Regulation and control of lincomycin course of fermentation by using ammonium ion and improvement of lincomycin volume of production

A lincomycin, ammonium ion technology, applied in the directions of fermentation, microorganisms, biochemical equipment and methods, etc., can solve the problems of complex fermentation process, research on lincomycin, and inability to give full play to the production potential of Streptomyces lincosides.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 150L

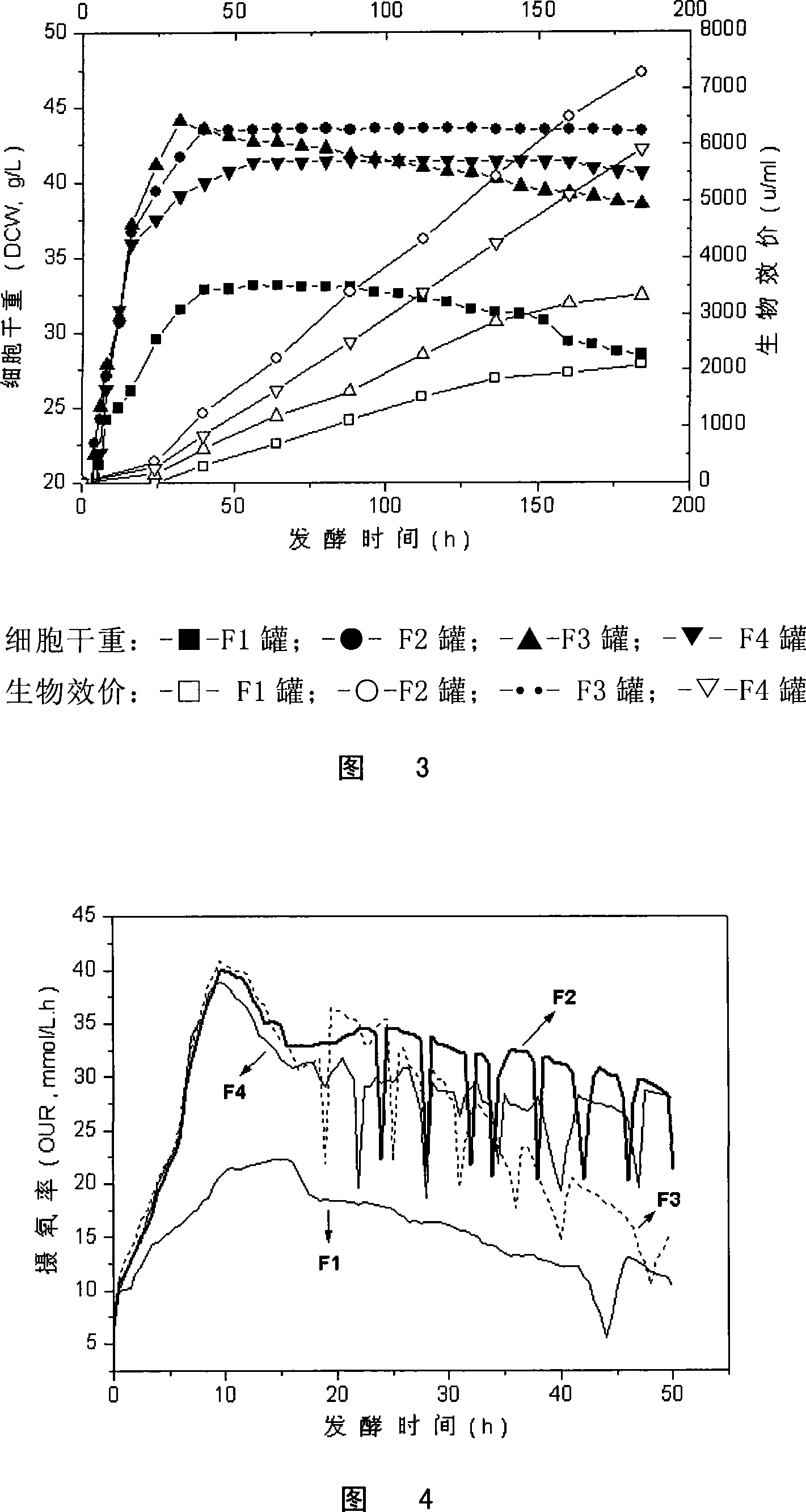

[0064] Embodiment 150L fermenter cultivation

[0065] The inoculum size is 20%; the air volume (VVM) per minute per unit volume (L) of the fermentation broth is 1.4L; the stirring speed is 300-550r / min; the culture temperature is 30°C; the tank pressure is 0.05MPa; the initial culture fluid volume is 30L ; Culture period 184h.

[0066] test methods

[0067] Dry cell weight (DCW): Take 10ml of fermentation broth, weigh it wet, filter it with Buchner funnel, wash the wet solid three times with water, dry at 80°C for 12 hours, weigh it, and calculate DCW (g / L).

[0068] Lincomycin Potency: Chinese Pharmacopoeia (2005 Edition) Part Two Regulations.

[0069] NH 4 + Content: Determination of ammonium ion by phenol-hypochlorite reaction [see: Xu Chendong et al., Discussion on the method of determination of ammonium ion by phenol-hypochlorite reaction [J]; Journal of Wuxi Light Industry University: Food and Biotechnology, 1998, 17(1):34-38].

[0070] Amino nitrogen (NH 2 -N) co...

Embodiment 2

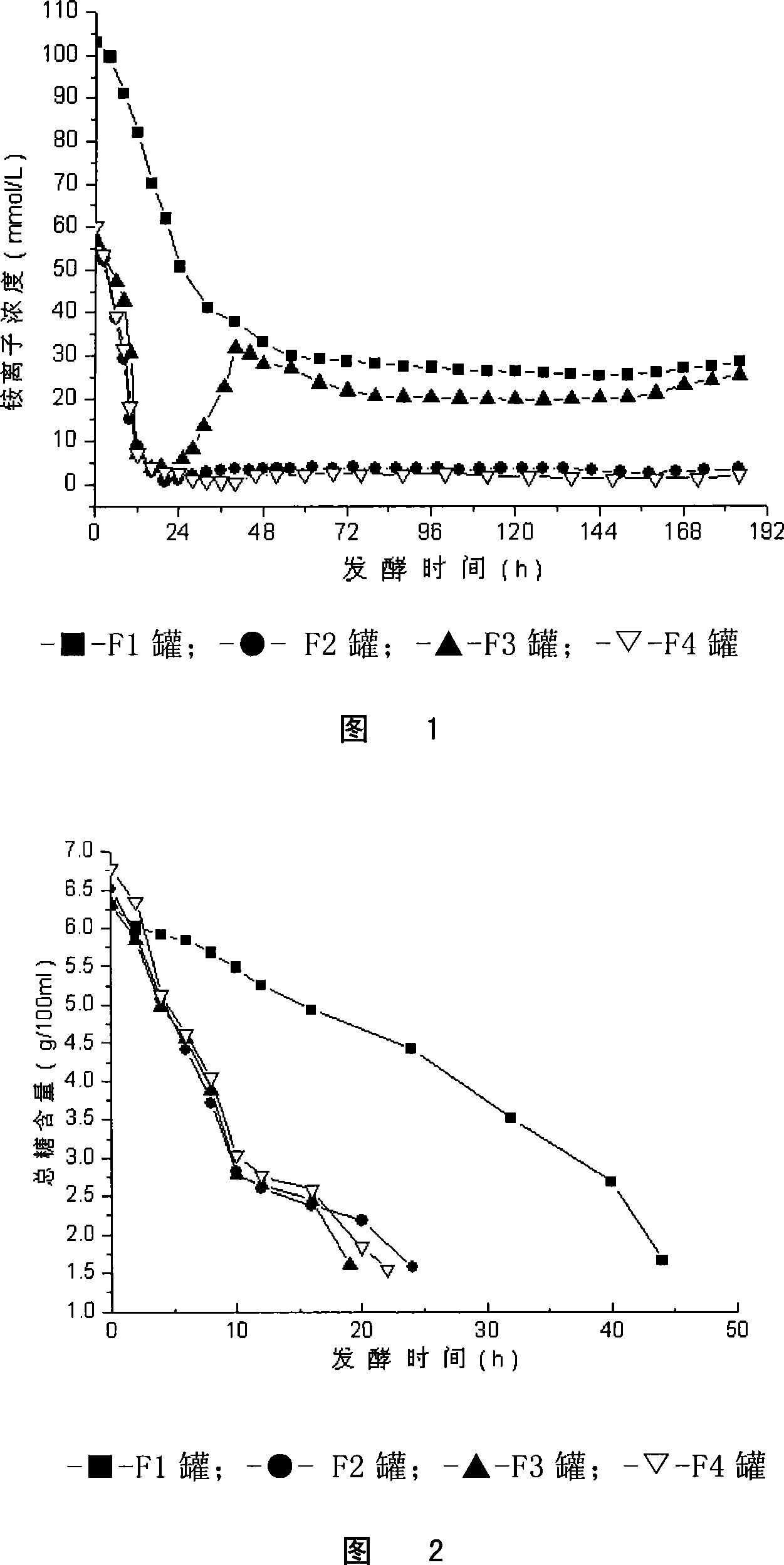

[0072] Example 2NH 4 + Dynamic effects on nitrogen source metabolism

[0073] The inventors have identified four typical supplemental ammonium sulfate regimens (Table 1) to investigate NH 4 + effect on the fermentation process. In order to investigate the NH in the basal medium 4 + Changes in the fermentation process when the content is higher, the content of ammonium sulfate in the F1 tank basal medium is set to 7g / L (equivalent to 103.139mmol / L); For the dynamic change of the process, the feeding process of F3 tank was designed; in order to investigate the dynamic change of the fermentation process in the early stage of fermentation and when the rate of ammonium sulfate feeding was low, the feeding process of F4 tank was designed. where [NH 2 -N], check every 2 hours.

[0074] Feeding process scheme of table 1 ammonium sulfate

[0075] tank number

0h [NH 4 + ]

Ammonium Sulfate Supplementation Protocol

F1

103.139mmol / L

[NH 2 -N...

Embodiment 3

[0084] Example 3NH 4 + Dynamic effects on glucose metabolism

[0085] According to the measurement, at 0 hour, the total sugar content of the 4 tanks of culture fluid were 6.3, 6.52, 6.32 and 6.78g / 100ml respectively. Before 16h, the total sugar consumption rate of tanks F2, F3 and F4 changed basically the same. After 16 hours, ammonium sulfate was supplemented according to Table 1: both tanks F3 and F4 began to replenish ammonium sulfate for the first time at 16 hours, and the rate of ammonium sulfate supplementation in the former was lower than that in the former. The former is larger, resulting in the former's total sugar consumption rate being greater than the latter; the F2 tank begins to add ammonium sulfate at 20h, and at 16-20h, its NH 4 + The concentration was lower than that of F3 and F4 tanks, and the rate of total sugar consumption was also lower (Fig. 2), indicating that NH 4 + Concentration is positively correlated with enzyme activity of glucose degrading e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com