Chucking appliance

A clamp and movable clamp technology, applied in the direction of friction-clamped detachable fasteners, clothing, connecting components, etc., can solve the problems of easy rust, increased assembly time, no self-locking function, etc., to achieve a wide range of applications, Easy to use, firm grip

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing:

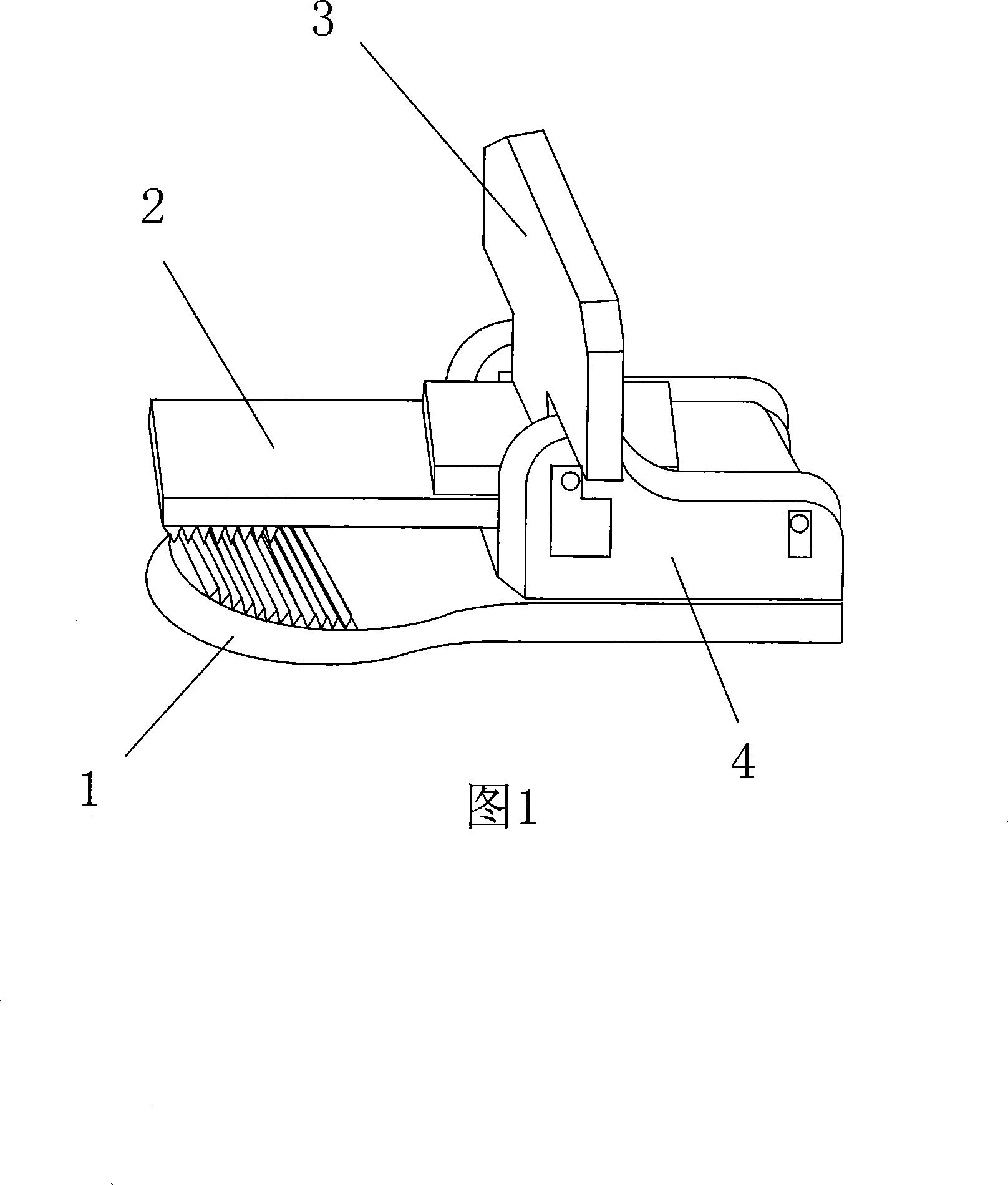

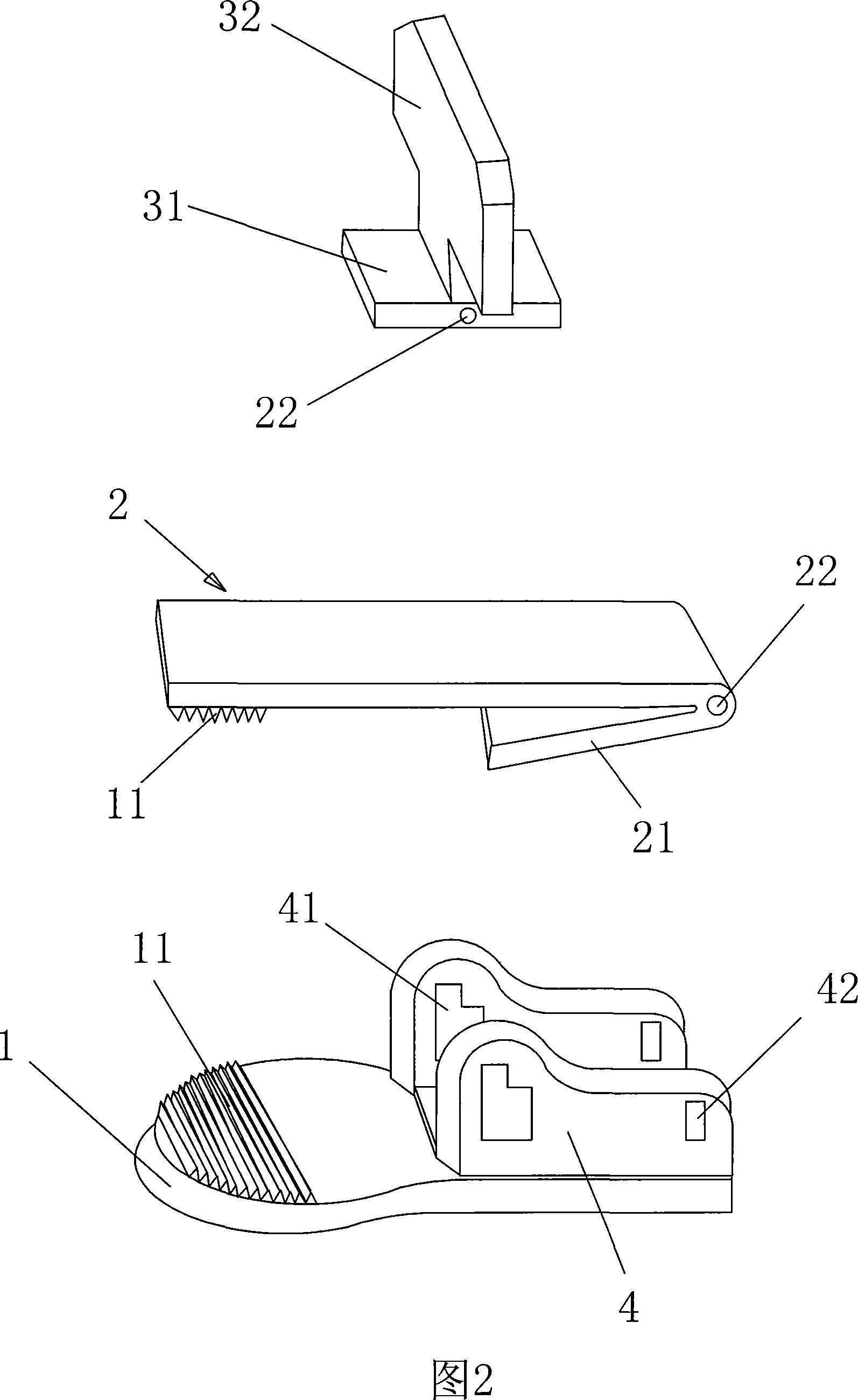

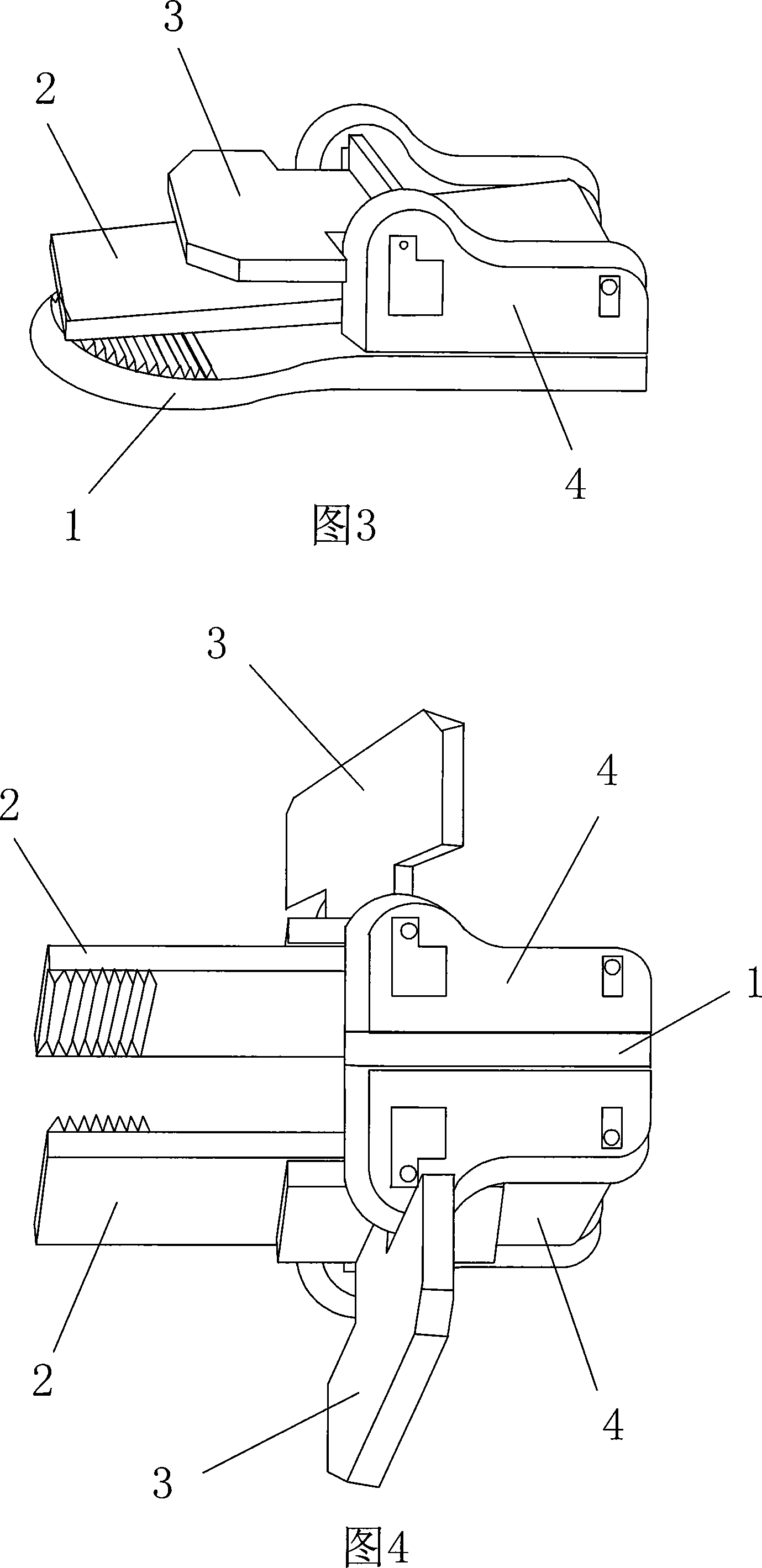

[0022] As shown in the figure, the fixture is divided into single-sided fixture and double-sided fixture. The single-sided fixture is mainly composed of a fixed clamping plate 1, a movable clamping plate 2, and a pressing plate 3. The rear part of the fixed clamping plate 1 is fixed with Two symmetrical brackets 4 have a pressing plate mounting groove 41 and a movable clamping plate mounting groove 42 on the bracket 4; the movable clamping plate 2 is approximately V-shaped in shape, and the V-shaped is composed of one side long and one short side, and the short side Supported on a fixed clamping plate, it has elasticity, and there is a hinge shaft 22 at the top of the V-shaped plate; the pressing plate 3 is composed of a horizontal plate 31 and a vertical plate 32 (approximately T-shaped), and the vertical plate 32 is in the middle of the horizontal plate 31 position, the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com