Few oil ignited coal powder burner for low grade coal

A technology of pulverized coal burner and less oil ignition, which is applied to burners, burners for burning powder fuel, combustion methods, etc., can solve problems such as poor combustion effect, and achieve the effects of high temperature resistance and improved burnout rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

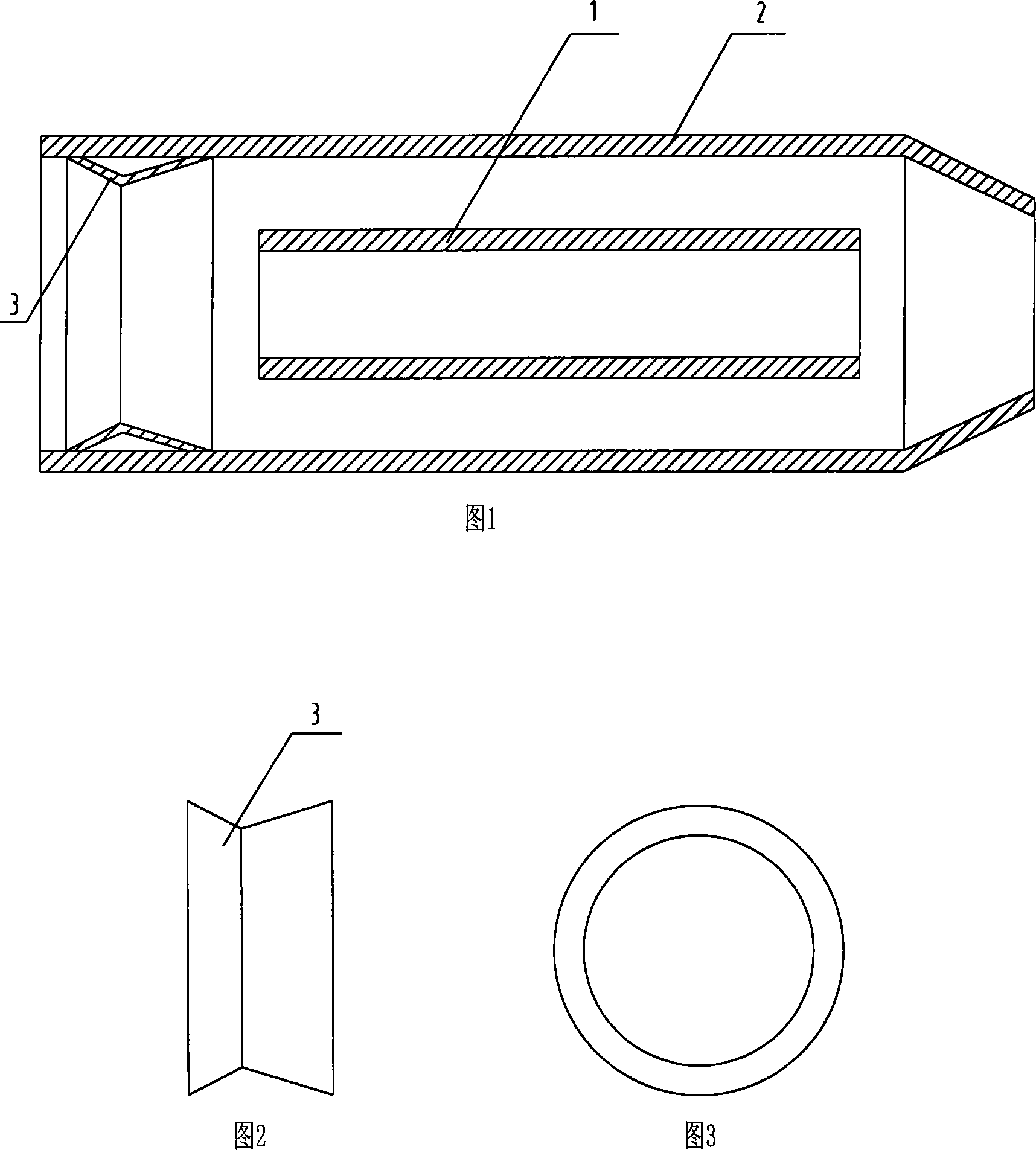

[0012] The concrete structure of the present invention is referring to Fig. 1. The central tube 1 of the main body of the oil-less ignition pulverized coal burner is made of refractory material. Outer sleeve 2 is cast by wear-resistant steel, plays certain wear-resistant function. The central cylinder 1 of the main body is placed in the outer sleeve 2, and their central axes coincide. An annular thickening block 3 is fixed inside the barrel on the mouth side of the outer sleeve 2, the outer peripheral side surface of the annular thickening block is nested with the inner wall of the outer cylinder, and the inner peripheral side surface forms a triangular slope along the direction of the central axis. structure. See Figure 2 and Figure 3 for the structure of the shade block. The thickness block 3 on the outer sleeve plays the role of introducing the outer layer of pulverized coal into the center of the flame. Because it is in direct contact with the flame, it is made of heat-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com