Tiny oil ignition whirlwind coal dust burner suitable for meager coal and anthracite coal

A pulverized coal burner and micro-oil ignition technology, which is applied in the direction of burners, burners, and combustion methods for burning powder fuels, can solve the problems of low oil-saving rate of micro-oil ignition system, low pulverized coal burnout rate, and unit safety. Hidden dangers and other problems, to achieve the effects of small resistance, improved burnout rate, and high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

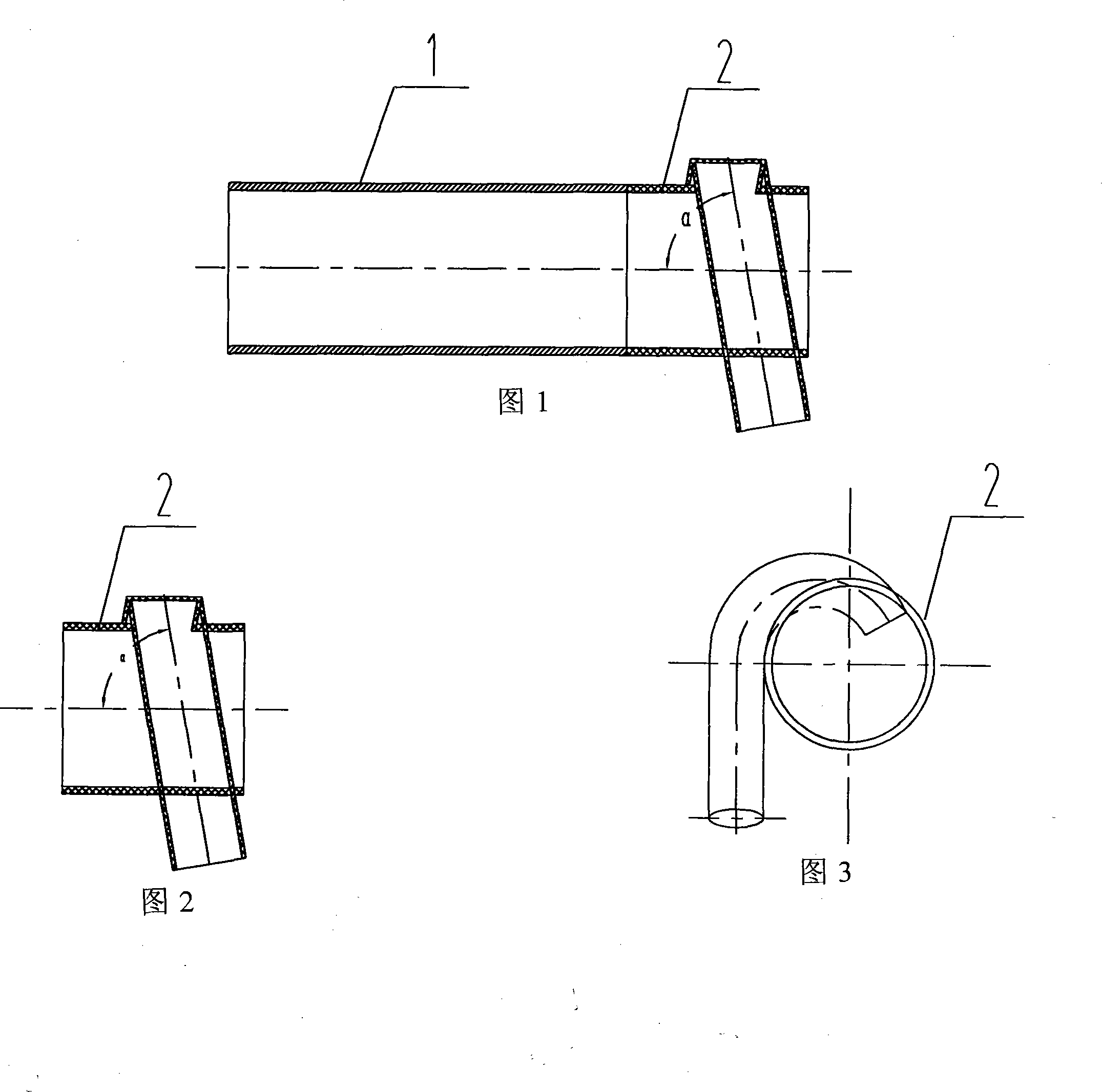

[0017] The concrete structure of the present invention is referring to Fig. 1. The burner barrel 1 of the oil-less ignition cyclone pulverized coal burner is made of refractory material. The cyclone volute 2 is also made of refractory material, which plays the role of high temperature resistance. The burner barrel 1 and the cyclone volute 2 are connected together or have an integrated structure, and their central axes coincide. The high-temperature oil flame in the air inlet of the cyclone volute 2 enters the burner cylinder 1 tangentially along the cylinder wall, so that the high-temperature oil flame spirals forward along the central axis in the burner cylinder, thereby forming a cyclone combustion. The structural design of the cyclone volute 2 plays a role in allowing the high-temperature oil flame to rotate and move forward in the burner barrel 1 .

[0018] The structure of the cyclone volute is shown in Figures 2 and 3. The diameter and length of the burner barrel 1 de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com