Multifunctional cleaning appliance integrated machine

A cleaning utensil and multi-functional technology, which is applied in the field of an integrated cleaning utensil machine with a washbasin, can solve the problems of hindering the flexible rotation of the washbasin, hindering laundry, drying, and high sales prices, thereby increasing the layout effect and the production cost. The effect of low and low transportation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

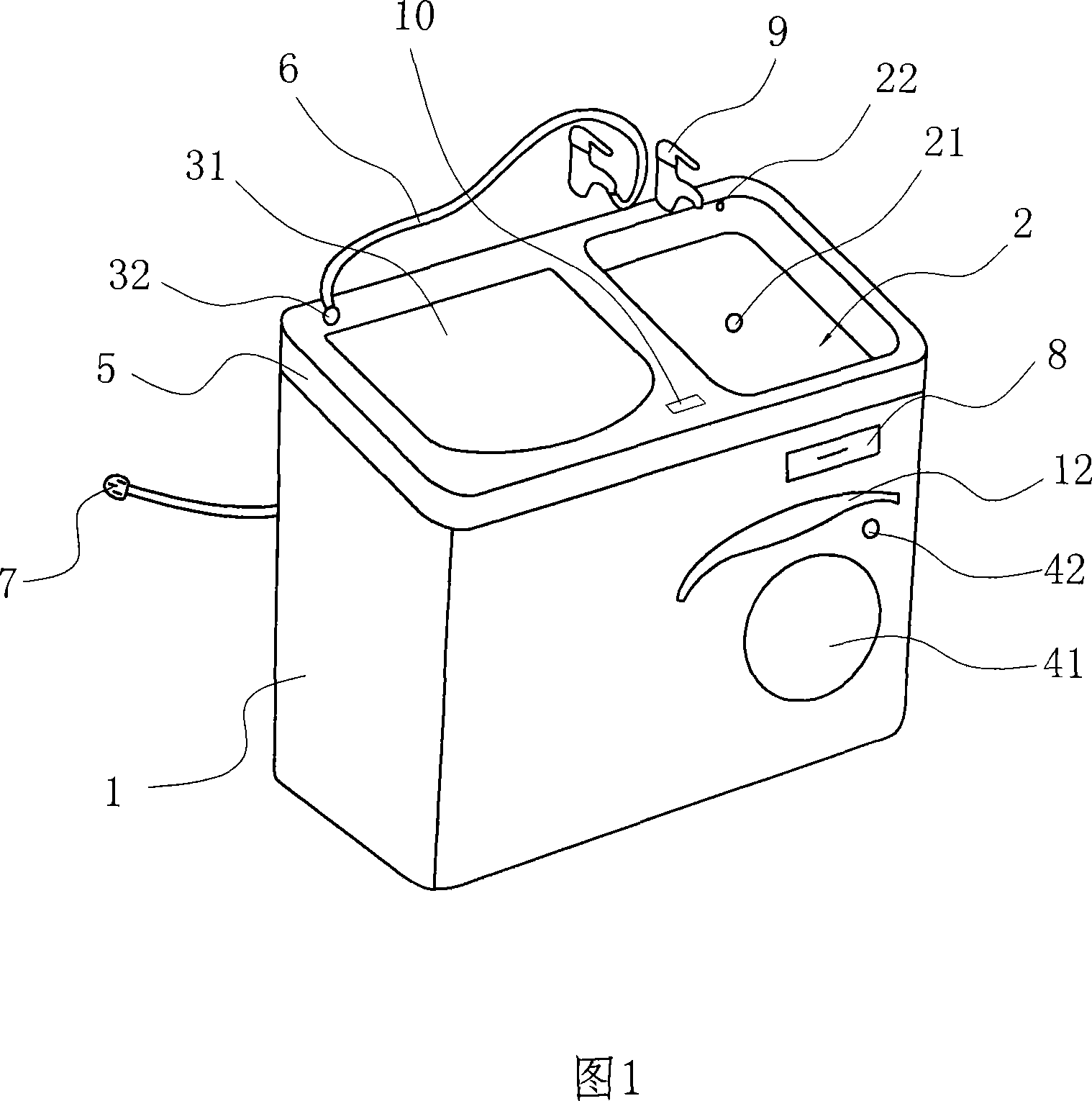

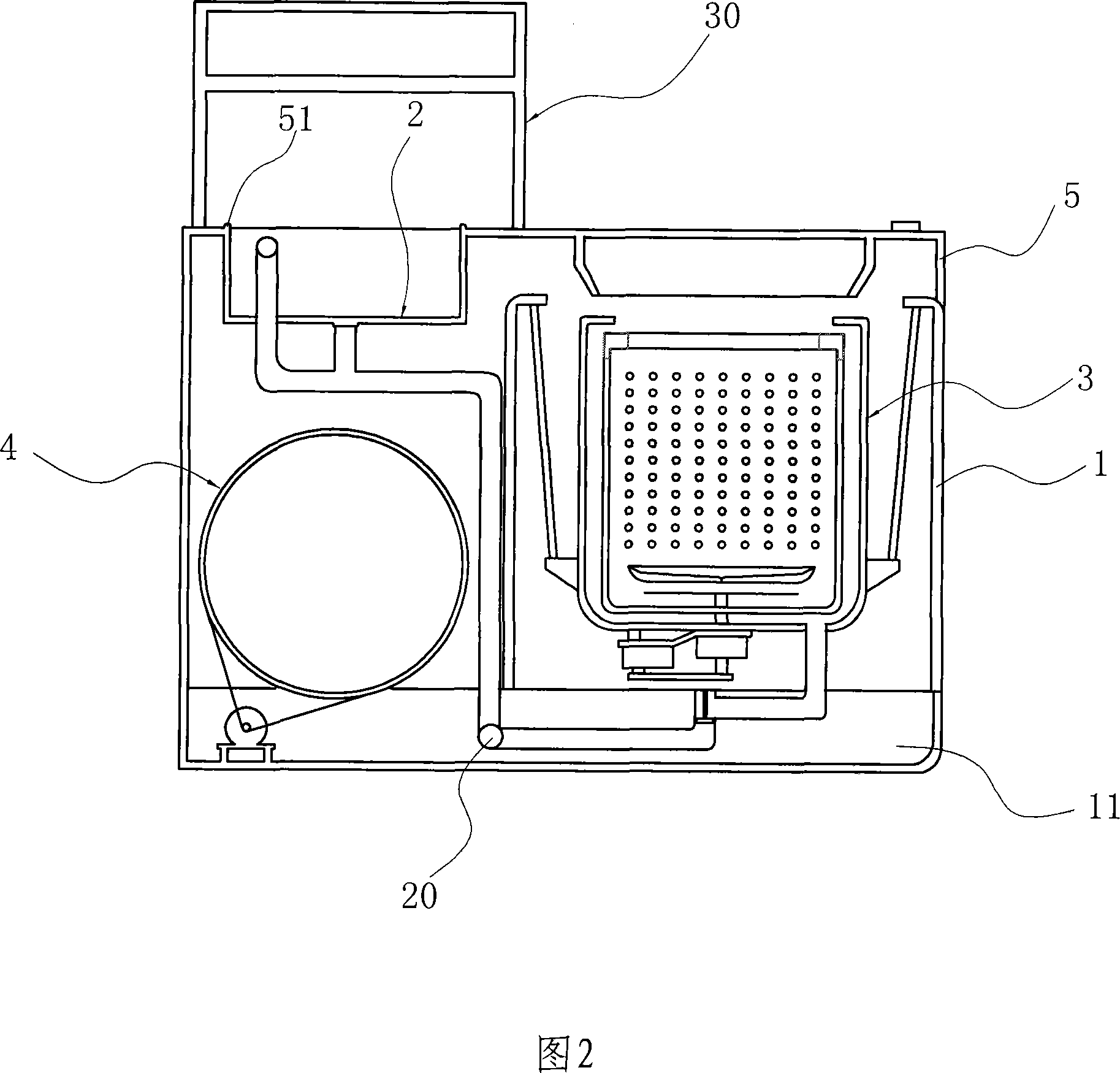

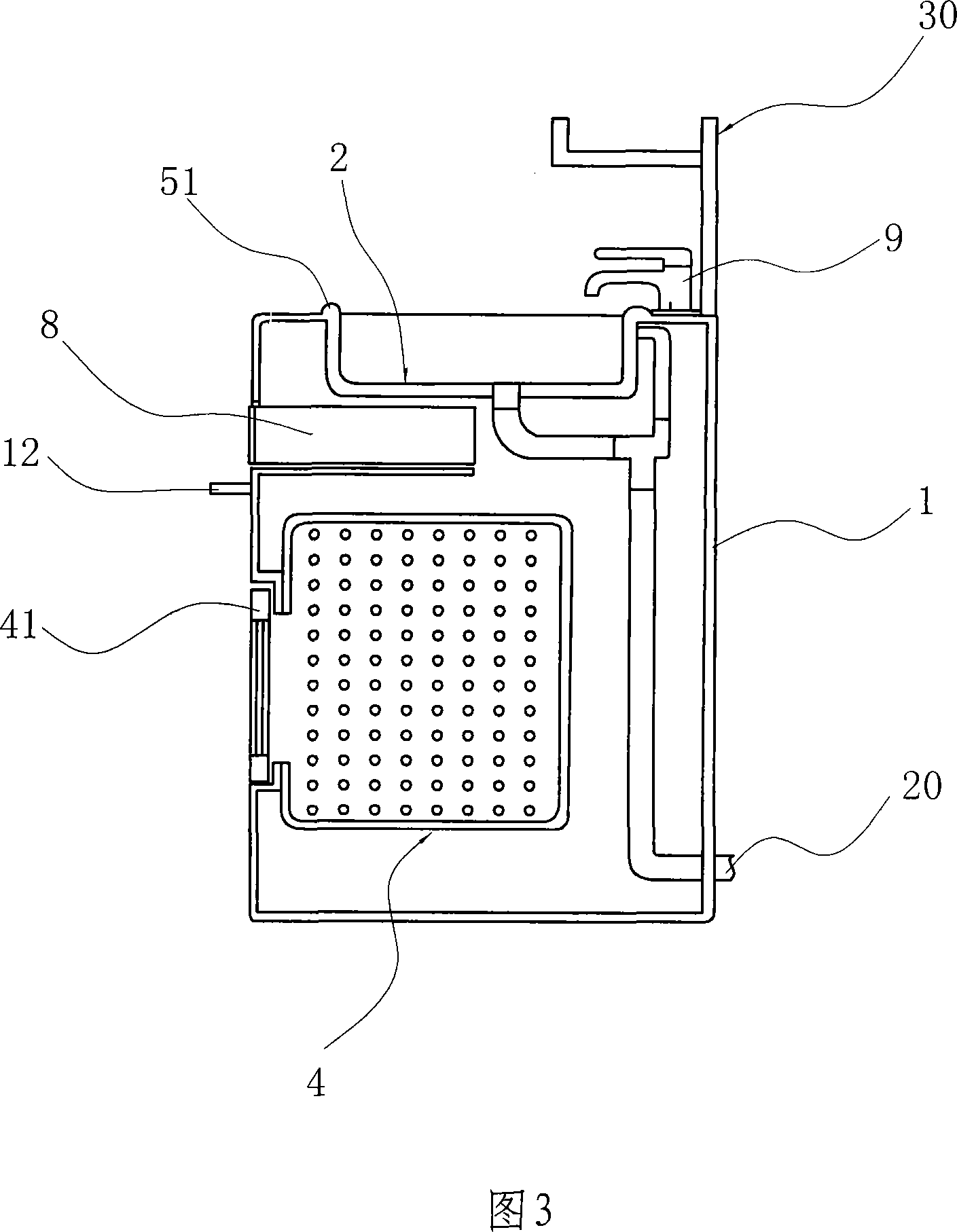

[0024]Embodiment 1, as shown in Figures 1 to 3, the integrated cleaning appliance includes a cabinet 1, a washbasin 2, and a fully automatic washing machine main body 3 and a drum dryer main body 4 placed side by side in the cabinet. The main body of the washing machine 3 adopts a pulsator type or twisting type full-automatic washing machine inner core, and the main body of the drum clothes dryer 4 then adopts the inner core of the front-opening type drum drying laundry. More details. The upper part of the cabinet 1 is provided with a surrounding frame 5 , and the bottom is fixed on a base 12 , that is, in this embodiment, the casing of the all-in-one machine is formed by the cabinet 1 , the surrounding frame 5 and the base 11 . Of course, the casing and the base can also be made in one piece. A cover plate 31 corresponding to the main body 3 of the automatic washing machine is hinged on the above-mentioned surrounding frame 5, and a control switch and a water inlet 32 of t...

Embodiment 2

[0028] Embodiment 2, as shown in FIG. 4 , is different from the above-mentioned first embodiment in that: an instant hot water heater is provided in the box body 1 to provide hot water for the washbasin 2 and the main body 3 of the fully automatic washing machine. Device 50, the instant hot water heating device adopts conventional technology, its cold water inlet hole is connected to the water inlet port 32 through the water pipe 60, and the hot water outlet of the instant hot water heating device 50 is passed through the first hot water pipe 40 is connected to the hot water inlet of water tap 9, and is sent in the revolving barrel of fully automatic washing machine main body 3 by the second hot water pipeline 70 simultaneously. The water inlet interface 32 sends cold water to the drum of the fully automatic washing machine main body 3 through a cold water pipe 80, and a cold water control valve 90 is installed on the cold water pipe. The control panel of the instant water hea...

Embodiment 3

[0029] The third embodiment differs from the second embodiment above in that: the control panel of the instant water heating device 50, the control switch of the main body of the fully automatic washing machine, and the control switch panel 42 of the drum dryer are uniformly arranged on the On the same control panel, the control panel is installed on the surrounding frame 5, as shown in FIG. 1 . This is more convenient to operate and is also conducive to the overall shape design.

[0030] Obviously, with the above-mentioned all-in-one machine, people can use the washbasin for washing, use the fully automatic washing machine for laundry, and use the drum dryer for drying clothes at the same time. Moreover, hot water can be obtained by using the instant hot water heating device, and the height of the dryer is generally lower than that of the corresponding washing machine, so that an all-in-one machine of different heights can be produced to meet the needs of students of differen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com