Floating wind turbine installation

A technology for wind turbines and equipment, applied in mechanical equipment, wind turbines, wind turbine components, etc., can solve problems such as difficulties, and achieve the effects of large displacement, high strength, and low labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

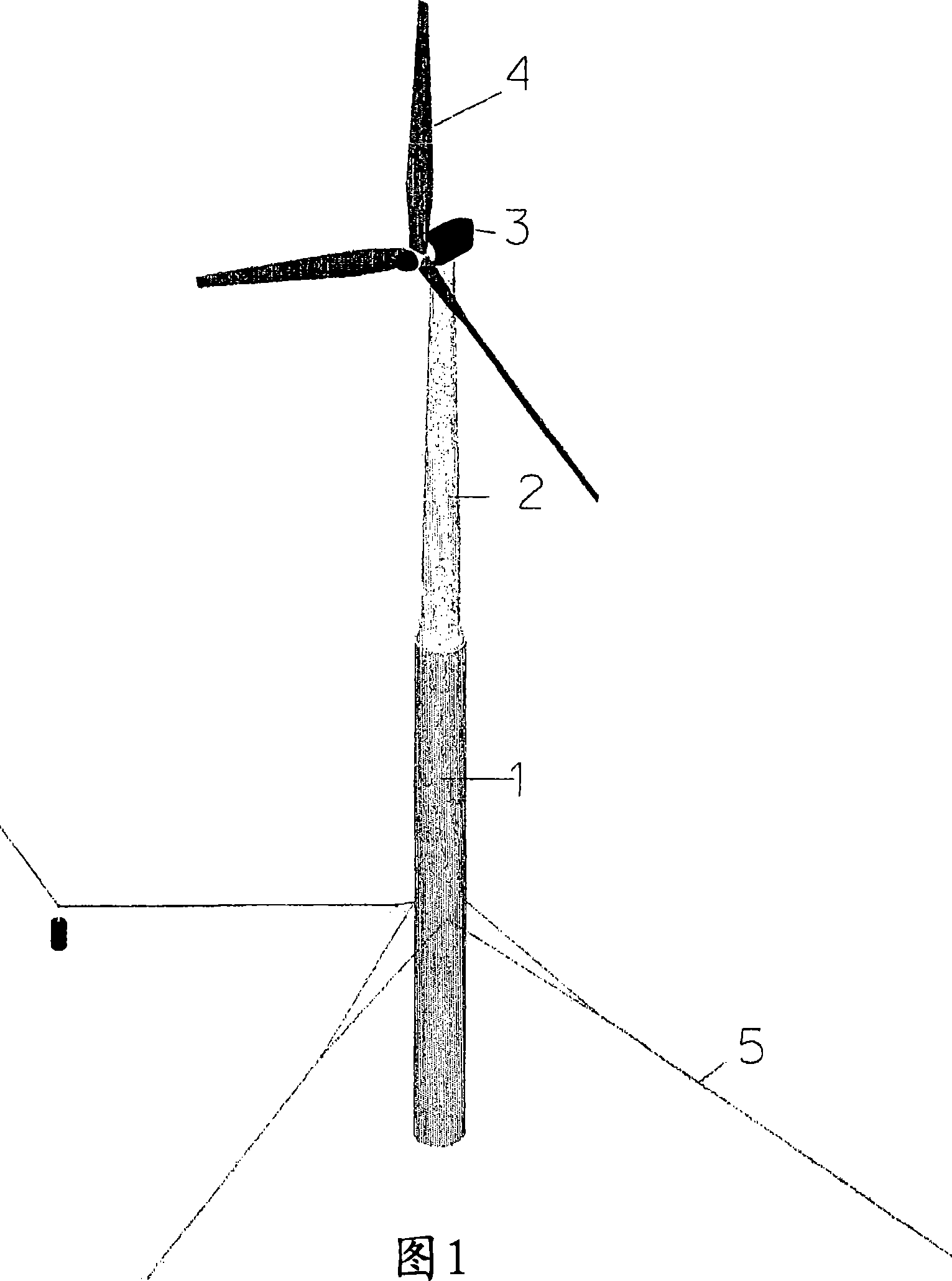

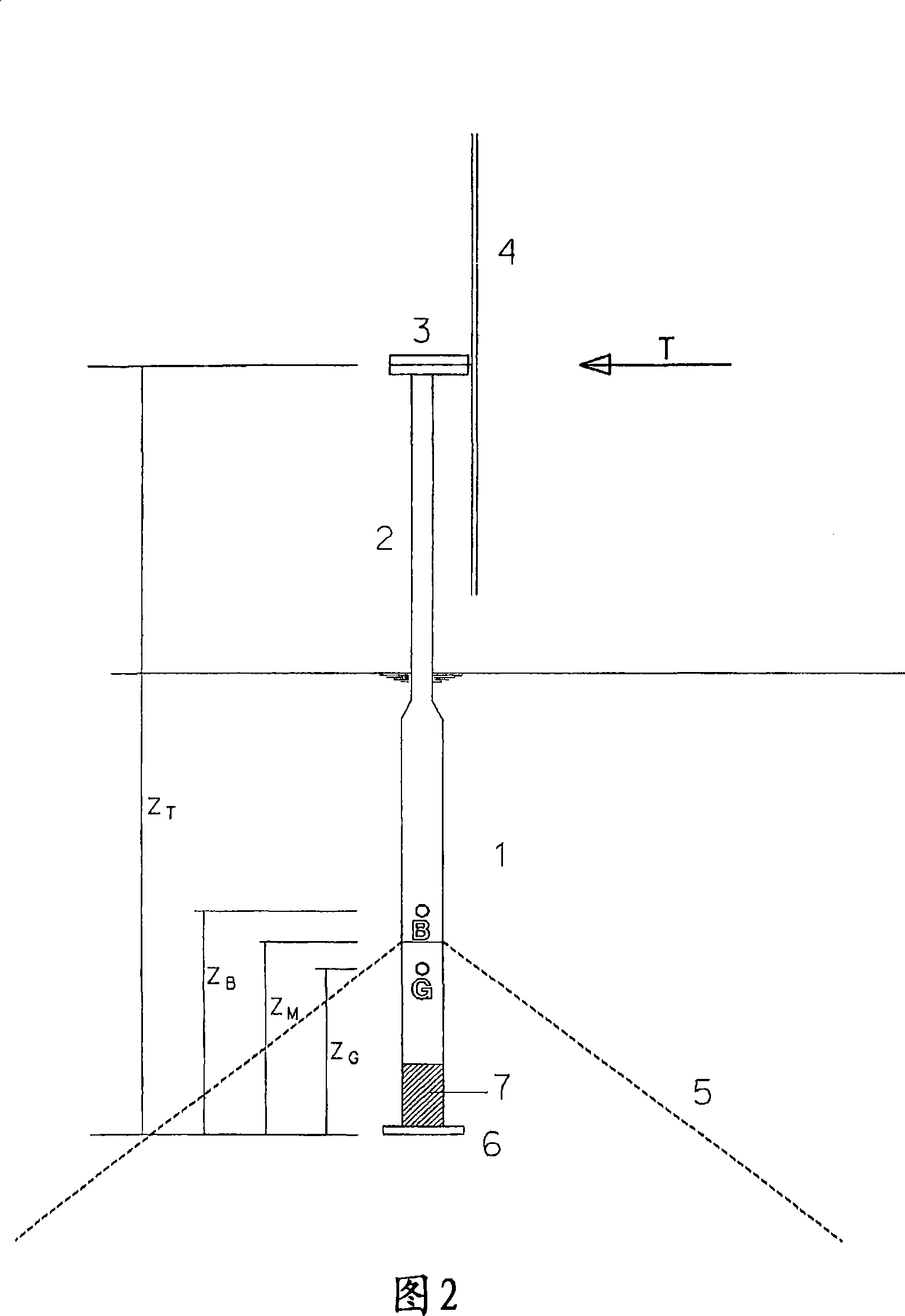

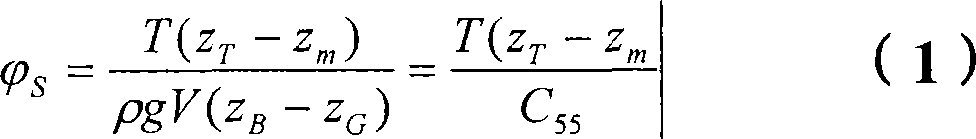

[0017] As shown in Figures 1 and 2, a floating wind turbine installation mainly includes an anchored floating foundation or floating base 1 supporting a tall tower 2 on top of which a turbine is mounted, and a turbine generator housing 3 and a rotor 4, said generator housing 3 enclosing a power generation unit (not shown), and the rotor 4 is arranged to be connected to said power generation unit. The floating base itself, which moves with the waves, is a major negative for the operation of the turbine and the loads placed on the tower. Another factor is that due to limited stability, the wind turbine installation also tends to tip when subjected to wind forces.

[0018] Therefore, the main challenges associated with the development of floating wind turbine installations are to minimize their movement in waves and achieve optimal stability while keeping their costs low.

[0019] Said costs are related to the size of the equipment. Therefore, a general attempt is made to reali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com