Orbit type gantry crane

A rail-mounted gantry crane and crane technology, which is applied to cranes, walking bridge cranes, trolley cranes, etc., can solve the problems of the complex structure and manufacturing process of the rail-mounted trolley 50, the increase in the weight of the rail-mounted trolley 50, the increase in the weight of the whole machine, etc. problems, to achieve the effect of simplifying the manufacturing process, reducing the weight of the whole machine, and reducing the burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

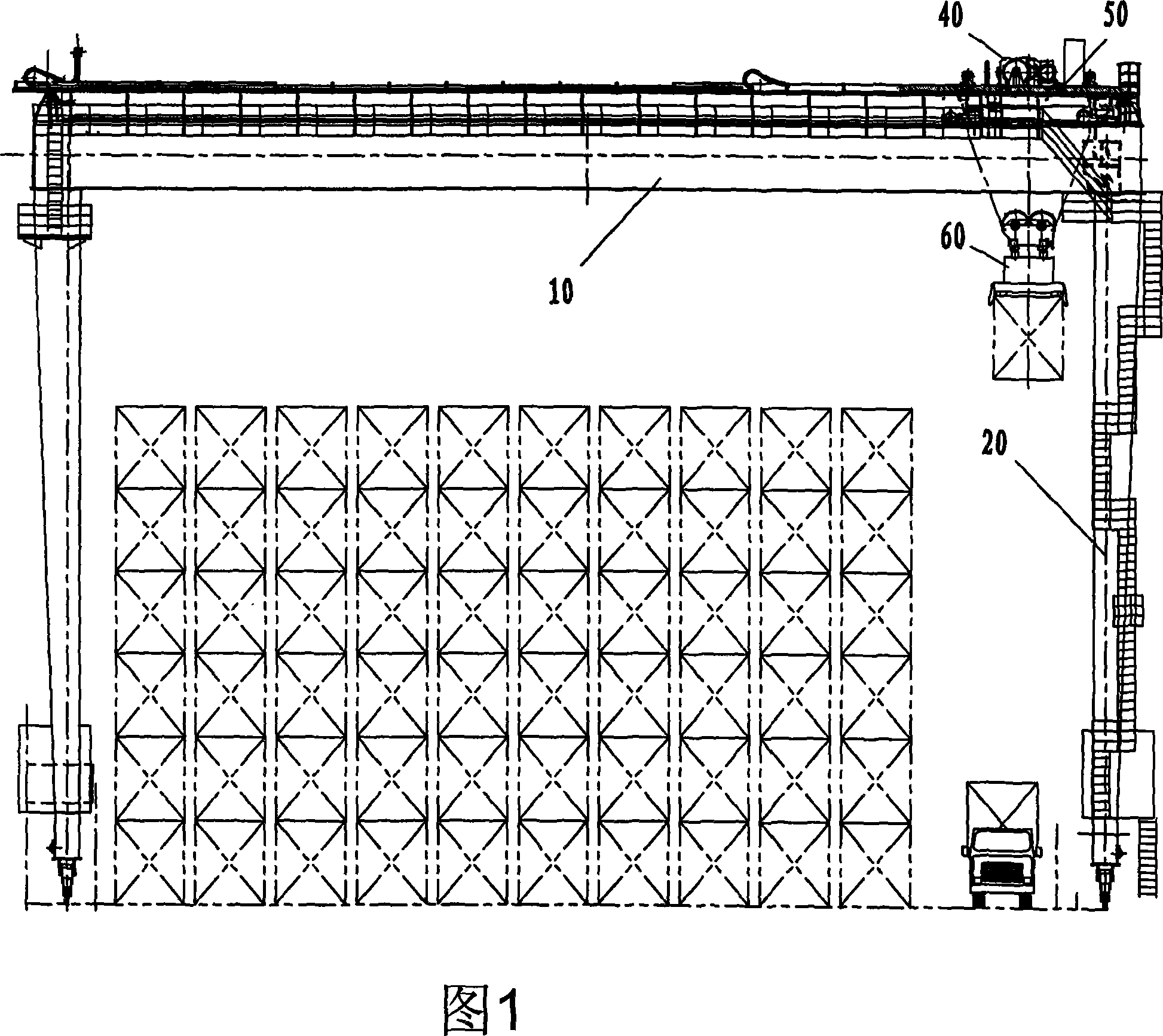

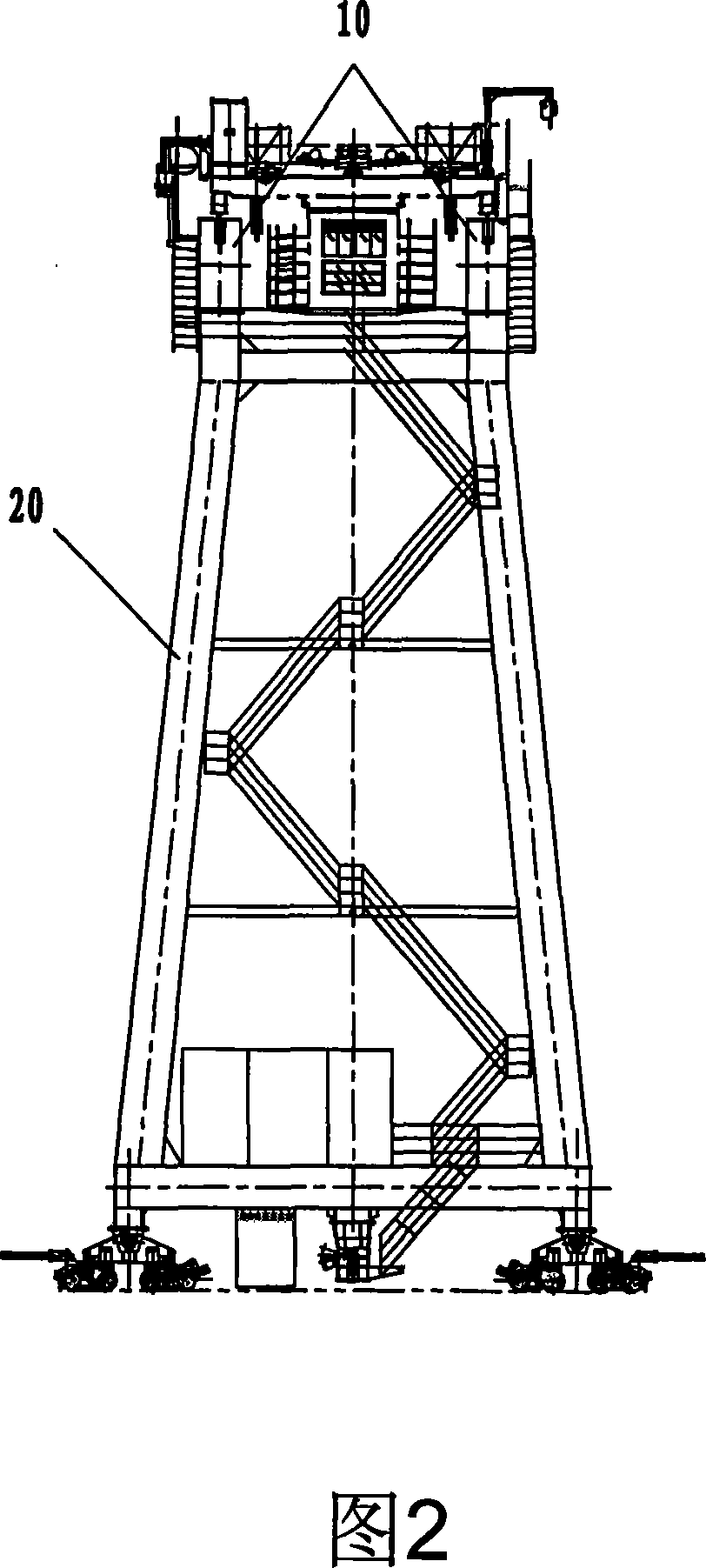

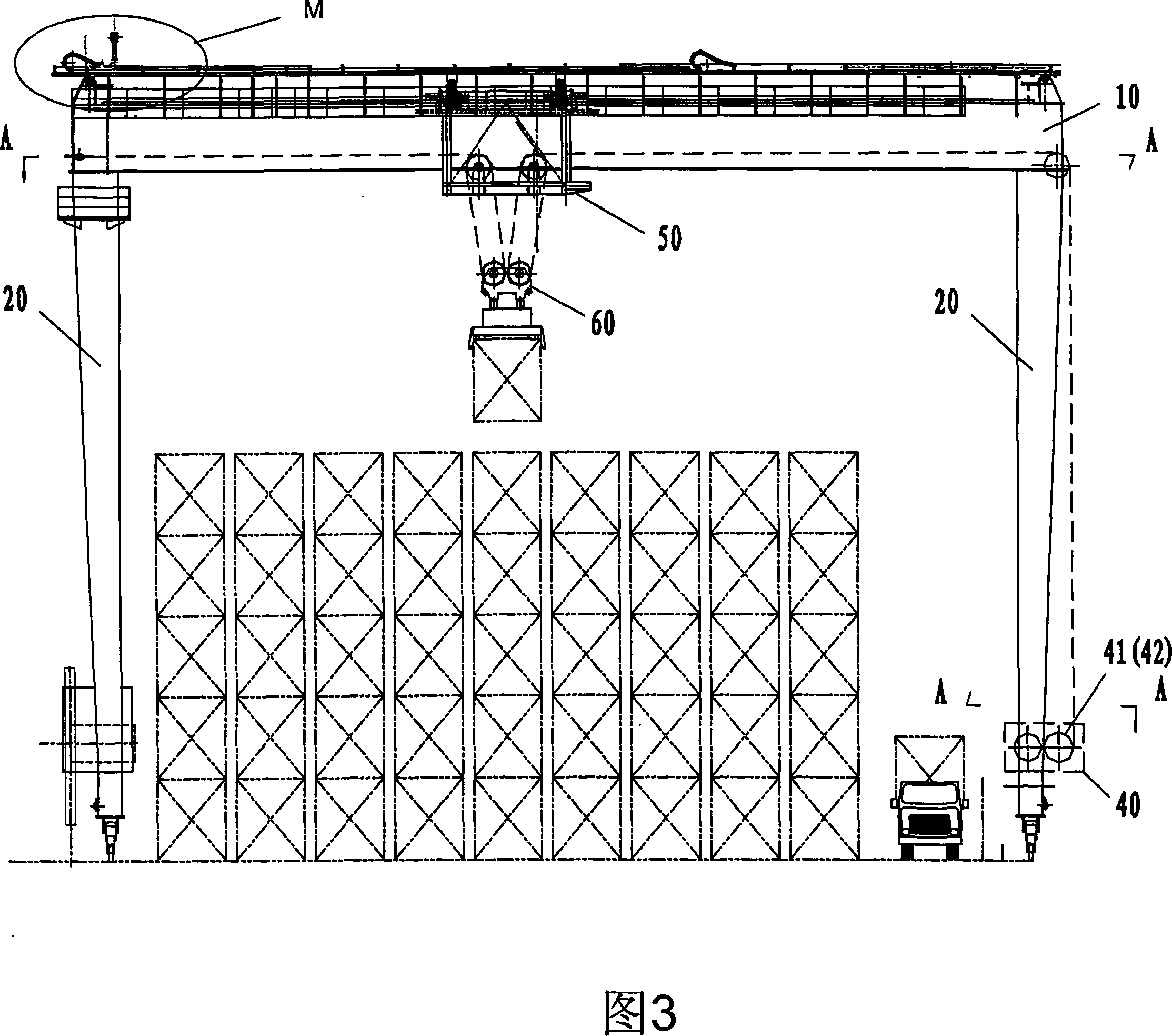

[0020] Referring to Fig. 3 and Fig. 4, described a kind of track type gantry crane, comprises girder 10, support leg 20, saddle beam 30, hoisting mechanism 40 and rail crane trolley 50, described support leg 20 supports girder 10, and described saddle The beam is installed on the lower part of the support leg 20, the track crane trolley 50 is movably connected to the girder 10 and is suitable for sliding on the girder 10, the lifting mechanism 40 is installed on the saddle beam 30, and the steel wire rope 41 drawn from the lifting mechanism 40 , 42 are connected to the pulleys on the rail crane spreader 60 after passing through the relevant pulley block. The girder 10 is a single girder structure, and the top of the supporting leg 20 has a mounting surface 21. The ends are connected and fixed to the girder 10 through the insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com