Linear guide rail for a linear guide system provided with a coolant slot

A linear guide rail and linear guidance technology, applied in the direction of linear motion bearings, bearing cooling, manufacturing tools, etc., to achieve the effect of minimizing heat and eliminating deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

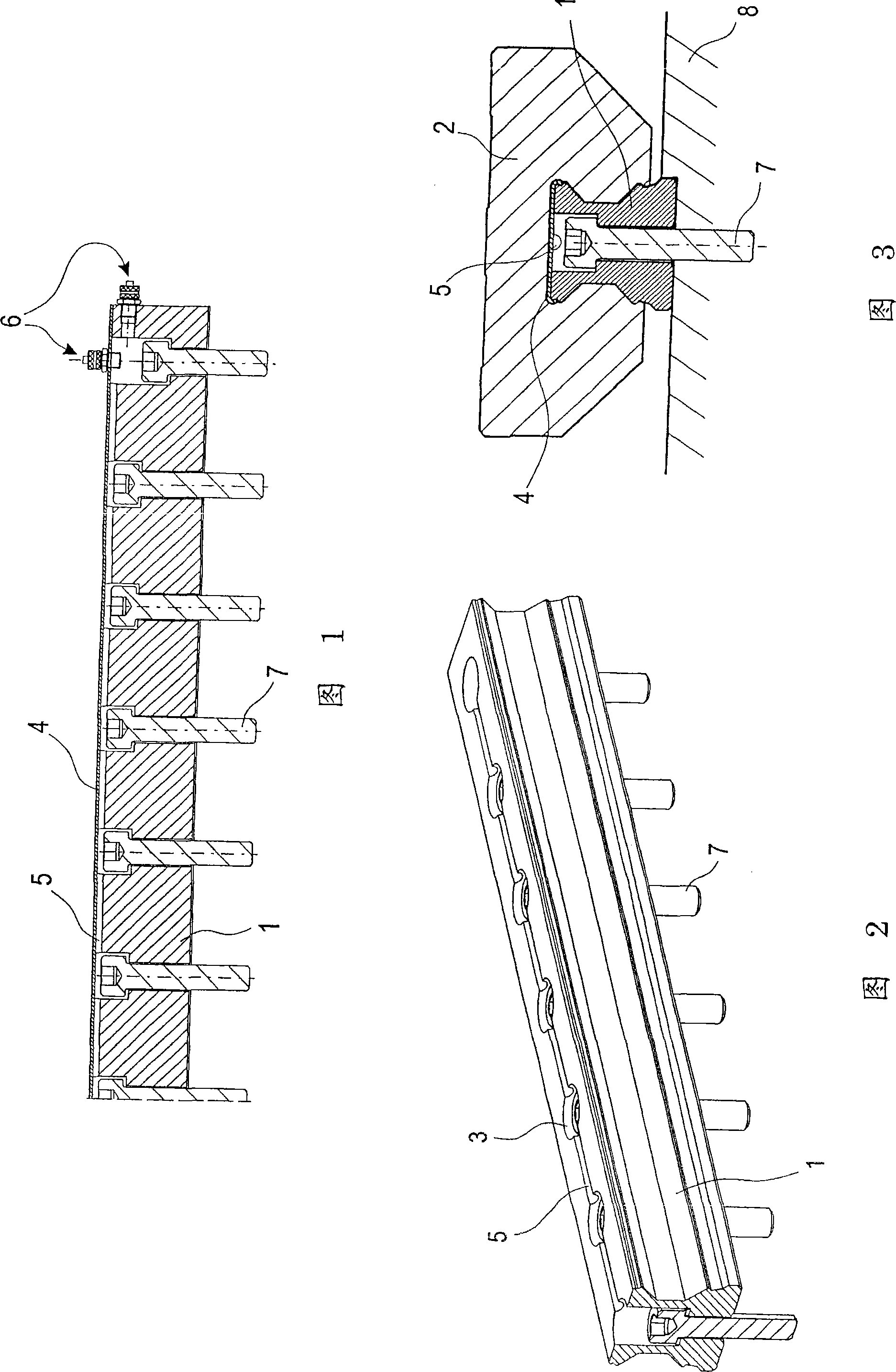

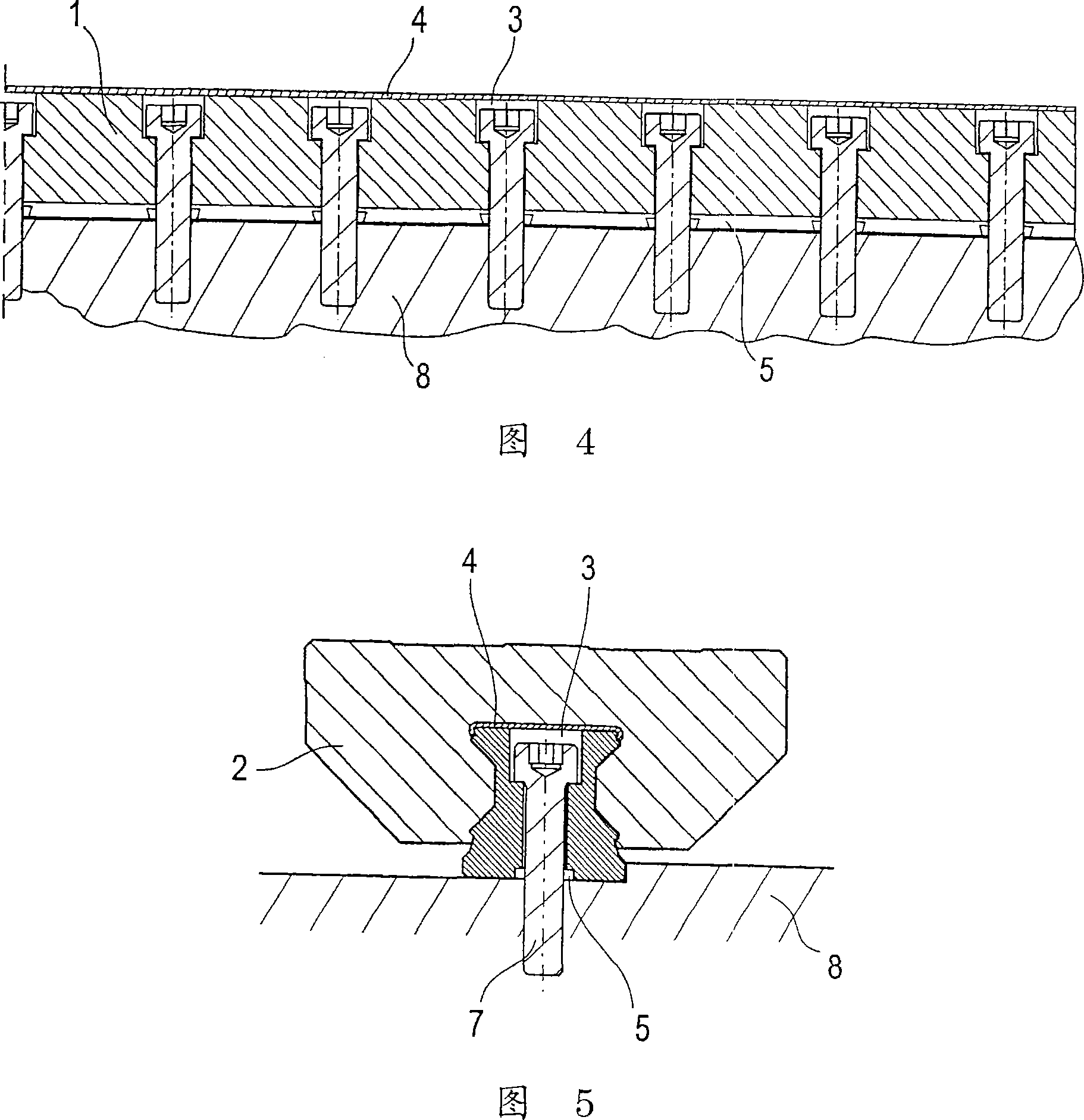

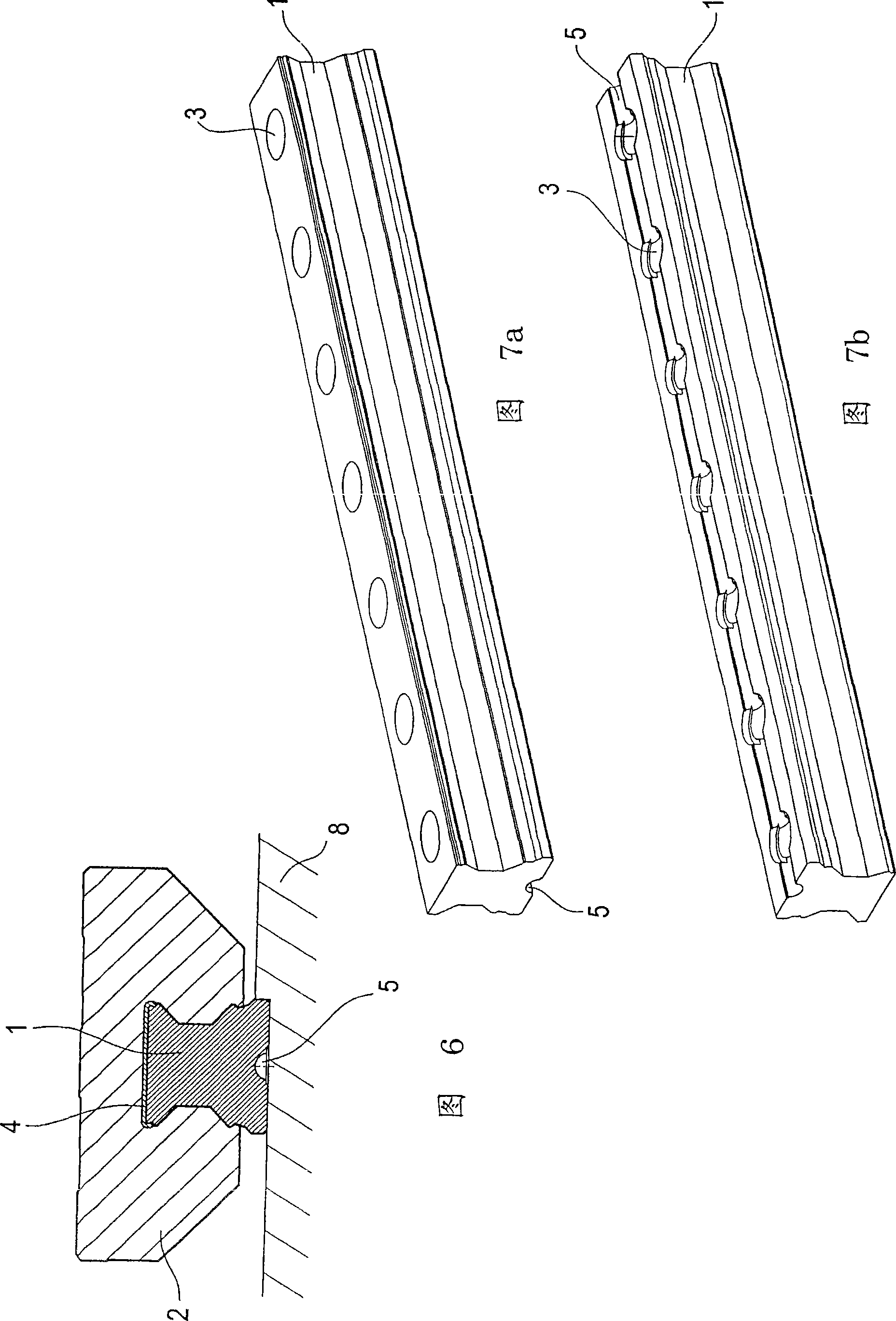

[0045] The linear guide 1 is provided with a protective strip 4 which forms a plane and covers the mounting recess 3 so that no dirt, debris, etc. can penetrate into the gap between the linear guide and the trolley 2 linearly moving on this guide (see image 3 ). In particular, since rolling elements (balls, rollers, etc.) are known from the prior art, in image 3 The illustration of the rolling elements (balls, rollers, etc.) is omitted in the illustration. The same applies to the trolleys and other constructional embodiments of the linear guide rail.

[0046] According to the invention, a coolant groove 5 is provided on the upper side of the linear rail, which groove extends along the length of the rail so as to connect with the mounting recess 3 . Coolant can be supplied or discharged by means of a coolant port 6 mounted to the upper or front side of the linear guide rail. exist figure 1 In the exemplary embodiment shown, for example, the right-hand screw 7 is counters...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com