Shuttle type reducing check valve

A check valve and reducing technology, applied in the direction of control valve, valve device, functional valve type, etc., can solve the problems of low disassembly and assembly accuracy and sealing reliability of valve core components, short service life, complex structure, etc. Light weight, easy disassembly and assembly, small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

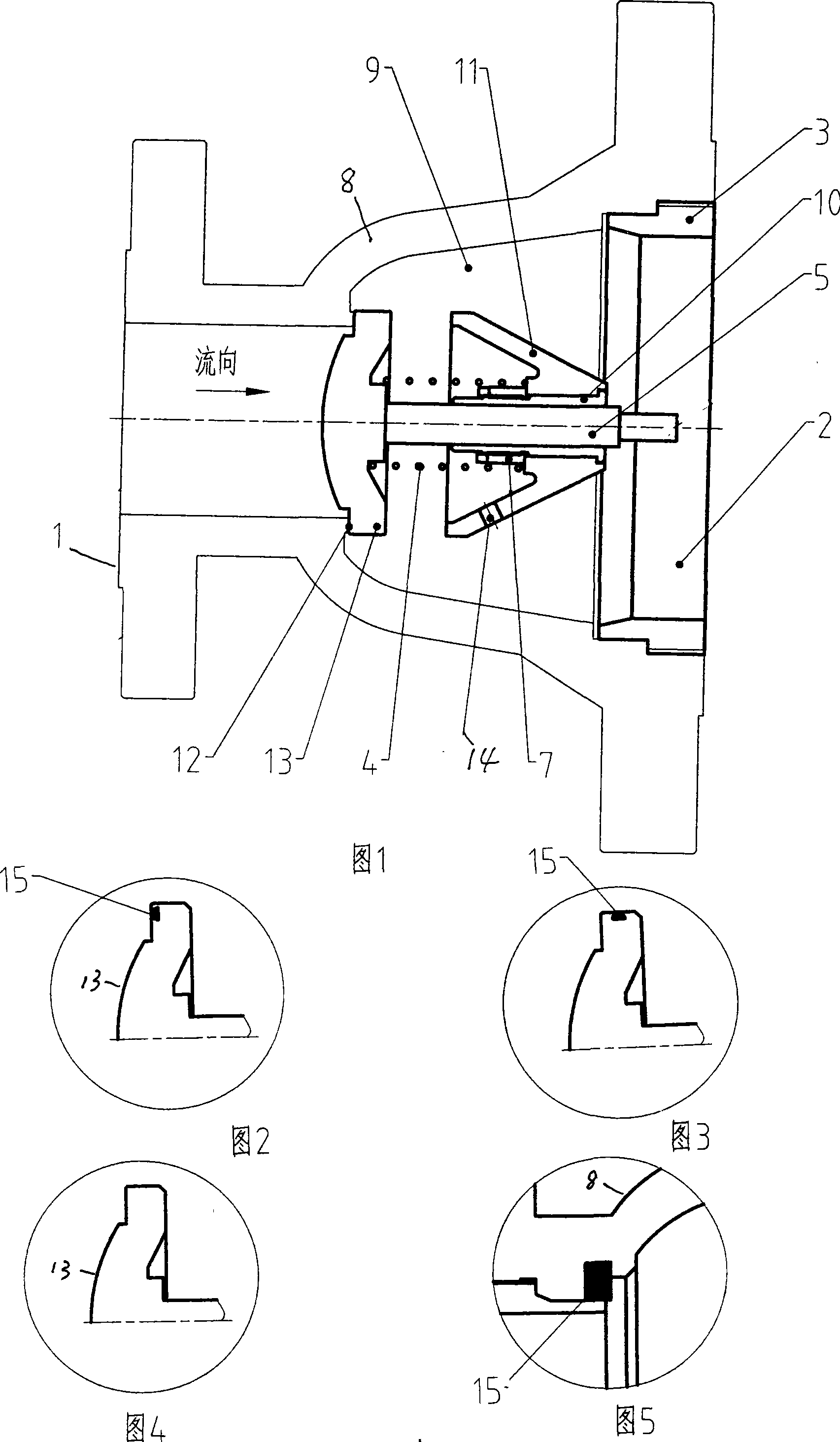

[0020] The inner cavity of the shuttle check valve with different diameters starts from the end face of the valve seat, and is connected to the flange at the other end as a streamlined diffusion cone. The two ends are channels and flanges with different diameters, which meet the different diameter connection requirements of the system. Require.

[0021] The outlet flange of the water pump is connected to the small flange end (inlet end) of the different diameter check valve, and the delivery pipe

[0022] The pipe is connected to the large flange end (outlet end) of the reducing check valve. This not only realizes the non-return function, but also

[0023] Realized the function of different diameter connection.

[0024] The inner cavity of the flange at the right end of the housing 8 is threadedly connected with the lining ring 3, and the valve sleeve 11 is connected with the lining ring 3 to form a closed cavity with the valve disc 13. There are springs 4 sleeved on the val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com