Method and device for anchoring changeable prestressing force of suspension bridge

A prestressing and replacement technology, applied in bridges, bridge parts, bridge maintenance, etc., can solve problems such as difficult to judge prestressed steel tendons, unreliable corrosion protection, difficult detection and maintenance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

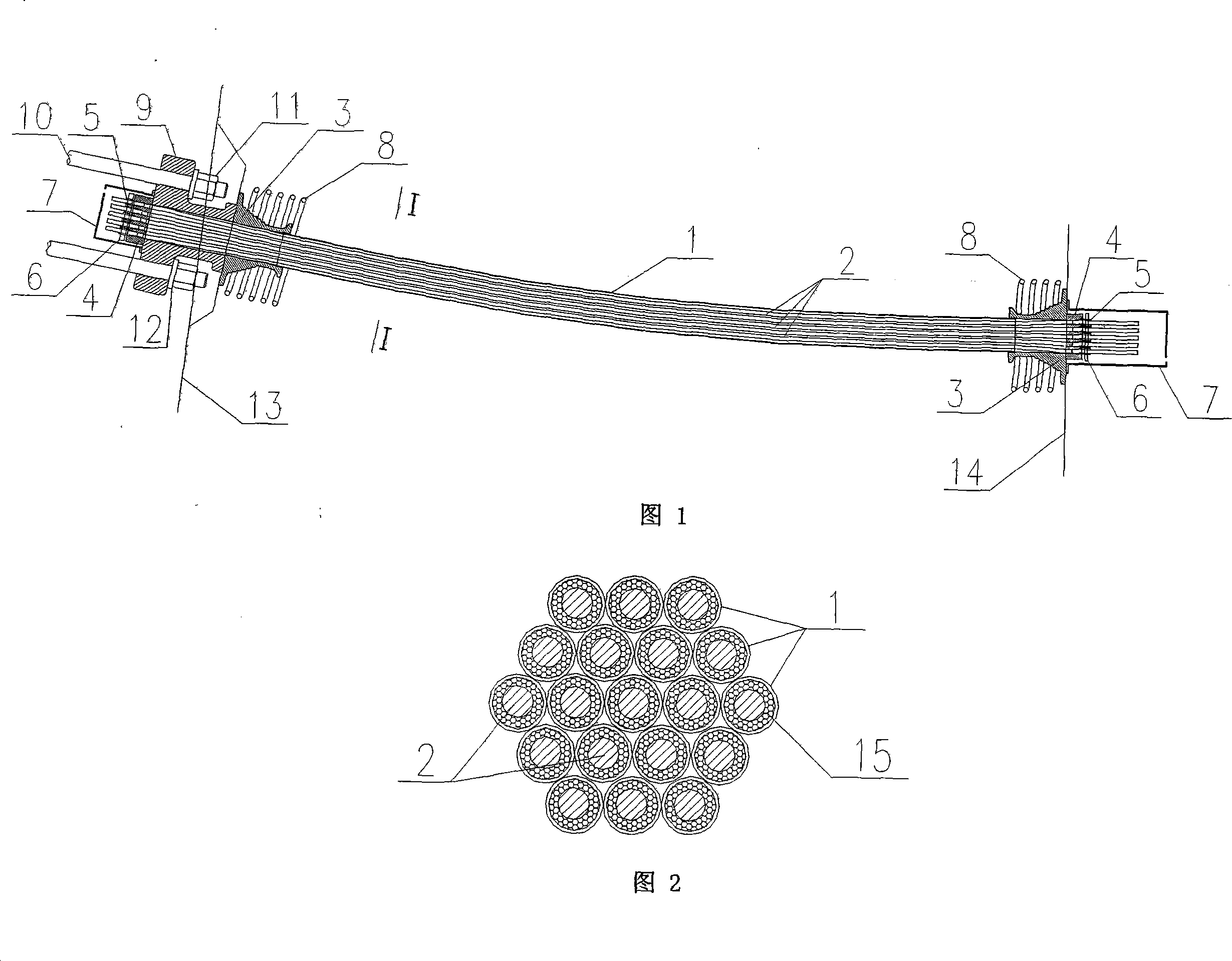

[0070] A replaceable prestressed design method for suspension bridge anchorage includes two preconditions that should be met in the design, a judgment condition for later cable replacement and a cable replacement method:

[0071] 1. Two prerequisites that must be met in the design phase

[0072] Assume that the maximum tension of the main cable strand corresponding to a bundle of prestress is P in the bridge operation stage (the bridge design code is called the permanent state), and the tension of the main cable strand is P′ when the bridge is overhauled and replaced by controlling the passage of the main cable strand , the effective anchoring force of the prestressed beam is F, and the number of strands of the prestressed beam is n. In order to achieve replaceability, two conditions should be met:

[0073] 1) The whole bundle of prestress meets the safety conditions of the permanent state of the main cable strand

[0074] F>k*P (Formula 1)

[0075] Where k is the safety fac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com