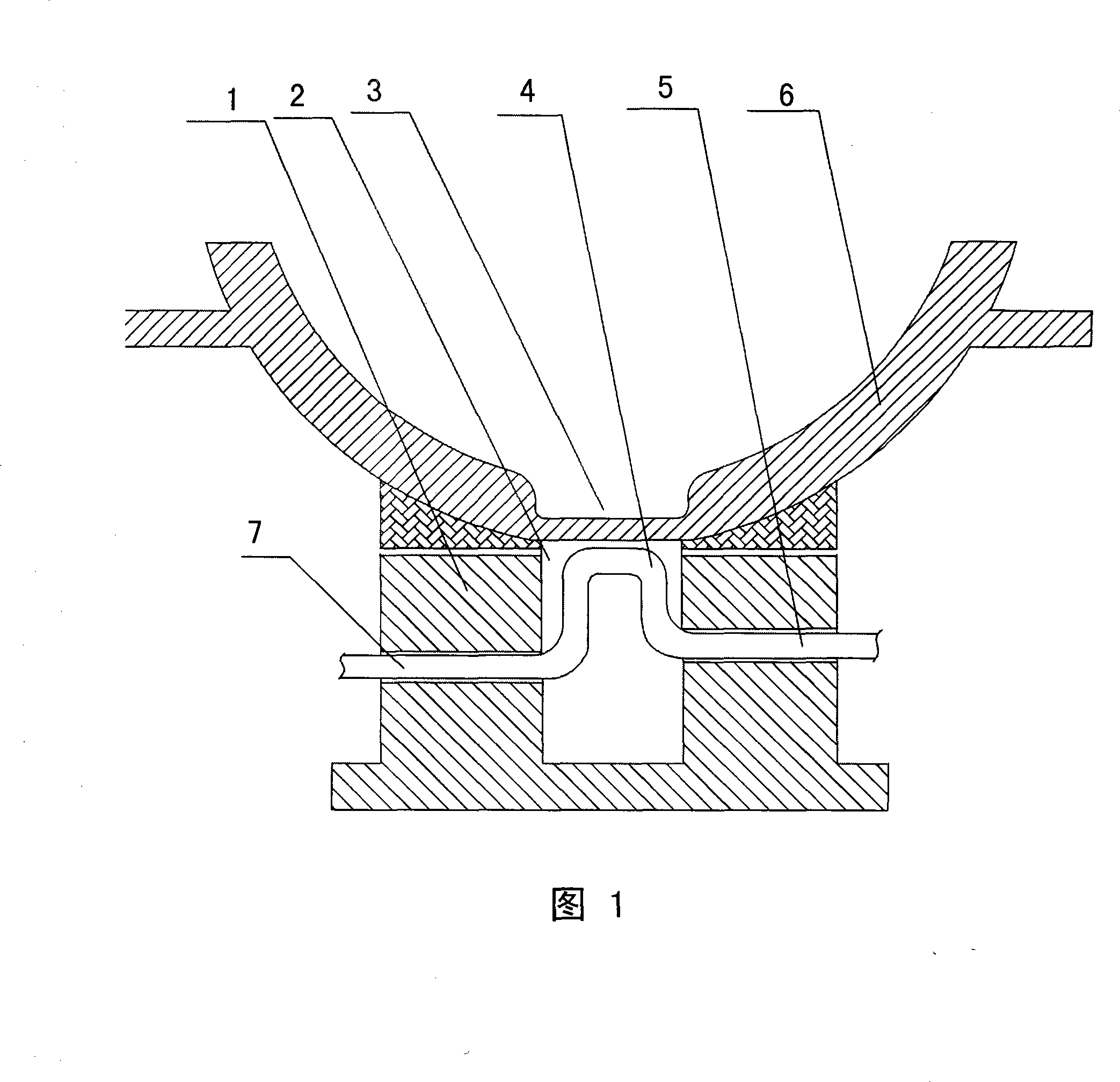

[0015] As shown in Figure 1, according to the cast iron pot production equipment of band circulating cooling water device of the present invention, comprise upper mold, lower mold, base, it is characterized in that described lower mold 6 is made into the lower mold 6 that has umbilicus 3 , the circulating cooling water device is connected with the base 1, the circulating cooling water device of the present invention is composed of the water inlet pipe section 5, the cooling pipe section 4 connected with the water inlet pipe section 5, the water outlet pipe section 7 connected with the cooling pipe section, and the inlet, It is composed of a water tank and a water pump connected by a water outlet pipe section. A round hole 2 corresponding to the size of the umbilical groove 3 of the lower mold is opened in the middle of the base 1, and cooling water pipe through holes are op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com