Pig machine chain transmission device

A technology of transmission device and machine chain, which is applied in the direction of transmission device, hoisting device, portable lifting device, etc., can solve the problems of asynchronous operation of the driving and driven wheels and chain belt, and achieve stable and reliable operation, reasonable structural design, extended The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

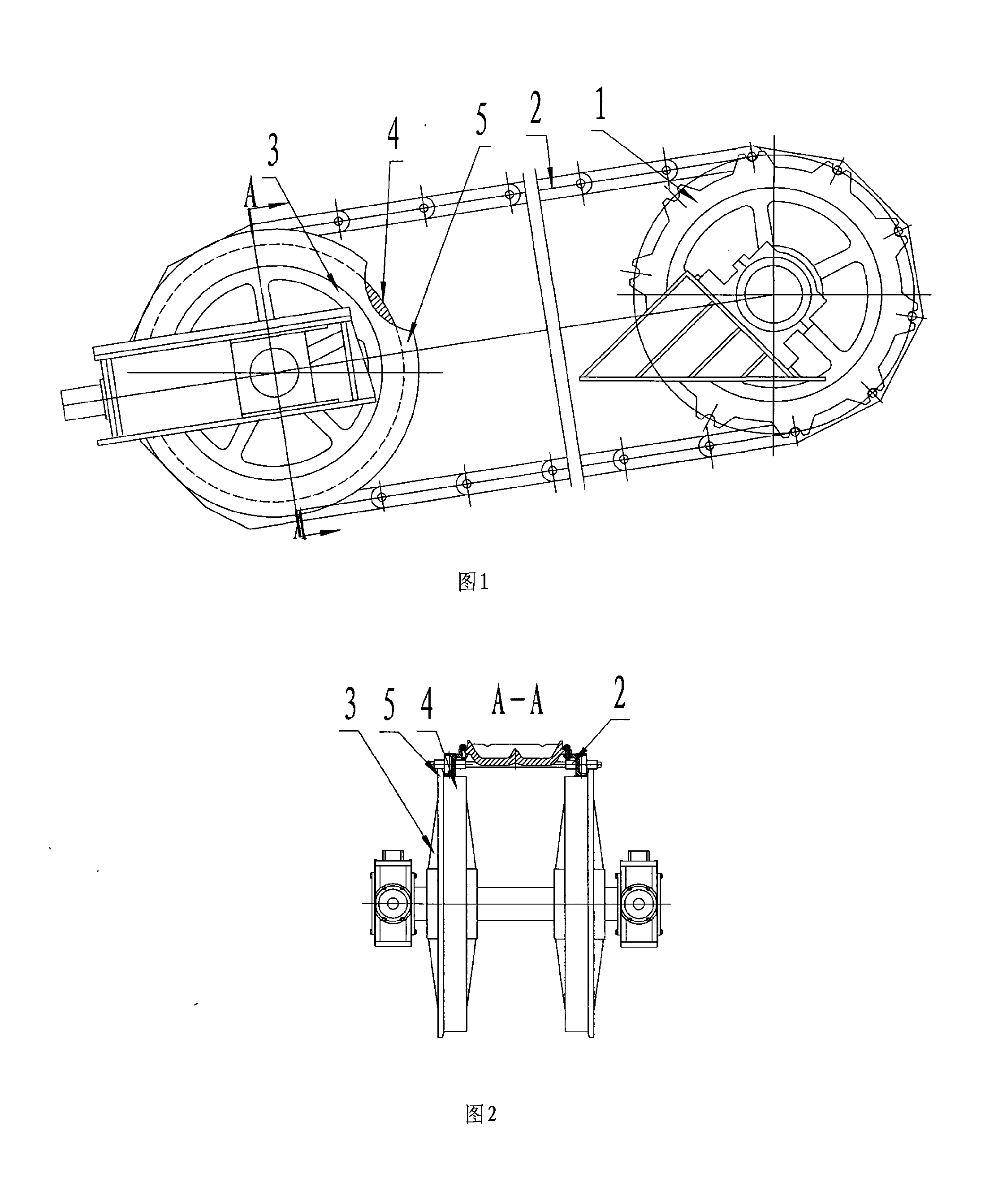

[0009] Embodiments of the present invention will be described below in conjunction with the accompanying drawings.

[0010] The cast iron machine chain transmission device comprises a driving wheel 1, a driven wheel 3 and a chain belt 2. The driven wheel 3 adopts an anti-dropping belt structure, and its gear teeth have no gear teeth, but a smooth circumferential rail edge 4 is designed, and a circle of protruding retaining rings 5 is designed on the outer edge of the peripheral rail edge 4 .

[0011] When the driving wheel 1 drives the driven wheel 3 to run through the chain belt 2, the driven wheel 3, the chain belt 2 and the driving wheel 1 can always keep running synchronously, and the belt drop phenomenon does not occur any more.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com