Floor and ceiling fixing device

A technology for fixing devices and ceilings, which is applied to floors, building components, buildings, etc. It can solve problems such as unfavorable impacts on the opening time of enterprises, business obstacles, and loss of site costs, and achieve good locking effects, lighten work intensity, and facilitate maintenance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

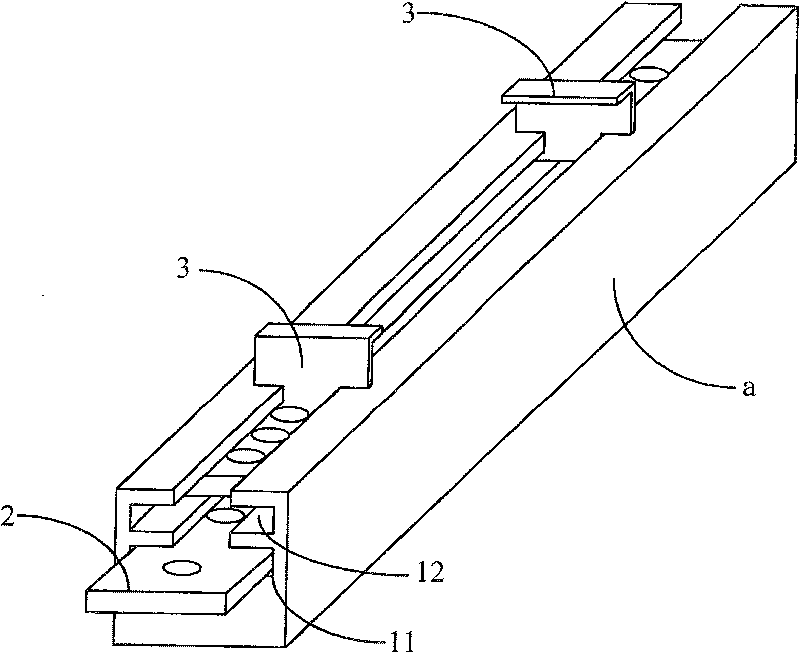

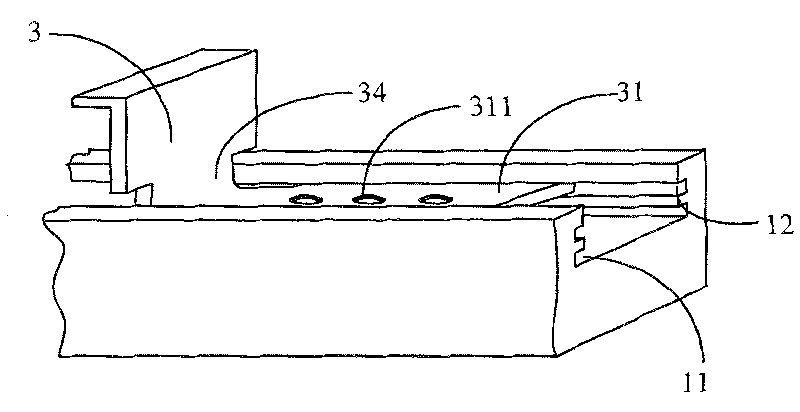

[0058] figure 1 Shown is a specific embodiment of the present invention, including a beam a for bearing the floor or ceiling, the beam a is a columnar body, and the surface of the columnar body is provided with a plurality of superimposed by the lower chute 11 and the upper chute 12. Layer chute group. The lower chute 11 and the upper chute 12 are both linear chute whose inner width dimension is larger than the width dimension of the slot. The slot of the lower chute 11 is located at the bottom of the upper chute 12 . A sliding piece 2 matched with the lower sliding groove 11 is arranged in the lower layer chute group, and the sliding piece 2 is provided with a plurality of screw holes and bolts. When the bolts pass through the screw holes on the sliding piece 2 and are tightened, the end of the bolt touches the bottom of the lower chute 11, and the sliding piece 2 can be fixed. 11 swipe arbitrarily.

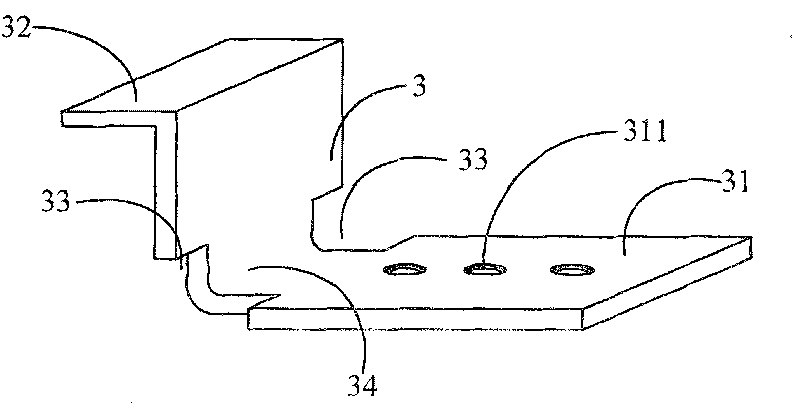

[0059] A bending and fixing plate 3 is arranged in the upper chute 11 ...

Embodiment 2

[0066] Figure 8Shown is another specific embodiment of the present invention. In the figure, the beam a is composed of a plurality of chute positioning connecting rods 1 connected axially from end to end, and the chute positioning connecting rod 1 is a cylindrical body. The connection between the adjacent sliding groove positioning connecting rods 1 is realized by the sliding piece 2 provided in the lower sliding groove 11 . The structure of the chute positioning connecting rod 1 is as follows Figure 9 shown. In the figure, the structure of the chute positioning connecting rod 1 is the same as that of the beam in the first embodiment, with a lower chute 11 and an upper chute 12 . The upper chute 12 is mainly used to set the bending and fixing plate and carry the floor or ceiling. The connection between the chute positioning connecting rods 1 is as follows: two ends of a sliding piece 2 are respectively set in the lower chute 11 of two adjacent chute positioning connecting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com